Biological humic acid fertilizer and preparing method thereof

A biological humic acid and fertilizer technology, applied in the field of agricultural biology, can solve the problems of polluting the environment and wasting resources, and achieve the effects of promoting plant growth, improving conversion rate, and improving the level of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

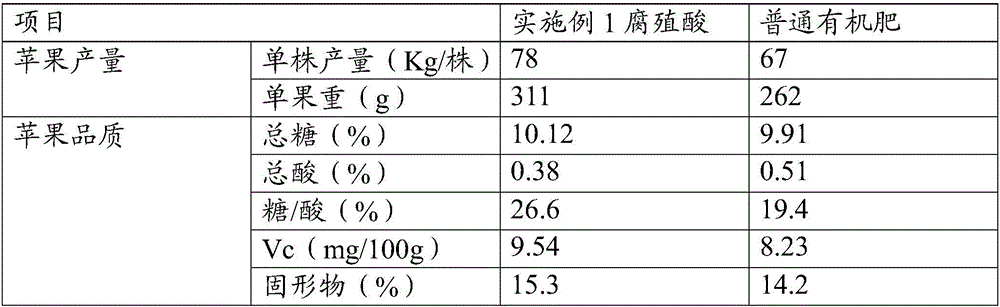

Examples

Embodiment 1

[0029] A kind of biological humic acid fertilizer, its main raw material is calculated by weight:

[0030] 70 parts of edible mushroom bran, 20 parts of apple pomace, 1 part of soybean molasses, 1 part of conditioner, 0.1 part of compound enzyme, 0.1 part of compound bacterial agent;

[0031] The edible fungus chaff is derived from the chaff of oyster mushrooms, shiitake mushrooms, enoki mushrooms, pleurotus eryngii or ganoderma lucidum; its main cultivation substrates are cottonseed hulls, bean straw, sawdust, wood chips, etc.;

[0032] The enzyme system in the compound enzyme is composed of cellulase 12500u / g, protease 2500u / g, mannanase 5000u / g, xylanase 10000u / g;

[0033] The apple pomace is the residue obtained after apple juice is squeezed, and the weight percentages of its moisture, protein and crude fiber are controlled at 9.1%, 6.2% and 15.3%;

[0034] The soybean molasses is purchased from Tianjin Ennong Feed Technology Co., Ltd., and its main nutritional components...

Embodiment 2

[0046] A kind of biological humic acid fertilizer, its main raw material is calculated by weight:

[0047] 80 parts of edible fungus chaff, 30 parts of apple pomace, 2 parts of soybean molasses, 2 parts of conditioner, 0.2 part of compound enzyme, 0.2 part of compound bacterial agent;

[0048] The edible fungus chaff is derived from the chaff of oyster mushrooms, shiitake mushrooms, enoki mushrooms, pleurotus eryngii or ganoderma lucidum; its main cultivation substrates are cottonseed hulls, bean straw, sawdust, wood chips, etc.;

[0049] The enzyme system in the compound enzyme is composed of cellulase 25000u / g, protease 5000u / g, mannanase 10000u / g, xylanase 20000u / g;

[0050] The apple pomace is the residue obtained after apple juice is squeezed, and the weight percentages of its moisture, protein and crude fiber are controlled at 9.1%, 6.2% and 15.3%;

[0051] The soybean molasses is purchased from Tianjin Ennong Feed Technology Co., Ltd., and its main nutritional componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com