Water soluble polyether quenching medium

A technology of water-soluble polyether and quenching medium, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of increased viscosity of quenching medium, low quenching cooling speed, and economical decline, and achieve good quenching properties, good Inhibition effect, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare a water-soluble quenching medium with a concentration of 1%. The water-soluble polyether is a condensation product of ethylene oxide and propylene oxide. The dosage is 1%, and the number-average molecular weight Mn is less than 20000; The group contains one -OH, -COOH; the defoamer is non-ionic polyether type, the dosage is 500ppm; the compound fungicide is prepared by triazine and isothiazolinone in a ratio of 1:10, and the dosage is 0.1 %; PH value regulator is potassium hydroxide, consumption is 0.2%; Tap water 97.7%.

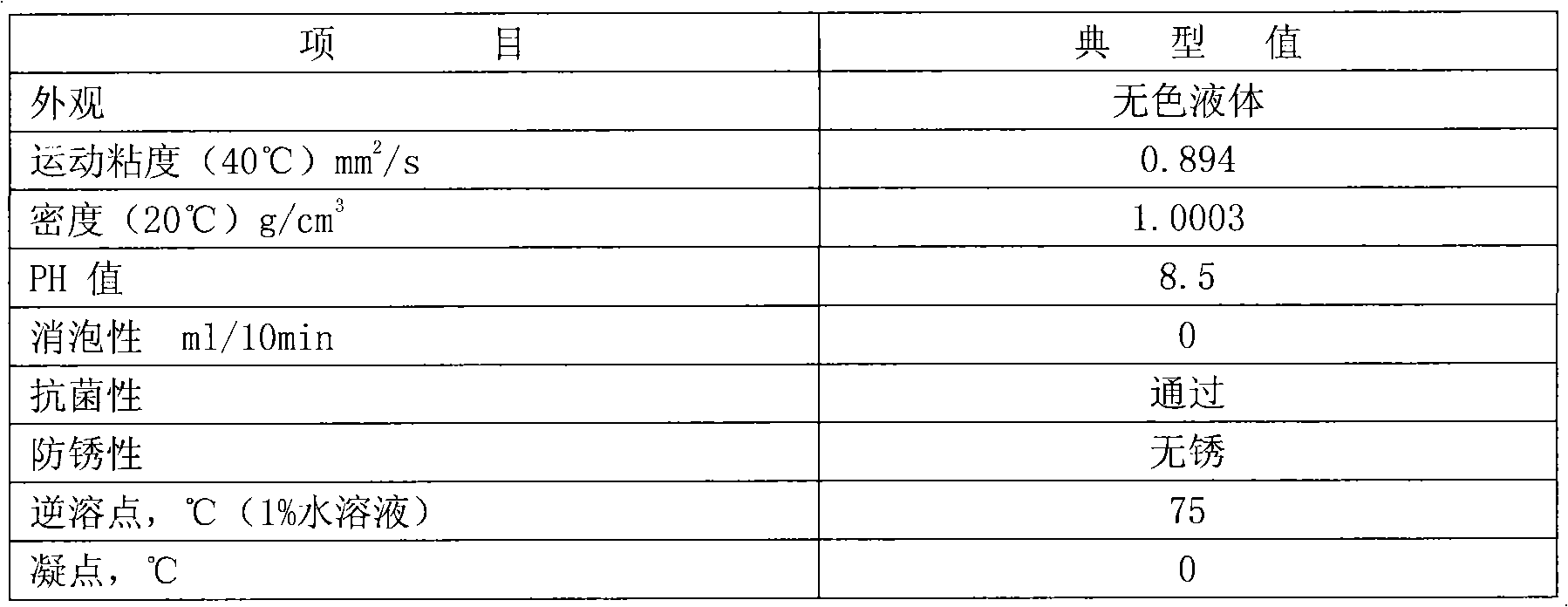

[0018] The properties and cooling characteristics of 1% concentration quenching medium are as follows:

[0019] Properties of Table 11% Concentration Quenching Medium

[0020]

[0021]

[0022] Table 21% concentration quenching medium and water, standard quenching oil cooling speed comparison

[0023] cooling rate

Embodiment 2

[0025] Configure a water-soluble quenching medium with a concentration of 5%. The water-soluble polyether is a condensation product of ethylene oxide and propylene oxide. The dosage is 5%, and the number-average molecular weight Mn is less than 20000; The group contains one -OH, -COOH; the defoamer is silicone type, and the dosage is 100ppm; the compound fungicide is prepared by triazine and isothiazolinone in a ratio of 1:8, and the dosage is 0.3%; PH value regulator is monoethanolamine, consumption is 1%; Tap water 93.2%.

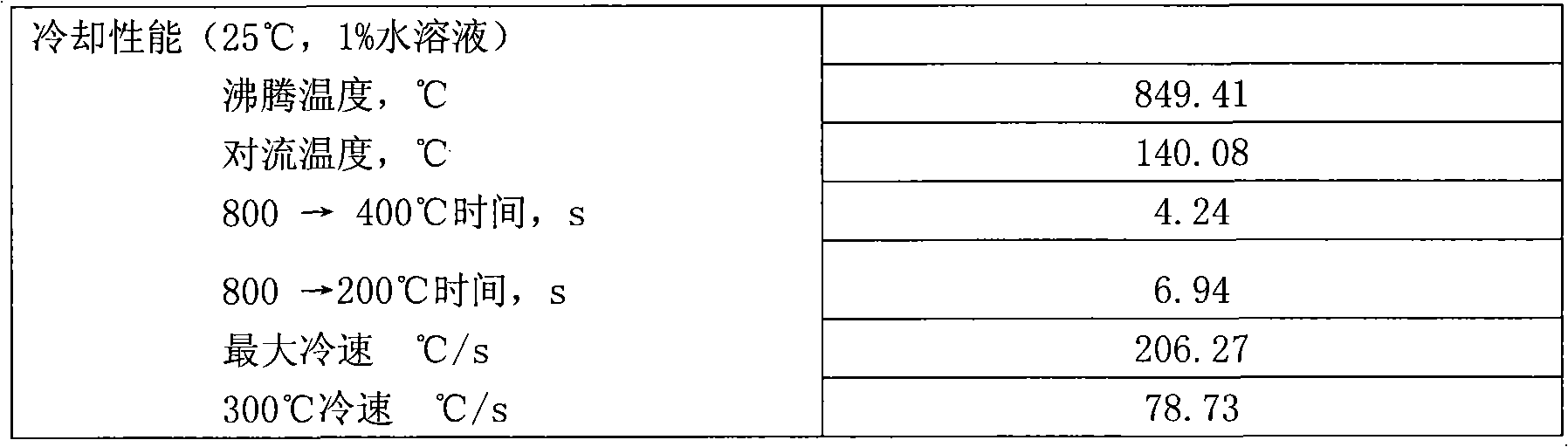

[0026] Table 35% Concentration Quenching Medium Properties

[0027]

[0028]

[0029] Table 45% concentration quenching medium and water, standard quenching oil cooling speed comparison

[0030] cooling rate

Embodiment 3

[0032] Configure 10% concentration of water-soluble quenching medium, water-soluble polyether is the condensation product of ethylene oxide and propylene oxide, the dosage is 10%, the number average molecular weight Mn is less than 20000; water-soluble antirust agent 0.2%, polar The group contains three -COOH; the defoamer is silicone type, and the dosage is 200ppm; the compound fungicide is prepared by triazine and isothiazolone in a ratio of 1:5, and the dosage is 0.5%; the pH value Regulator is diethanolamine, the dosage is 0.8%; deionized water is 88.5%.

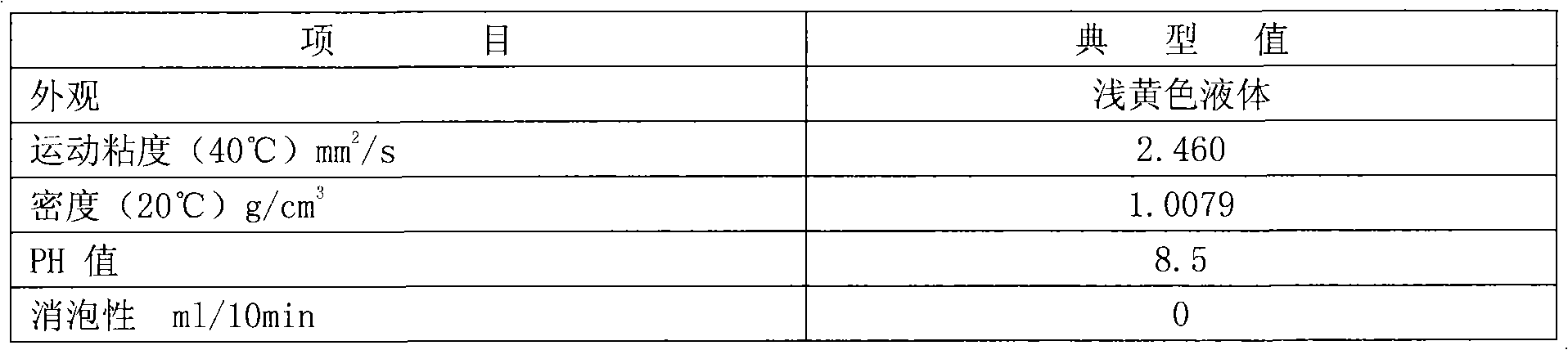

[0033] Table 5 Properties of 10% Concentration Quenching Medium

[0034]

[0035] Table 6 Comparison of cooling speed of 10% concentration quenching medium, water and standard quenching oil

[0036] cooling rate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com