Method for improving rice protein functional property with protein-polysaccharide graft coupling technology

A rice protein and protein technology, which is applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problem of little research on damp-heat reaction, and achieve the effect of improving functional properties, improving utilization level, and huge market potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

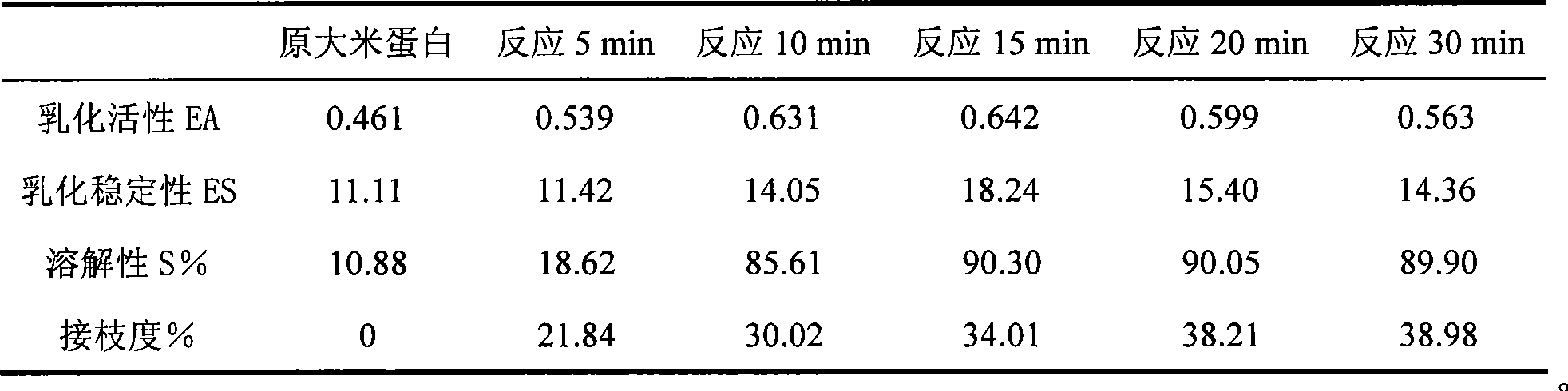

Embodiment 1

[0016] Weigh a certain amount of rice protein, add deionized water (prepared to 1.2% w / v protein solution), adjust the pH to 12 with NaOH, magnetically stir in a water bath at 50°C to dissolve the protein, then cool the sample to room temperature, press a certain Add glucose in proportion to make the protein-glucose mass ratio 1:1, stir for 20 minutes to fully mix the protein / sugar, adjust the pH to 11 with acid and alkali, heat the mixture to 90°C and keep stirring, keep it warm for 15 minutes Immediately put it into an ice bath to cool for 5 minutes, freeze-dry the reacted mixed solution until the water content drops below 10%, and obtain the modified rice protein product.

Embodiment 2

[0018] Weigh a certain amount of rice protein, add deionized water (prepared to 1.2% w / v protein solution), adjust the pH to 12 with NaOH, magnetically stir in a water bath at 50°C to dissolve the protein, then cool the sample to room temperature, press a certain Add lactose in proportion to make the protein-lactose mass ratio 1:1, stir for 20 minutes to fully mix the protein / sugar, adjust the pH to 11 with acid and alkali, heat the mixture to 90°C and keep stirring, keep warm for 15 minutes Immediately put it into an ice bath to cool for 5 minutes, freeze-dry the reacted mixed solution until the water content drops below 10%, and obtain the modified rice protein product.

Embodiment 3

[0020] Weigh a certain amount of rice protein, add deionized water (prepared to 1.2% w / v protein solution), adjust the pH to 12 with NaOH, magnetically stir in a water bath at 50°C to dissolve the protein, then cool the sample to room temperature, press a certain Add maltodextrin in proportion to make the mass ratio of protein to maltodextrin 1:1, stir for 20 minutes to fully mix protein / sugar, adjust pH to 11 with acid and alkali, heat the mixture to 90°C and keep stirring After 20 minutes of heat preservation, immediately put it into an ice bath to cool for 5 minutes, freeze-dry the reacted mixed solution until the water content drops below 10%, and obtain the modified rice protein product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com