Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

A gas ash, zinc and iron technology, applied in the field of secondary resource recycling in metallurgical processes, can solve problems such as corrosion, high technology development costs, difficult recovery and treatment, etc., to improve economic benefits, eliminate high fuel costs, and improve comprehensive Use level effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

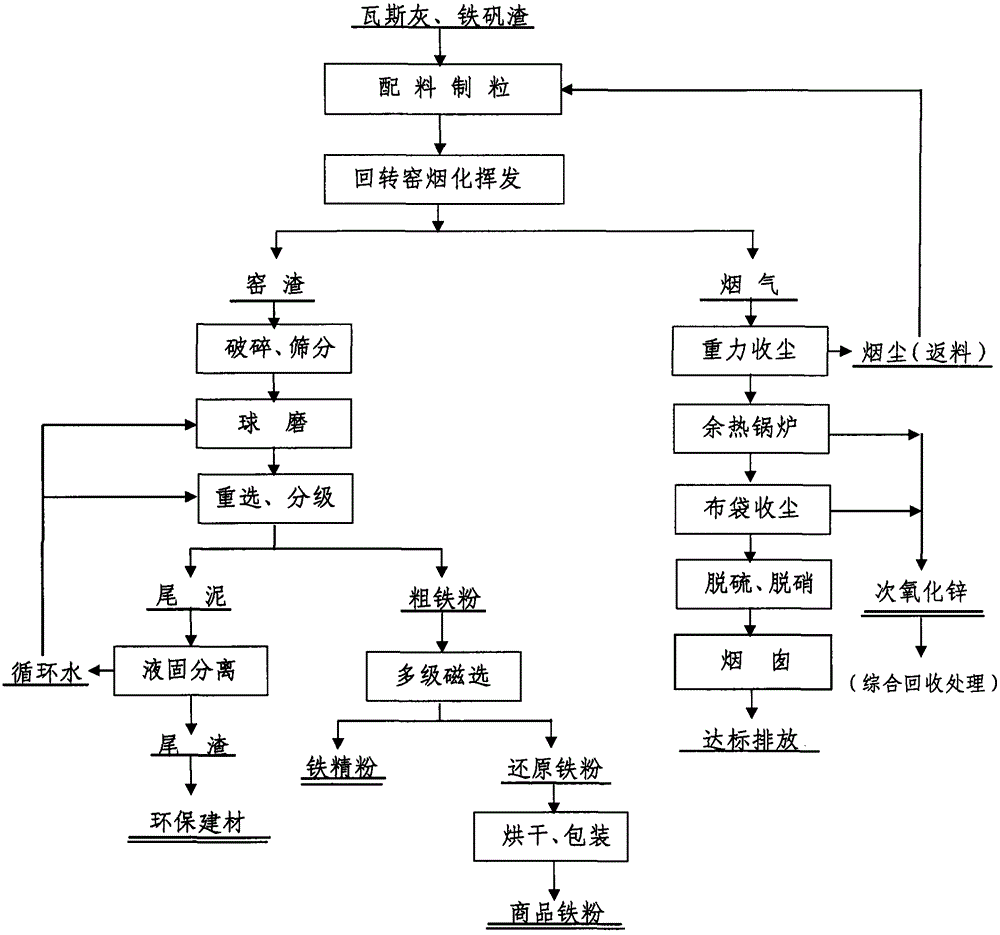

Method used

Image

Examples

Embodiment 1

[0057] The ingredients used are:

[0058] The raw material composition of steel plant gas ash (mud) is (wt,%): Fe28.4, C21.3, Zn10.4, Pb0.6, In0.08, Bi0.3, CaO5.27, SiO 2 8.14, Al 2 o 3 3.65,H 2 O16.3%;

[0059] Raw material composition of jarosite slag of zinc smelter is (wt,%): Zn6.35, Pb1.8, In0.10, Fe32.7, Cu0.12, Cd0.018, As0.6, Mn0.62, Ag87g / t,H 2 O21.8%;

[0060] Composition of coke powder: fixed carbon 68.5%, volatile matter 4.68%, ash content 28.7%, S0.45%, H 2 O12%, calorific value 6300KCal / Kg; particle size <10mm (of which <2mm accounts for 75%);

[0061] Quicklime composition: ordinary metallurgical lime grade 3, CaO content > 85%, particle size 60-80 mesh;

[0062](1) Batching and granulation First, mix the above-mentioned components of gas ash and alum slag in a ratio of 3:1, and then mix the mixture with coke powder and quicklime in a ratio of 1:0.18:0.03 with a grab bucket crane for batching , after mixing evenly, it is sent to a φ6000×500mm disc gran...

Embodiment 2

[0068] The ingredients used are:

[0069] The raw material composition of steel plant gas ash (mud) is (wt,%): Fe18.6, C19.3, Zn8.4, Pb0.3, In0.06, Bi0.1, CaO6.18, SiO 2 10.36, Al 2 o 3 4.19, H 2 O17.5%;

[0070] Raw material composition of jarosite slag from zinc smelter is (wt,%): Zn5.68, Pb2.7, In0.08, Fe35.1, Cu0.07, Cd0.021, As0.4, Mn0.37, Ag126g / t,H 2 O23.8%;

[0071] Composition of coke powder: 70.1% fixed carbon, 3.21% volatile matter, 26.3% ash, 0.38% S, H 2 O14%, calorific value 6500KCal / Kg; particle size <10mm (of which <2mm accounts for 80%);

[0072] Quicklime composition: ordinary metallurgical lime grade 3, CaO content > 85%, particle size 60-80 mesh;

[0073] (1) Batching and granulation First, mix the above-mentioned gas ash and alum slag in a ratio of 5:1, then mix the mixture with coke powder and quicklime in a ratio of 1:0.20:0.02 with a forklift, and mix well Finally, it is sent to a φ6000×500mm disc granulator through a disc feeder and a belt co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com