Preparing method for MoS2-CNT multi-level nano-structure electrolysis water hydrogen production material

A technology of nanostructure and electrolysis of water, which is applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc., can solve problems such as poor electrical conductivity, limited electron transport rate, catalytic performance barrier, etc., achieve rapid conduction, increase contact area, enhance the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

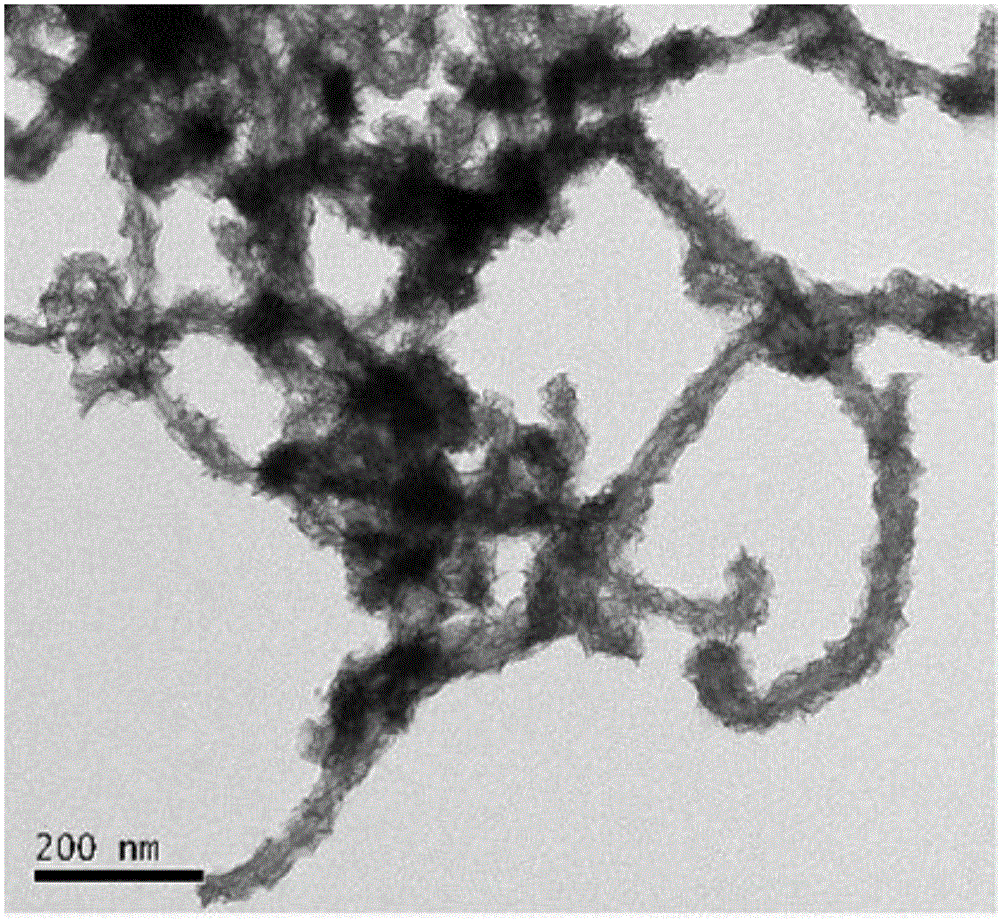

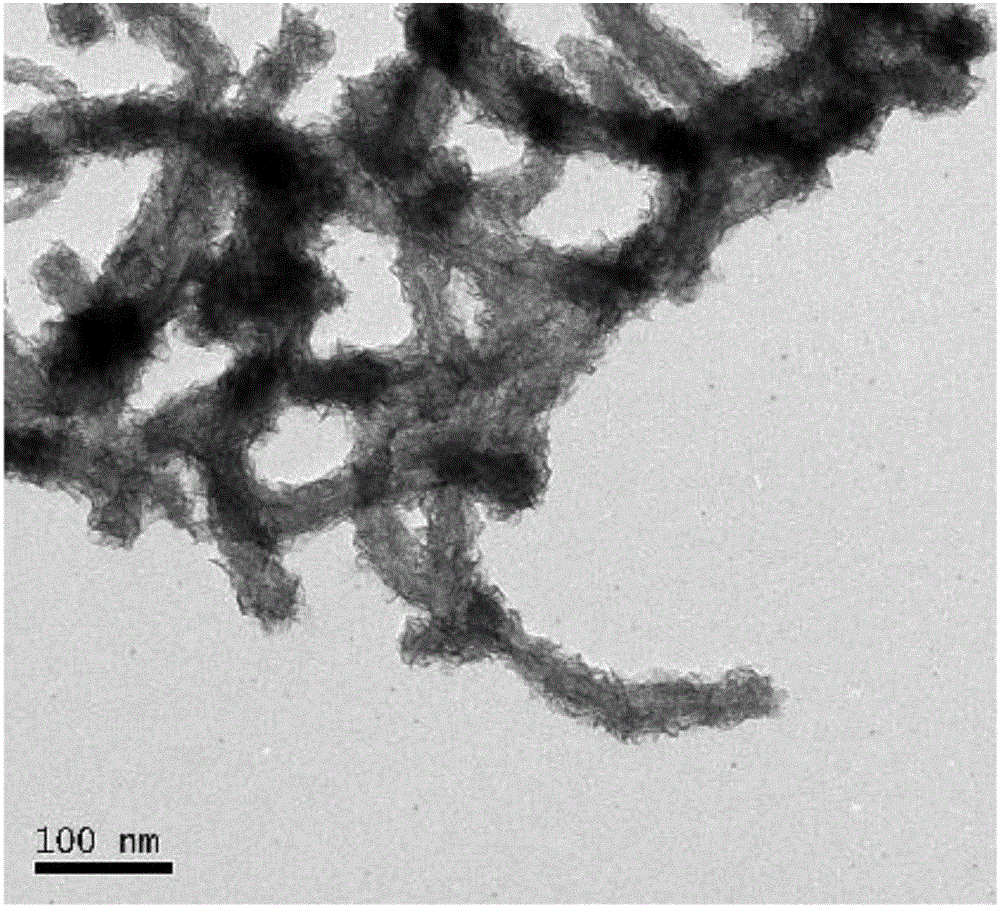

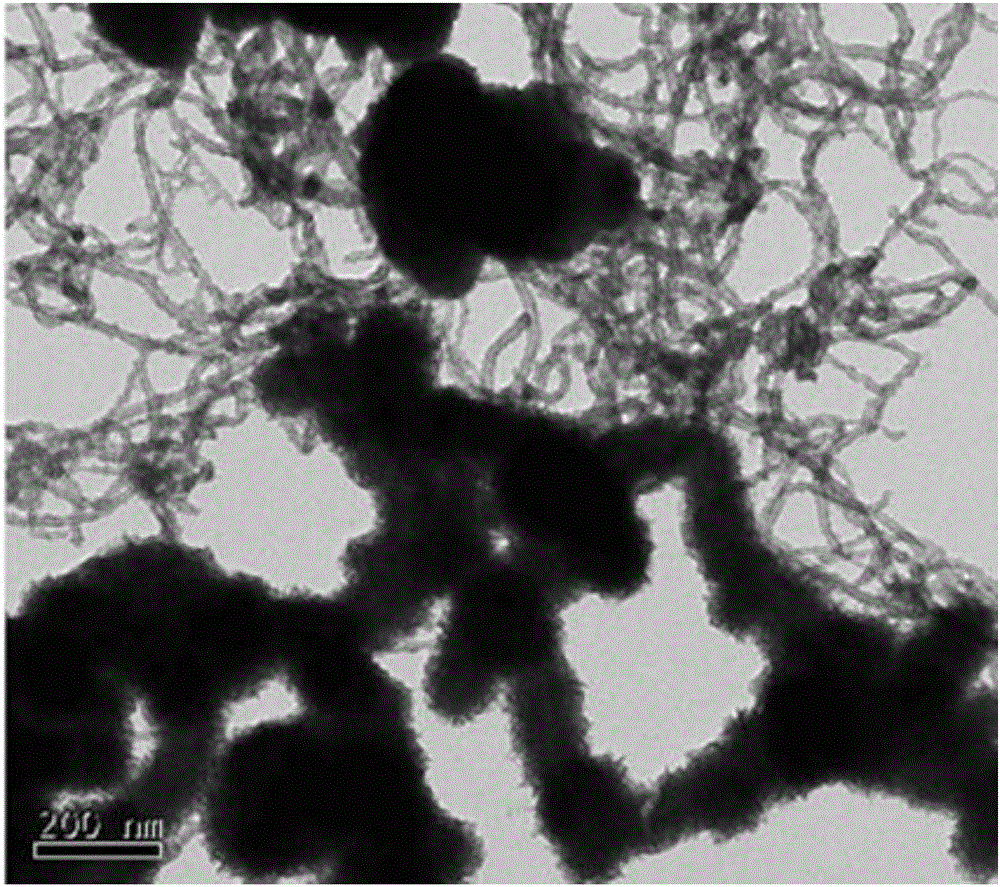

[0028] A kind of MoS 2 -The preparation method of the CNT multilevel nanostructure electrolysis water hydrogen production material, comprising the following steps:

[0029] 1) Functionalization of multi-walled carbon nanotubes: acid oxidation treatment of carbon nanotubes to obtain functionalized carbon nanotubes;

[0030] 2) MoS 2 - Preparation of CNT: After mixing and dispersing alcohol-water mixed solvent and functionalized carbon nanotubes, adding ammonium molybdate and thiourea to react, and obtaining the product after separation and washing.

[0031] Preferably, in step 1), the acid oxidation treatment is to mix carbon nanotubes with acid, then add an oxidant to react, and obtain functionalized carbon nanotubes after washing, dispersing and drying.

[0032] Preferably, in step 1), the acid is one of concentrated sulfuric acid or a mixed acid composed of concentrated sulfuric acid and concentrated nitric acid in a volume ratio (1~3): 1; further preferably, in step 1), t...

Embodiment 1

[0049] Example 1 (MoS 2 - Preparation of CNT-60):

[0050] Functionalization of multi-walled carbon nanotubes: 1 g of carbon nanotubes (Flotube 9110, CNano, diameter 10-15 nm, the same below) and 23 mL of concentrated sulfuric acid were added to a 250 mL Erlenmeyer flask, and stirred overnight at room temperature. Subsequently, place in a water bath and heat to 40 °C, add 200 mg NaNO 3 , and stirred for 5 minutes to completely dissolve it. Add 1g KMnO 4 , and keep the reaction temperature below 45°C, and stir for 30min. Then 3 mL of water was added, after 5 min, another 3 mL was added, and after another 5 min, 40 mL of water was added. After 15 min, remove the Erlenmeyer flask from the water bath, and add 140 mL of water and 10 mL of 30% H 2 o 2 . After stirring at room temperature for 5 min, the reaction product was repeatedly washed with 5 wt% hydrochloric acid and distilled water, dispersed in 10 mL of water, and freeze-dried to obtain about 1 g of functionalized car...

Embodiment 2

[0052] Example 2 (MoS 2 - Preparation of CNT-70):

[0053] Functionalization of multi-walled carbon nanotubes: Add 1 g of carbon nanotubes and 23 mL of concentrated sulfuric acid into a 250 mL Erlenmeyer flask, and stir overnight at room temperature. Subsequently, place in a water bath and heat to 40 °C, add 200 mg NaNO 3 , and stirred for 5 minutes to completely dissolve it. Add 1g KMnO 4 , and keep the reaction temperature below 45°C, and stir for 30min. Then 3 mL of water was added, after 5 min, another 3 mL was added, and after another 5 min, 40 mL of water was added. After 15 min, remove the Erlenmeyer flask from the water bath, and add 140 mL of water and 10 mL of 30% H 2 o 2 . After stirring at room temperature for 5 min, the reaction product was repeatedly washed with 5 wt% hydrochloric acid and distilled water, dispersed in 10 mL of water, and freeze-dried to obtain about 1 g of functionalized carbon nanotubes.

[0054] MoS 2 - Preparation of CNT: Add 30 mg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com