Method of circulation utilizing phenol containing waste water in novolac epoxy preparing process

A novolak epoxy resin and waste water recycling technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of ineffective recycling of phenol and high cost of environmental protection treatment, so as to reduce the cost of environmental protection treatment, improve market competitiveness and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

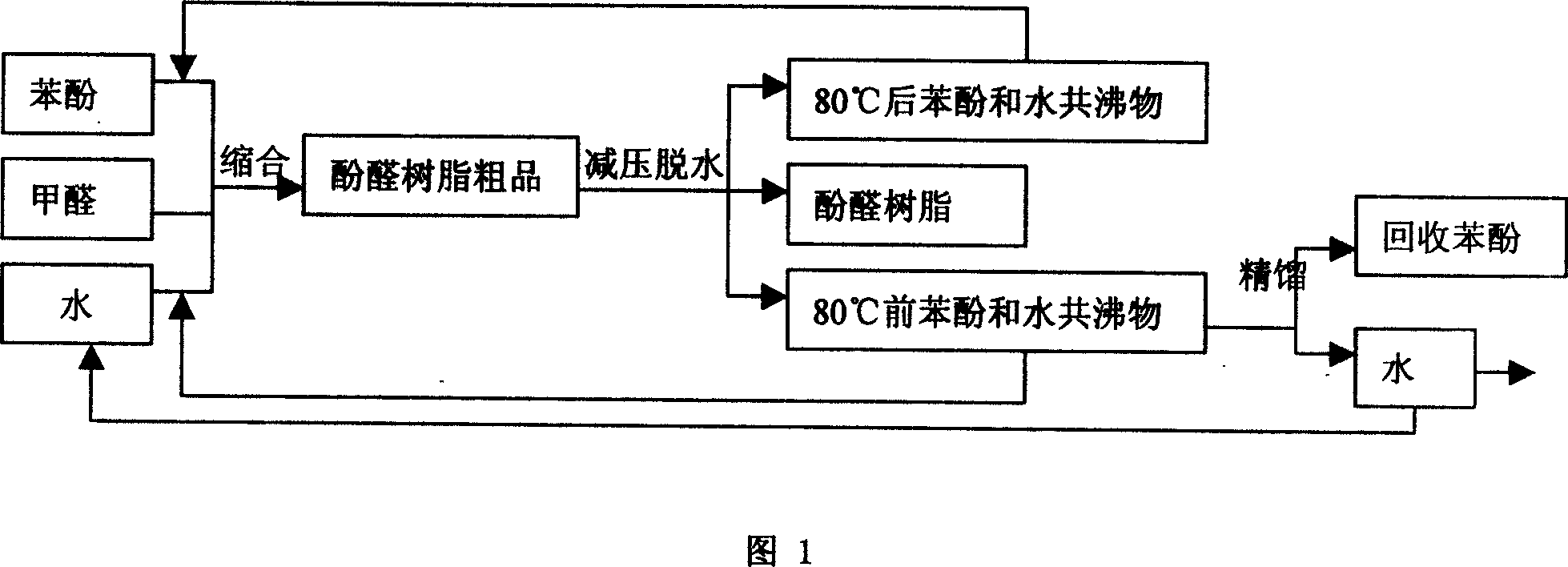

Image

Examples

Embodiment 1

[0015] Add 900 grams of phenol, 320 grams of formaldehyde, and 900 grams of water into the condensation reaction kettle. Under the action of the phenolic condensation catalyst, the condensation reaction is carried out at 85-115°C for 2-4 hours. and phenol until the phenol and water are completely removed to obtain a phenolic resin, and the softening point of the obtained phenolic resin is 53°C. The distilled phenol wastewater, the phenol-water azeotrope before 80°C, which contains about 5% phenol, enters the reaction water storage tank after condensation, and the phenol-water azeotrope after 80°C condenses and enters the recovery phenol storage tank .

Embodiment 2

[0017] 850 grams of phenol, 320 grams of formaldehyde, 950 grams of phenol-water azeotrope before 80°C are added to the condensation reaction kettle, and under the action of the catalyst, the condensation reaction is carried out at 85-115°C for 2-4 hours. Distill under reduced pressure at 0.09MPa to dehydrate and phenol until the phenol and water are completely removed to obtain a phenolic resin. The softening point of the obtained phenolic resin is 54°C. The phenol-water azeotrope before 80°C condenses and enters the reaction water storage tank, and the phenol-water azeotrope after 80°C condenses and enters the recovery phenol storage tank.

Embodiment 3

[0019] 200 grams of phenol, 374 grams of formaldehyde, 1800 grams of phenol-water azeotrope after 80°C are added to the condensation reaction kettle, under the action of the catalyst, the condensation reaction is carried out at 85-115°C for 2-4 hours, and after neutralization, the vacuum degree -0.09 Dehydration and phenol were distilled under reduced pressure under MPa until the phenol and water were completely removed to obtain phenolic resin. The softening point of the obtained phenolic resin was 52°C. The phenol-water azeotrope before 80°C condenses and enters the reaction water storage tank, and the phenol-water azeotrope after 80°C condenses and enters the recovery phenol storage tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com