Refining method for glyoxalic acid

A refining method and glyoxylic acid technology are applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as poor quality of glyoxylic acid products, achieve low production cost, improve product quality, The effect of promoting development and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

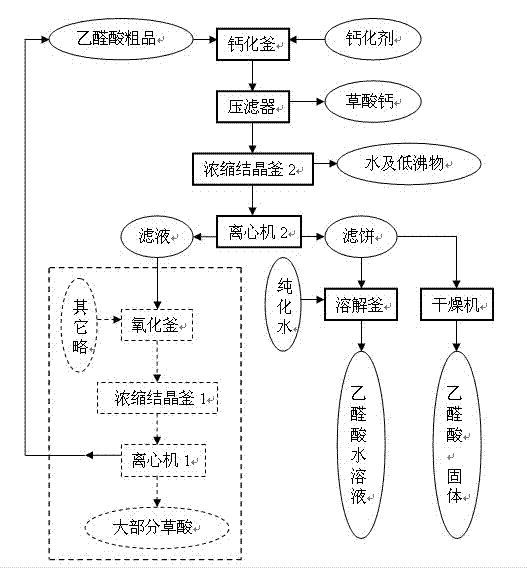

Image

Examples

Embodiment 1

[0038] (1) Calcification and removal of oxalic acid impurities

[0039] Sampling and inspection of 50% of the crude product of glyoxylic acid is then put into the calcification kettle, under vigorous stirring, the temperature is controlled at about 25°C, and then calcium carbonate is added. than CaCO 3 : Oxalic acid=0.98:1, react at room temperature for 0.5 hours, then raise the temperature to 80°C and keep the temperature for 2 hours, cool down to 10°C, press filter, the filtrate enters the concentrated crystallization kettle, and discard the filter cake after pressing dry.

[0040] (2) Concentration under reduced pressure to remove residual nitric acid, HCl and other low-boiling impurities

[0041] Transfer the filtrate obtained from the pressure filtration in the previous process into a concentrated crystallization kettle, heat up and concentrate under reduced pressure, control the temperature rise rate in the kettle to 30°C / h, control the vacuum degree in the kettle to 10...

Embodiment 2

[0049] (1) Calcification and removal of oxalic acid impurities

[0050] Sampling and inspection of 50% of the crude product of glyoxylic acid, then putting it into the calcification kettle, stirring vigorously, controlling the temperature at about 20°C, and then putting in calcium hydroxide. The molar ratio of Ca(OH) 2 : Oxalic acid=0.99:1, after casting, react at room temperature for 0.5 hours, then raise the temperature to 75-77°C and keep it warm for 1.5 hours, cool down to 8°C, press filter, and the filtrate enters the concentrated crystallization kettle, and the filter cake is pressed dry and discarded.

[0051] (2) Concentration under reduced pressure to remove residual nitric acid, HCl and other low-boiling impurities

[0052] Transfer the filtrate obtained by pressure filtration from the previous process to a concentrated crystallization kettle, heat up and concentrate under reduced pressure. When the inner solution is concentrated to a concentration of 78.5%, the co...

Embodiment 3

[0060] (1) Calcification and removal of oxalic acid impurities

[0061] Sampling and inspection of 50% of the crude product of glyoxylic acid, then put it into the calcification kettle, under vigorous stirring, control the temperature at about 18°C, put in calcium oxide within 1 hour, the time of adding calcium oxide is 1 hour, and its The molar ratio of oxalic acid is calcium oxide: oxalic acid=0.97:1. After casting, react at room temperature for 0.5 hours, then raise the temperature to 67-69°C and keep it warm for 2.5 hours, cool down to 7°C, press filter, and the filtrate enters the concentrated crystallization kettle, filters Discard the biscuits when they are dry.

[0062] (2) Concentration under reduced pressure to remove residual nitric acid, HCl and other low-boiling impurities

[0063] Transfer the filtrate obtained from the pressure filtration in the previous process into a concentrated crystallization kettle, heat up and concentrate under reduced pressure, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com