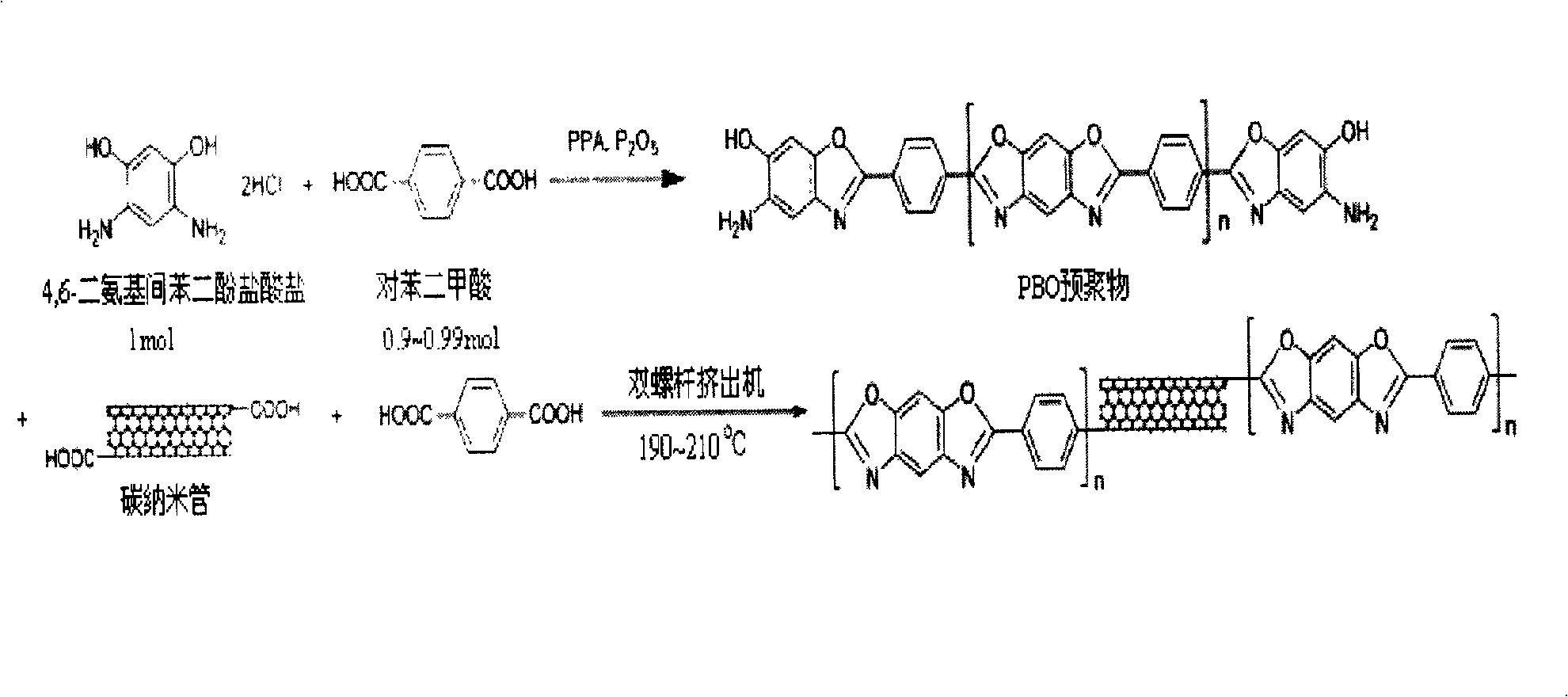

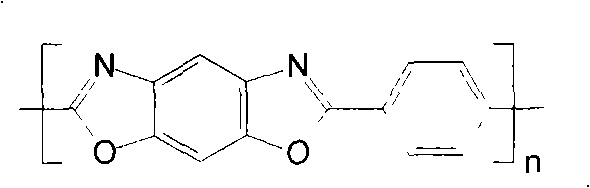

Method for preparing poly(p-phenylene) benzo dioxazole composite fiber containing carbon nano tube

A technology of phenylene benzene and composite fibers, which is applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, wet spinning, etc., and can solve problems such as molecular weight growth, low interfacial bonding force, and limited polymer reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The carbon nanotube raw material was put into 65% concentrated nitric acid solution, ultrasonicated at room temperature for 30 minutes, heated to reflux for 24 hours, diluted with deionized water, and vacuum-filtered with a polycarbonate filter membrane. The filtered solid was continuously washed with deionized water until the pH value of the filtrate was 7. Then the obtained black solid was vacuum-dried at 40° C. for 24 h to obtain the treated MWNTs.

[0030] The prepolymer A solution, 10wt% TPA / PPA suspension and 2.5wt% MWNTs / PA suspension are pumped into a twin-screw extruder with an aspect ratio of 40 and an inner diameter of 20mm with a metering pump, and the flow rate of the metering pump is controlled. The rotation speed is such that the delivery rate of the prepolymer is 60 g / min, while the delivery rate of the TPA / PPA suspension is 1.8 g / min, and the delivery rate of the MWNTs / PA suspension is 17.6 g / min. The shear force in the extruder is 500S -1 , the tempe...

Embodiment 2

[0032]Distribute the prepolymer A solution, 15wt% TPA / PPA suspension and 3wt% MWNTs / PA suspension with a metering pump into a twin-screw extruder with an aspect ratio of 40 and an inner diameter of 20mm, and control the speed of the metering pump , the delivery rate of the prepolymer is 60g / min, while the delivery rate of the TPA / PPA suspension is 1.2g / min, and the delivery rate of the MWNTs / PA suspension is 30g / min. The shear force in the extruder is 500S -1 , the temperature is between 190 and 210°C, and the residence time is about 30 minutes. After passing through the metering pump, the material was spun by dry jet-wet spinning to obtain fibers with an average diameter of 28 μm, a tensile strength of 3.7 GPa, and a tensile modulus of 101 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com