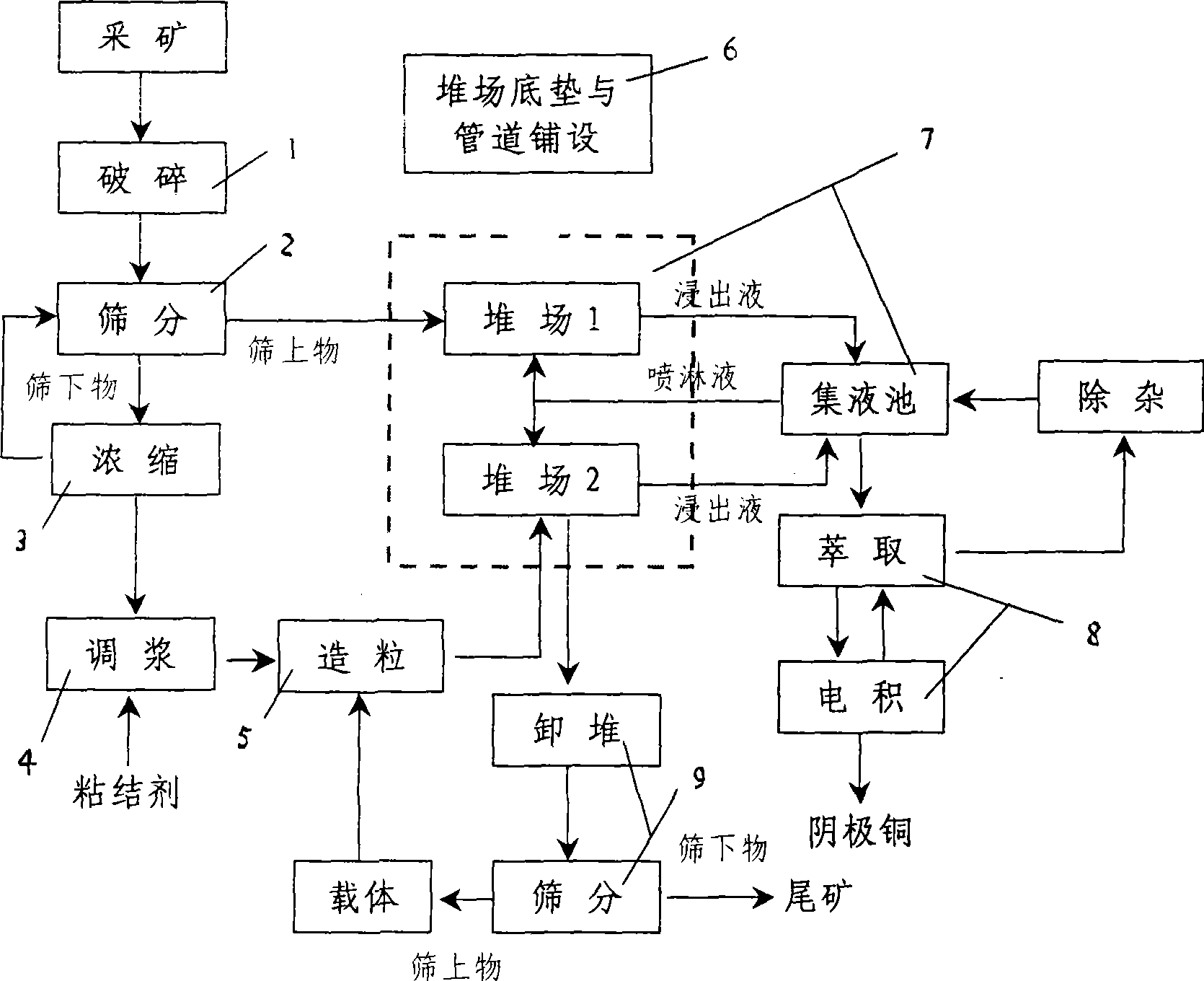

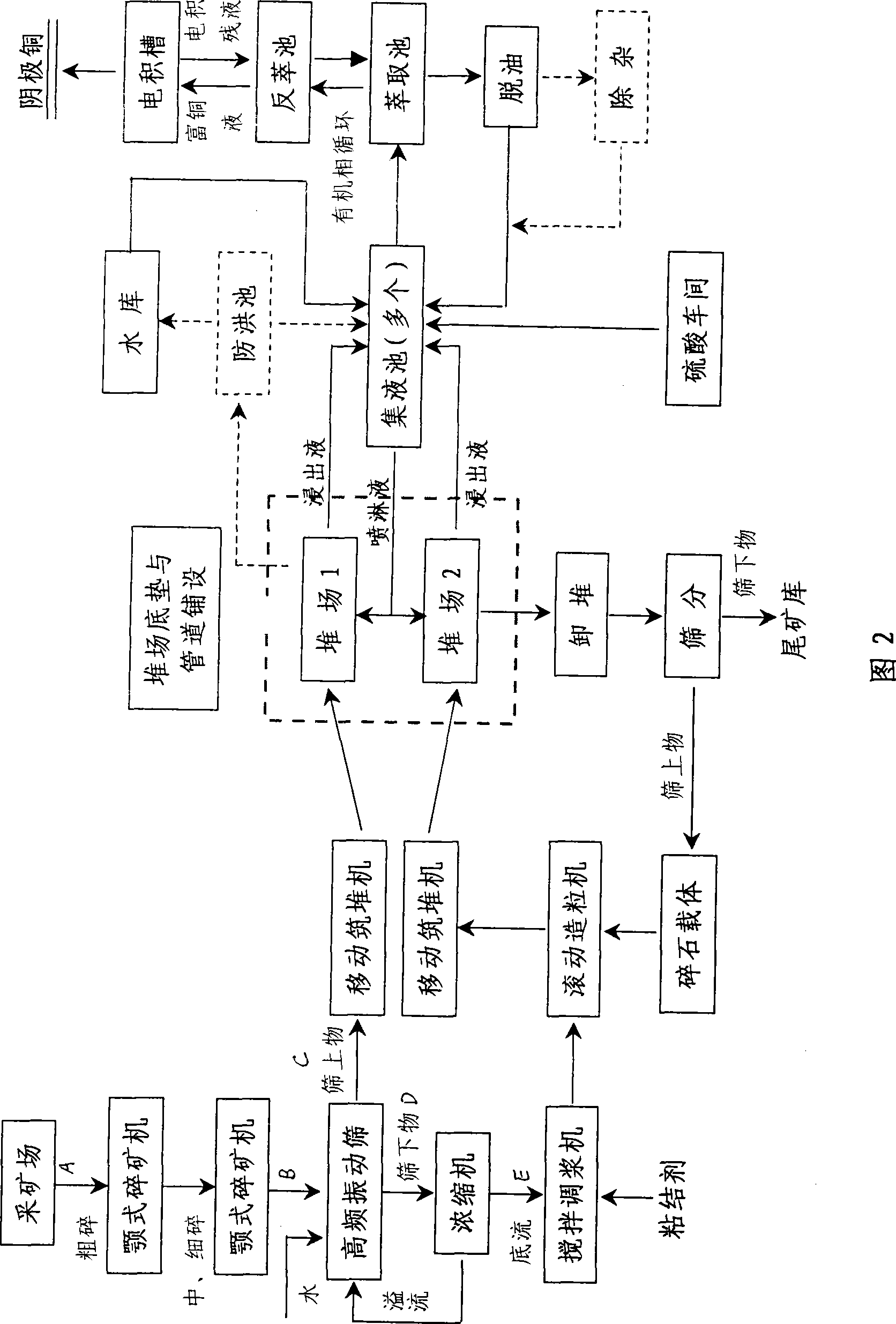

Acid heap leaching process for cupric oxide ore

A technology of copper oxide ore and new process is applied in the fields of energy saving, new technology of high-efficiency copper extraction, and environmental protection, which can solve the problems of low leaching rate, interference of ore sludge, and low recovery rate of sulfuration flotation, so as to reduce environmental pollution and improve economy. benefit, the effect of improving the level of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A domestic copper mine is a copper oxide deposit, and copper oxide minerals mainly exist in the form of malachite and azurite. In addition to copper minerals, the ore also contains a large amount of iron, which mainly exists in the form of limonite. The gangue minerals are mainly clay minerals, quartz and gypsum. Most of the gangue minerals are in the form of silt, with a soft and brittle structure. In the pores and gaps of the gangue minerals, there are often sporadic distributions of malachite and bluestone in a dispersed state. copper ore. Mineral composition in the ore: malachite and azurite 28%, limonite 35%, quartz 10%, iron stained clay mineral 20%, kaolin 5%, gypsum 2%.

[0028] Because there are many clay-like muddy minerals in the ore and the content of iron minerals is large, no matter whether the flotation process or the gravity separation process is used, the separation effect of copper is poor, and it is difficult to obtain good technical indicators.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com