Texturing method for polysilicon wafer cutting by diamond wire

A technology of diamond wire cutting and polycrystalline silicon wafers, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of accumulation of precious metal content, increase of investment in waste liquid treatment, increase of process complexity, etc., and achieve cost-saving The effect of shortening the overall time of cashmere, saving consumption, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

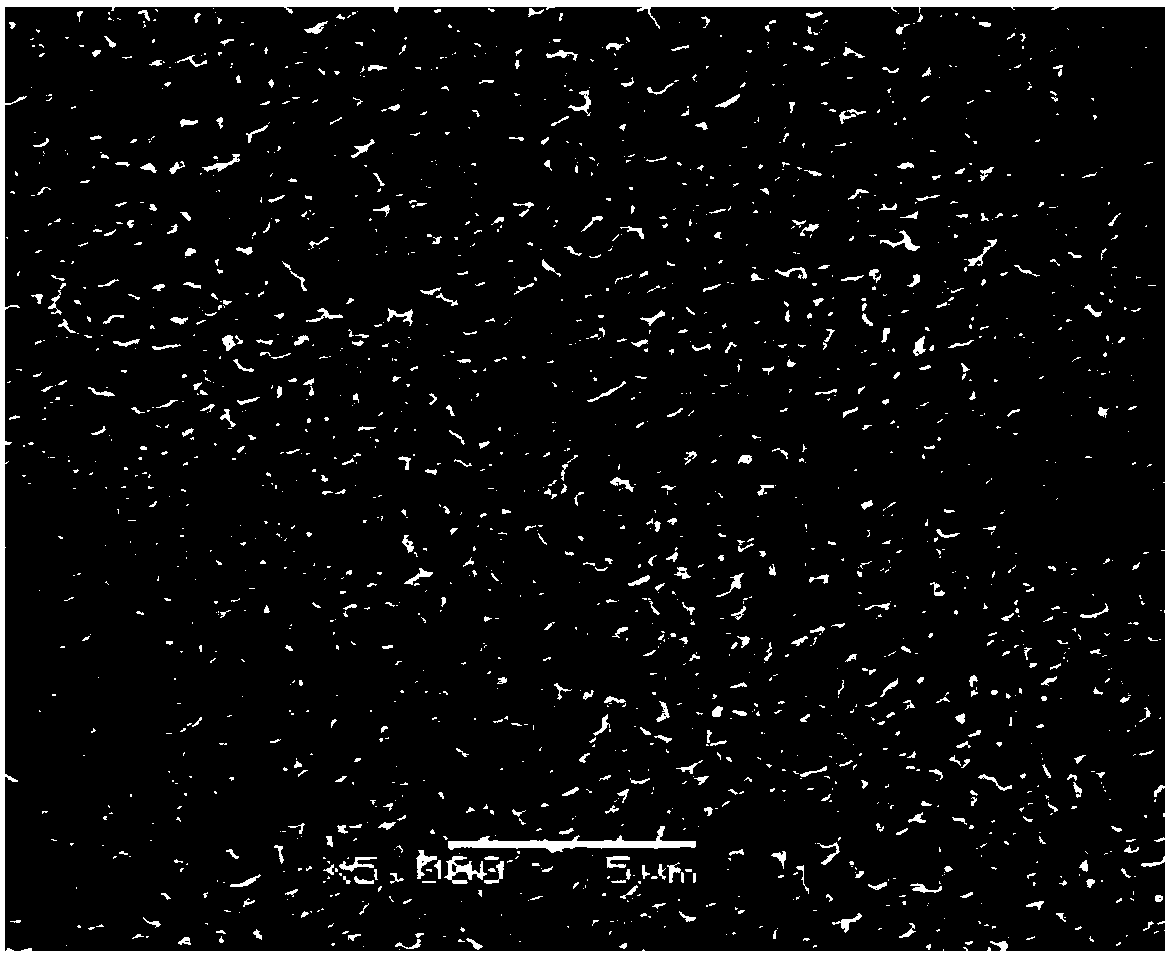

[0083] In this embodiment, a diamond wire cut polycrystalline P-type 156 silicon wafer is used as the base material, and texturing is performed as follows:

[0084] Step 1: Configure an etching solution, immerse the diamond wire-cut polysilicon wafer in the etching solution, and react at 40°C for 6 minutes to promote the formation of a porous structure on the surface of the silicon wafer;

[0085] Among them, the corrosive solution includes mixed aqueous solution and fluoride salt, the fluoride salt is sodium fluoride, potassium fluoride or ammonium fluoride, and the mass ratio of the fluoride salt to the mixed aqueous solution is 5:100;

[0086] The mixed aqueous solution includes the following substances in volume fractions: 1% metal ion-containing additive, 6% hydrofluoric acid volume fraction, 20% hydrogen peroxide volume fraction, and the balance is deionized water;

[0087] Metal ion-containing additives include silver nitrate and organic solution, and control the amount ratio of...

Embodiment 2

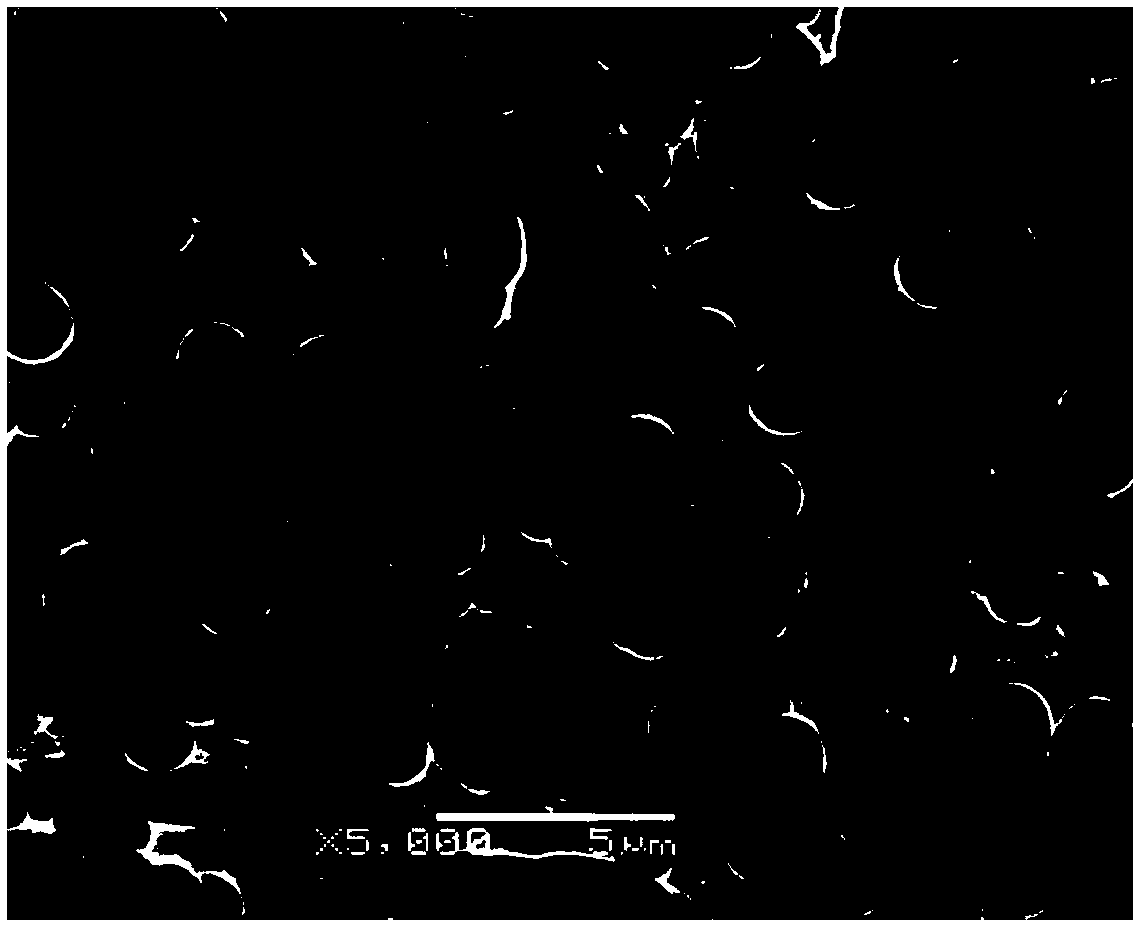

[0120] In this embodiment, a diamond wire cut polycrystalline P-type 156 silicon wafer is used as the base material, and texturing is performed as follows:

[0121] Step 1: Configure an etching solution, immerse the diamond wire cut polycrystalline silicon wafer in the etching solution, and react at 20°C for 15 minutes to promote the formation of a porous structure on the surface of the silicon wafer;

[0122] Among them, the corrosive solution includes mixed aqueous solution and fluoride salt, the fluoride salt is sodium fluoride, potassium fluoride or ammonium fluoride, and the mass ratio of the fluoride salt to the mixed aqueous solution is 0.1:100;

[0123] The mixed aqueous solution includes the following substances in volume fractions: 3% of metal ion-containing additives, 5% by volume of hydrofluoric acid, 50% by volume of hydrogen peroxide, and deionized water as the balance;

[0124] Silver ion-containing additives include silver nitrate and organic solution, and control the a...

Embodiment 3

[0140] In this embodiment, a diamond wire cut polycrystalline P-type 156 silicon wafer is used as the base material, and texturing is performed as follows:

[0141] Step 1: Configure an etching solution, immerse the diamond wire cut polycrystalline silicon wafer in the etching solution, and react at 80°C for 4 minutes to promote the formation of a porous structure on the surface of the silicon wafer;

[0142] Among them, the corrosive solution includes a mixed aqueous solution and a fluoride salt, the fluoride salt is sodium fluoride, potassium fluoride or ammonium fluoride, and the mass ratio of the fluoride salt to the mixed aqueous solution is 8:100;

[0143] The mixed aqueous solution includes the following substances in volume fractions: 0.05% of silver ion-containing additives, 30% of hydrofluoric acid, 10% of hydrogen peroxide, and deionized water as the balance;

[0144] Silver ion-containing additives include silver nitrate and organic solution, and control the amount ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com