Disperse dye composition, and preparation method and application thereof

A technology for disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve problems such as unsatisfactory environmental protection results, losses in printing and dyeing plants, and different content of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

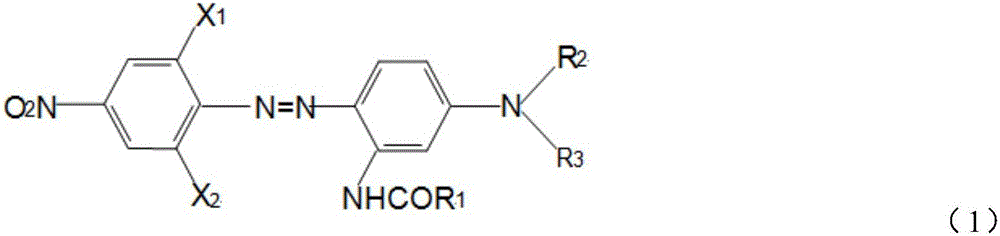

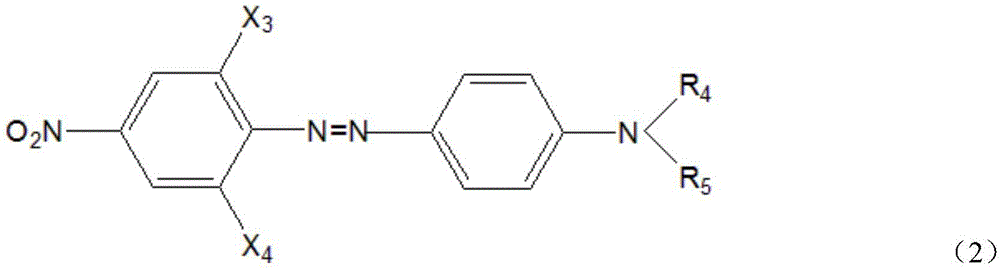

Method used

Image

Examples

preparation example 1

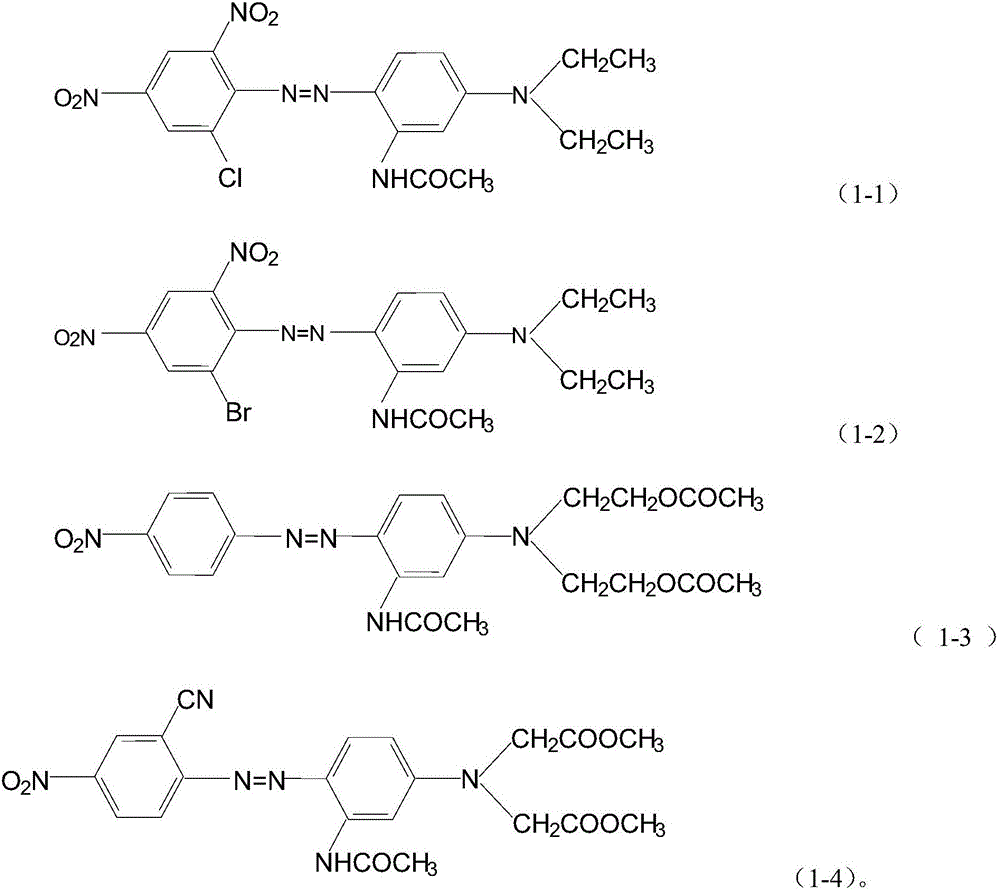

[0102] a) Add the intermediate 2,4-dinitro-6-chloroaniline into water for beating, add 30% sodium hydroxide solution, adjust the pH to 11, raise the temperature to 60° C., keep it warm for 30 minutes, filter, wash with water, and dry;

[0103] b) Add sulfuric acid to the diazo kettle, start stirring, then slowly add nitrosyl sulfuric acid, control the temperature not to exceed 40°C, after the addition is complete, cool down to 20°C, slowly and evenly add the 2,4- After the addition of dinitro-6-chloroaniline, the diazotization reaction was carried out at 25-30°C for 6 hours to obtain the diazo component, which was then used;

[0104] c) Add water, sulfuric acid, and Pingping to the coupling kettle, add the coupling component N,N-diethyl-m-acetaniline, stir for 30 minutes, add ice and isooctyl alcohol, control the temperature below 10°C, and add dropwise The diazo component to be used is added dropwise for about 5 hours. After the addition is complete, the temperature is contro...

preparation example 2

[0106] According to the same method of Preparation Example 1, the difference is that the intermediate 2,4-dinitro-6-chloroaniline in Preparation Example 1 is replaced by 2,4-dinitro-6-bromoaniline to prepare The product (I-2) is obtained. The resulting product (I-2) contains the structure of formula (1-2) as component A.

preparation example 3

[0108] a) Add sulfuric acid to the diazo kettle, start stirring, then slowly add nitrosyl sulfuric acid, control the temperature not to exceed 40°C, after the addition, cool down to 10°C, slowly and evenly add the intermediate p-nitroaniline for about 3 hours, Add complete, keep warm for 2.5 hours, obtain diazo component, stand-by;

[0109] b) Add water and ice to the diazo dilution kettle, cool down to below 5°C, press into the diazo solution for dilution, control the dilution temperature to be no more than 5°C, after pressing, add activated carbon, stir for 30 minutes, filter, Put the diazo filtrate into the coupling kettle;

[0110] c) After the diazo filtrate is poured in, the coupling kettle is started to stir, urea is added, Pingping is added, the coupling component N, N-diacetoxyethyl m-acetaniline is added, and the acidity of the coupling material is adjusted to 10% (acidity of sulfuric acid), Control the reaction temperature at 15-25°C, keep it warm for 4 hours, slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com