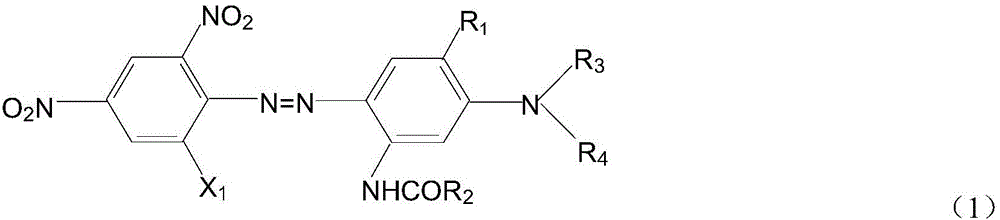

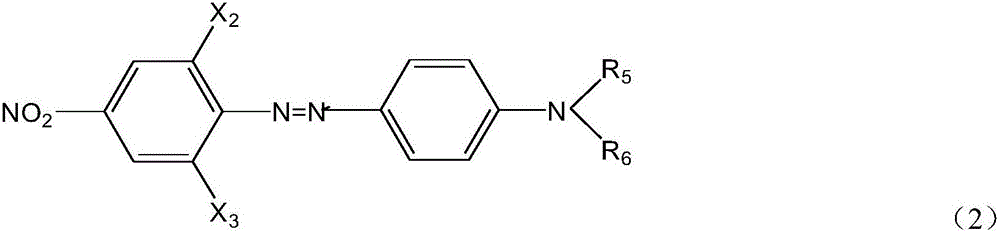

Disperse dye composition as well as preparation method and application thereof

A technology of disperse dyes and compositions, applied in dyeing methods, azo dyes, organic dyes, etc., which can solve the problems of different contents of harmful substances, the impact of sewage from printing and dyeing factories on the ecological environment, and high levels of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

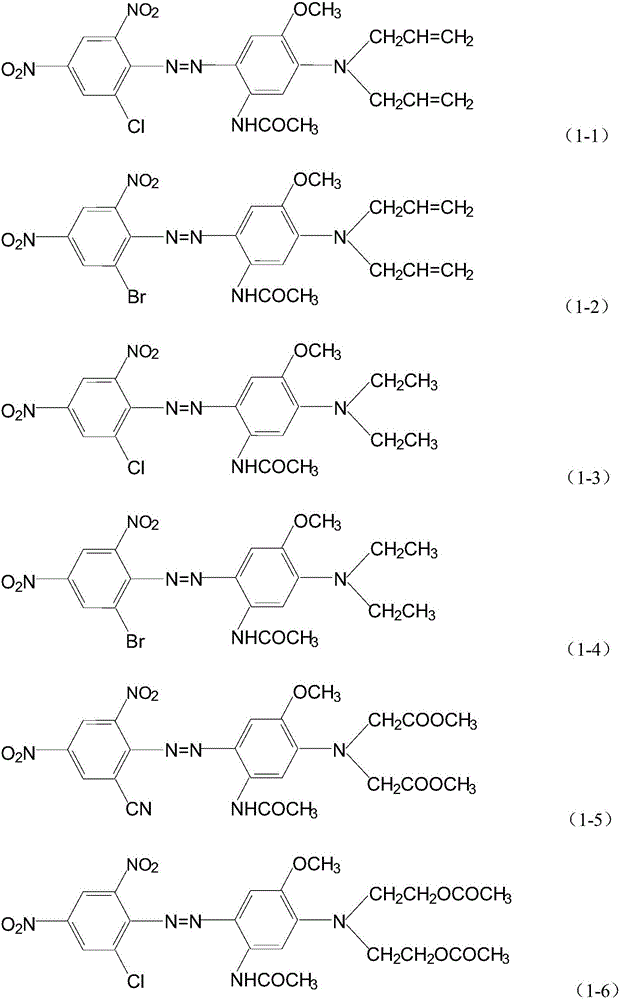

preparation example 1

[0084] a) Add the intermediate 2,4-dinitro-6-chloroaniline into water for beating, add 30% sodium hydroxide solution, adjust the pH to 11, raise the temperature to 60° C., keep it warm for 30 minutes, filter, wash with water, and dry;

[0085] b) Add sulfuric acid to the diazo kettle, start stirring, then slowly add nitrosyl sulfuric acid, control the temperature not to exceed 40°C, after the addition is complete, cool down to 20°C, slowly and evenly add the 2,4- After the addition of dinitro-6-chloroaniline, heat the diazotization reaction at 25-30°C for 6 hours to obtain the diazo component, which is ready for use;

[0086] c) Add water, sulfuric acid and flatten to the coupling kettle, add the coupling component N,N-diallyl-2-methoxy-5-acetamidoaniline, stir for 30 minutes, add ice and isooctyl alcohol, Control the temperature below 10°C, add the diazo component to be used dropwise, the dropwise addition time is about 5 hours, after the addition is completed, control the te...

preparation example 2-4,6-12

[0088] According to the same method as Preparation Example 1, the difference is that the intermediate 2,4-dinitro-6-chloroaniline, coupling component N,N-diethyl-2-methoxy - 5-acetamidoaniline was replaced by the intermediates and coupling components in Table 2 to prepare products (I-2)-(I-4) and (I-6)-(I-12).

[0089] Table 1

[0090] project intermediate Coupling components Preparation example 2 2,4-Dinitro-6-bromoaniline N,N-Diallyl-2-methoxy-5-acetamidoaniline Preparation example 3 2,4-Dinitro-6-chloroaniline N,N-Diethyl-2-methoxy-5-acetamidoaniline Preparation Example 4 2,4-Dinitro-6-bromoaniline N,N-Diethyl-2-methoxy-5-acetamidoaniline Preparation Example 6 2,4-Dinitro-6-chloroaniline N,N-Diacetoxyethyl-2-methoxy-5-acetamidoaniline Preparation Example 7 2,4-Dinitro-6-bromoaniline N,N-Diacetoxyethyl-2-methoxy-5-acetamidoaniline Preparation example 8 2,4-Dinitro-6-chloroaniline N-allyl-N-acetoxyethyl-2-etho...

preparation example 5

[0092] According to the same method as Preparation Example 1, the difference is that the intermediate 2,4-dinitro-6-chloroaniline, coupling component N,N-diethyl-2-methoxy -5-Acetamidoaniline is replaced by intermediate 2,4-dinitro-6-bromoaniline and coupling component N,N-diacetoxymethyl-2-methoxy-5-acetamidoaniline, Prepare the raw material filter cake; then carry out cyanidation: add DMF to the cyanidation kettle, raise the temperature to 80°C, add ketone cyanide and sodium cyanide, raise the temperature to 100°C and keep it for 1 hour, cool down to 80-85°C, and put in The raw material filter cake is heated up to 100-110°C, kept warm for 3 hours, taking a sample to measure the reaction end point, cooling down to 25°C after passing the test, filtering and washing with water to obtain a cyanide filter cake; then removing ketones and cyanide: mix water, hydrochloric acid 1. The ferric chloride of ferric chloride beating is fully dissolved, and the cyanide filter cake is added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com