System and method for cleaning and sterilizing related equipment in beer producing process

A technology for cleaning and disinfection, production process, applied in the direction of liquid cleaning methods, sanitary equipment, cleaning methods and utensils, etc., can solve problems affecting production efficiency, wasting resources, etc., to reduce the use of hot water, reduce purchase costs, The effect of saving water resources

Inactive Publication Date: 2012-03-21

BEIJING GRET RESOURCES ENVIRONMENTAL PROTECTION TECH

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This wastes resources on the one hand, and serious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

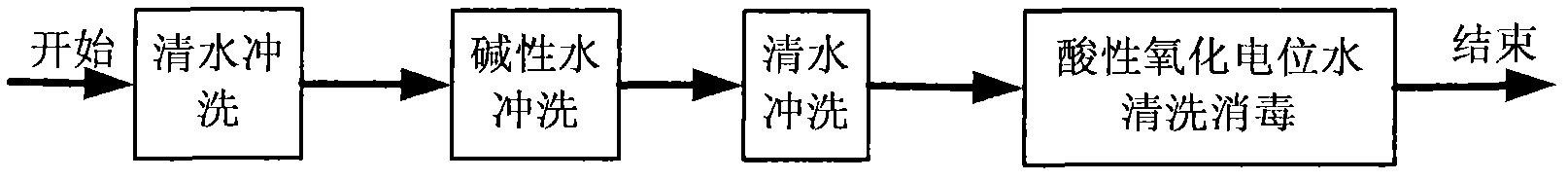

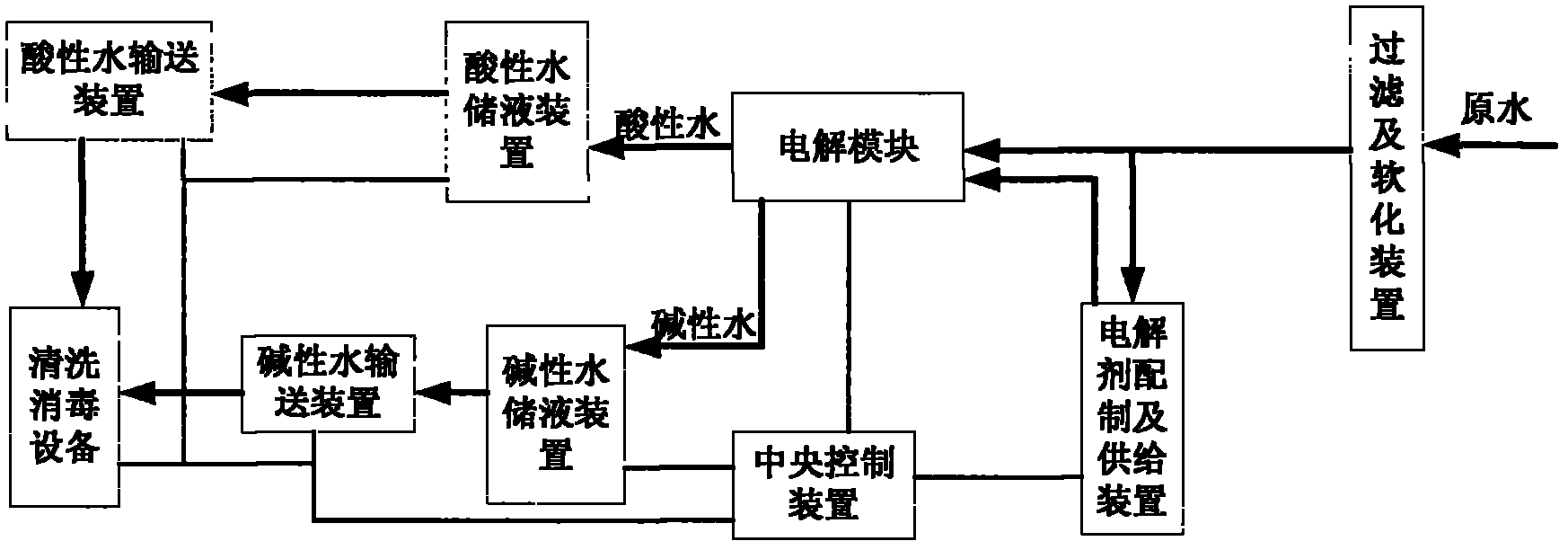

The invention provides a system and a method for cleaning and sterilizing related equipment in the beer producing process. The system that uses oxidation potential water to clean and sterilize the beer producing equipment comprises oxidation potential water generator equipment and cleaning and sterilizing equipment. The oxidation potential water generator equipment comprises a filtering and softening device, an electrolyzer preparing and supplying device, an electrolytic module, an acid water stock solution device, an alkaline water stock solution device, an acid water conveying device, an alkaline water conveying device, a central control device and an electric potential water physicochemical index detecting device. In the invention, acid oxidation potential water is adopted to replace original chemical disinfectant so as to realize sterilizing treatment on the related equipment, appliances and the like in the beer producing process; and compared with an original method that uses chemical disinfectant, the system and the method have obvious advantages.

Description

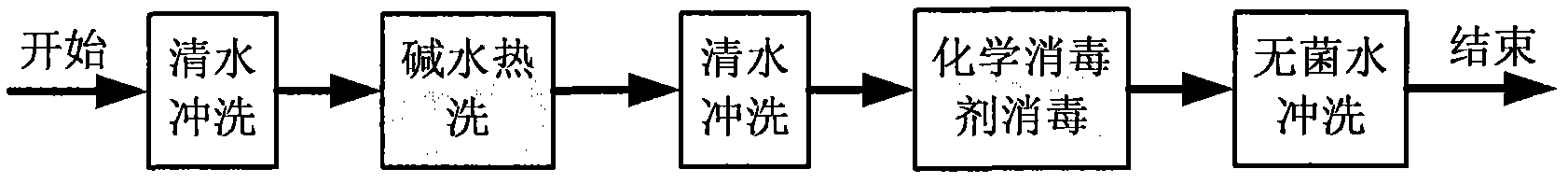

technical field [0001] The invention relates to a system and method for cleaning and disinfecting related equipment in the beer production process, in particular to a system and method for cleaning and disinfecting related equipment in the beer production process using oxidation potential water. Background technique [0002] Beer is rich in nutrition and low in alcohol concentration, so it is easily contaminated by microorganisms and the quality of beer is adversely affected. The main technological process of beer production in a modern brewery is divided into several processes such as malting, saccharification, fermentation, and canning. Contaminants in beer production mainly come from air, water, raw materials, cold wort, seed yeast, equipment and pipelines, packaging materials, various utensils and operators, etc. [0003] Therefore, timely disinfection and sterilization of various utensils, production equipment, production environment and packaging materials in the beer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61L2/18A61L2/24A61L9/14B08B3/02A47K7/04

Inventor 张敦杰孔祥兵

Owner BEIJING GRET RESOURCES ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com