Purification process for acid oxidation and alkaline reduction of waste gas containing nitrogen oxide

A technology for nitrogen oxides and exhaust gas, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of low removal rate of nitrogen oxides and low oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1) Exhaust gas conditions

[0031] 40,000 cubic meters per hour, temperature ~ 100°C, normal pressure

[0032] Nitrogen oxides: 1300ppM, Dust: 30~50mg / m3

[0033] 2) Oxidant solution: mass percent concentration > 30% dilute nitric acid

[0034] 3) Alkaline reducing agent solution: sodium hydroxide / sodium sulfide with a mass percentage concentration of 5-10%, wherein the mass ratio of alkali: reducing agent=1-1.5; the cost is 150-300 yuan / ton of reducing solution

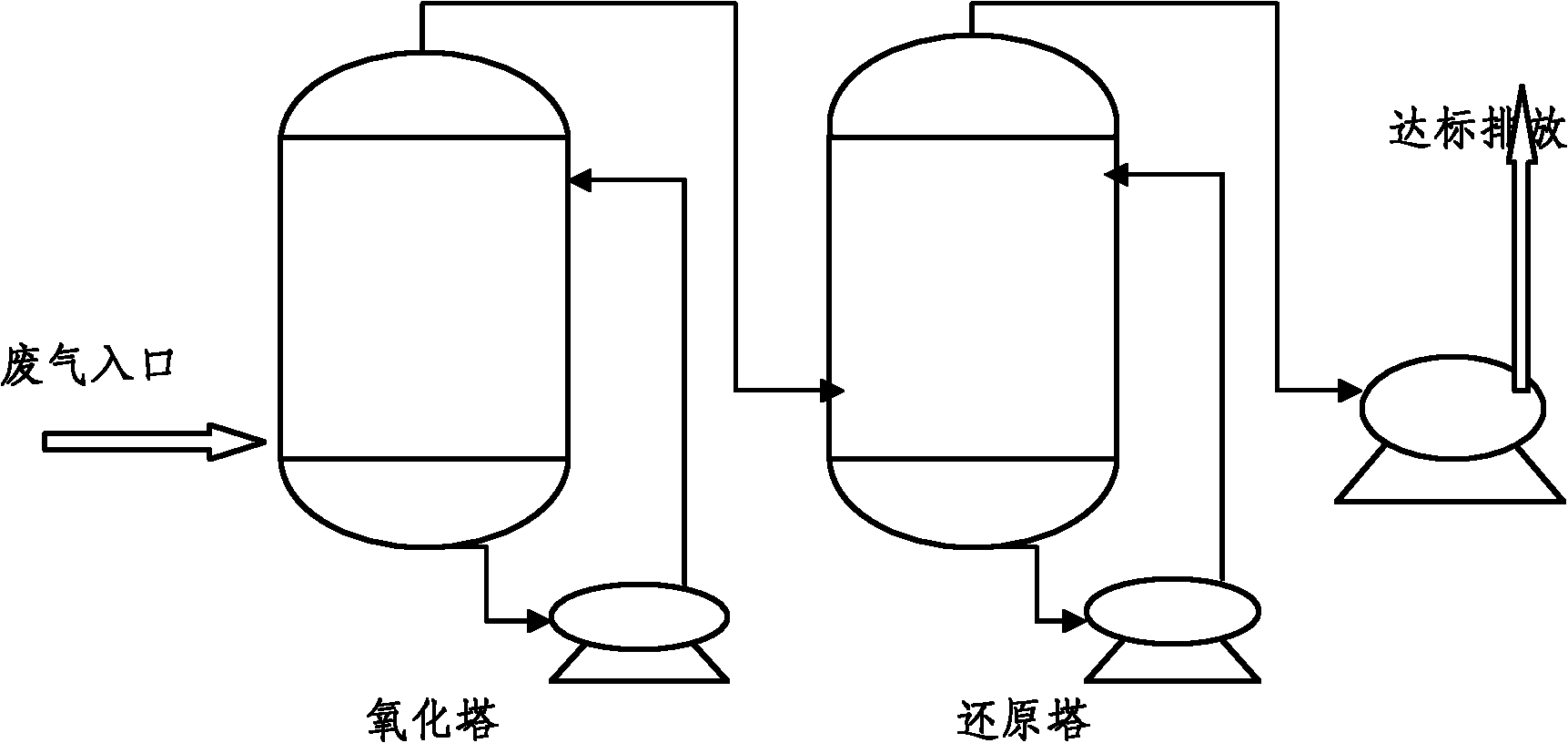

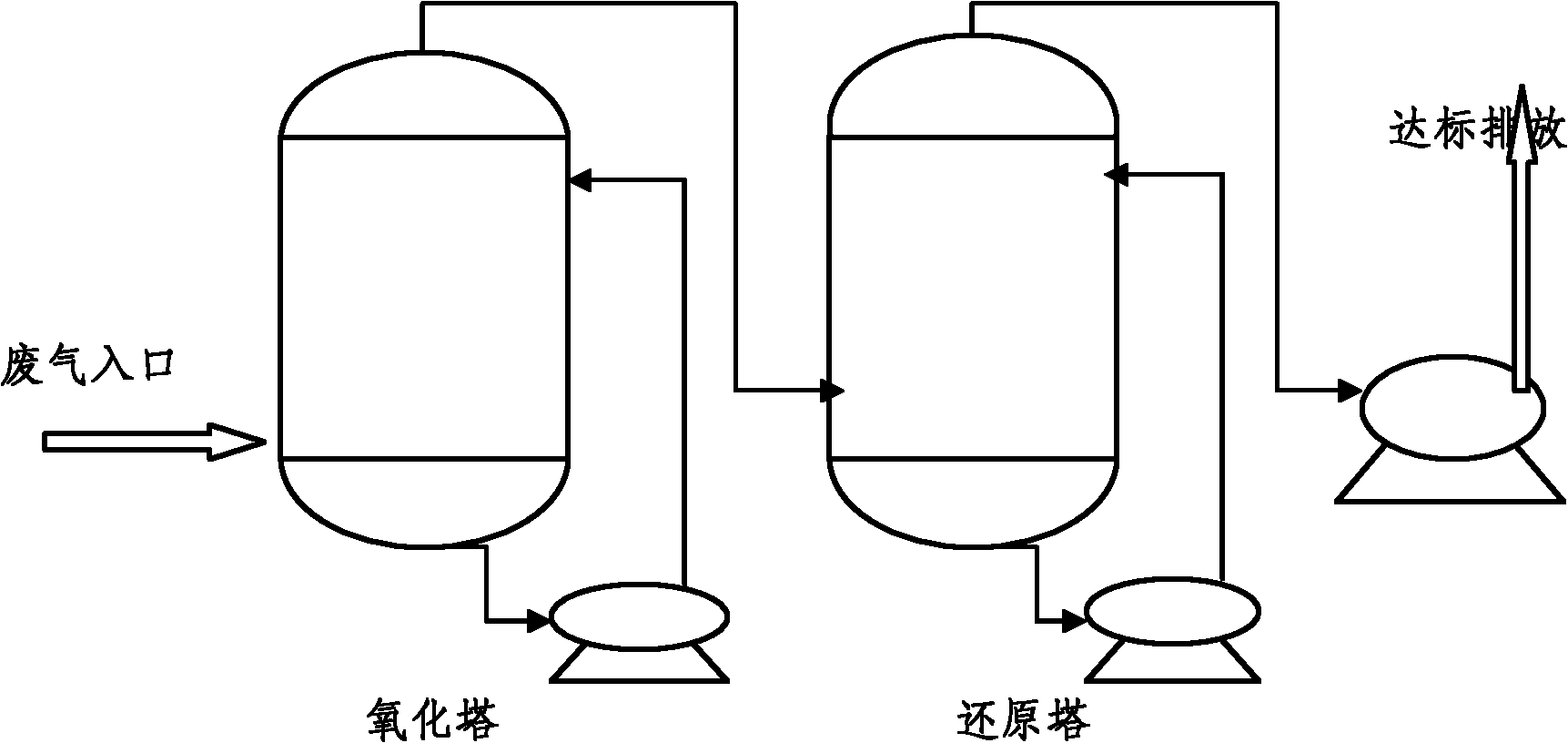

[0035] 4) Process flow

[0036] Under the suction of the tail gas fan, the exhaust gas containing nitrogen oxides enters the oxidation tower from the bottom of the oxidation tower. The exhaust gas first passes through the two-stage flow-through trays, and contacts with the acidic oxidant solution for heat exchange, washing and dust removal. At the same time, the exhaust gas intake is evenly distributed, and the nitric oxide in the exhaust gas is oxidized through the liquid layer of the acidic oxidant solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com