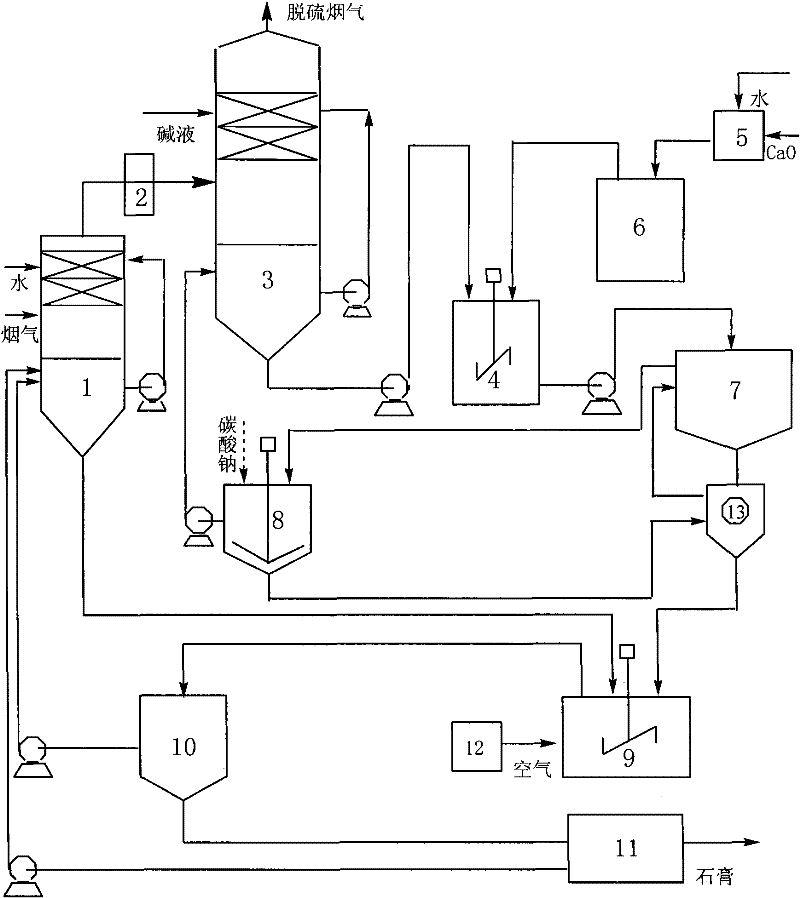

A double-alkali flue gas desulfurization process

A desulfurization process and double-alkali technology, which is applied in the field of double-alkali flue gas desulfurization technology, can solve the problems of large area occupied by regeneration tanks and clarifiers, reduced stability, increased operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The imported flue gas volume is 100000Nm 3 / h (standard cubic meter / hour), flue gas temperature is 100°C, SO 2 The concentration is 1500mg / m 3 , the flue gas enters the water absorption tower, and the liquid-gas ratio of the water absorption tower is controlled at 2L / m 3 , the pH value of the outlet solution is controlled at 2.5. The flue gas enters the alkali absorption tower (using caustic soda solution as the absorbent) from the water absorption tower, and the liquid-gas ratio of the alkali absorption tower is controlled at 2L / m 3 , the pH value of the outlet desulfurization liquid is controlled at 7.0, and the sodium salt content is controlled at 10%. SO in flue gas at the outlet of alkali absorption tower 2 The concentration is 40mg / m 3 .

[0047] The desulfurization liquid enters the regeneration system, the lime milk concentration is controlled at 12%, the stirring speed in the regeneration tank is 200rpm, the regeneration reaction time is controlled at 1.5...

Embodiment 2

[0050] The imported flue gas volume is 150000Nm 3 / h, flue gas temperature is 100℃, SO 2 The concentration is 2000mg / m 3 , the flue gas enters the water absorption tower, and the liquid-gas ratio of the water absorption tower is controlled at 3L / m 3 , the pH value of the outlet solution is controlled at 2.5. The flue gas enters the alkali absorption tower (using caustic soda solution as the absorbent) from the water absorption tower, and the liquid-gas ratio of the alkali absorption tower is controlled at 3L / m 3 , the pH value of the outlet desulfurization liquid is controlled at 6.5, and the sodium salt content is controlled at 12%. SO in flue gas at the outlet of alkali absorption tower 2 The concentration is 100mg / m 3 .

[0051] The desulfurization liquid enters the regeneration system, the concentration of milk of lime is controlled at 8%, the stirring speed in the regeneration tank is 200rpm, the regeneration reaction is controlled at 1h, and the regeneration liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com