Method for producing ethanolamine

A technology of ethanolamine and ethylene oxide, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve the problems of high reaction pressure of ethylene oxide, low selectivity of ethanolamine and high reaction temperature, Achieve the effect of low reaction temperature, simple regeneration and good acidity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Mix 187 g of silica sol with 200 mL of deionized water, stir at room temperature for 10 minutes, then add 5.6 mL of ethylenediamine to the above mixed solution, and stir at room temperature for 0.5 hours; 2 / Al 2 O 3 =25 (molar ratio) ratio is called Al 2 (SO 4 ) 3 .18H 2 O, added to the above mixed solution, and vigorously stirred for 0.5 hours, a white viscous colloid will be obtained. Add 8g of NaOH to the colloid, adjust the pH of the system to 13-14, continue to stir for 1 hour, then transfer to the crystallization kettle, and keep it at 180°C for 36 hours. The crystallized product was washed with deionized water and dried at 100°C. The molecular sieve obtained after drying was placed in a muffle furnace and calcined in an air atmosphere with an air flow rate of 100 ml / min and a temperature of 15 The temperature was raised to 600°C at a rate of °C / min, and calcined at this temperature for 6 hours, thereby obtaining a molecular sieve precursor I. After placing the mo...

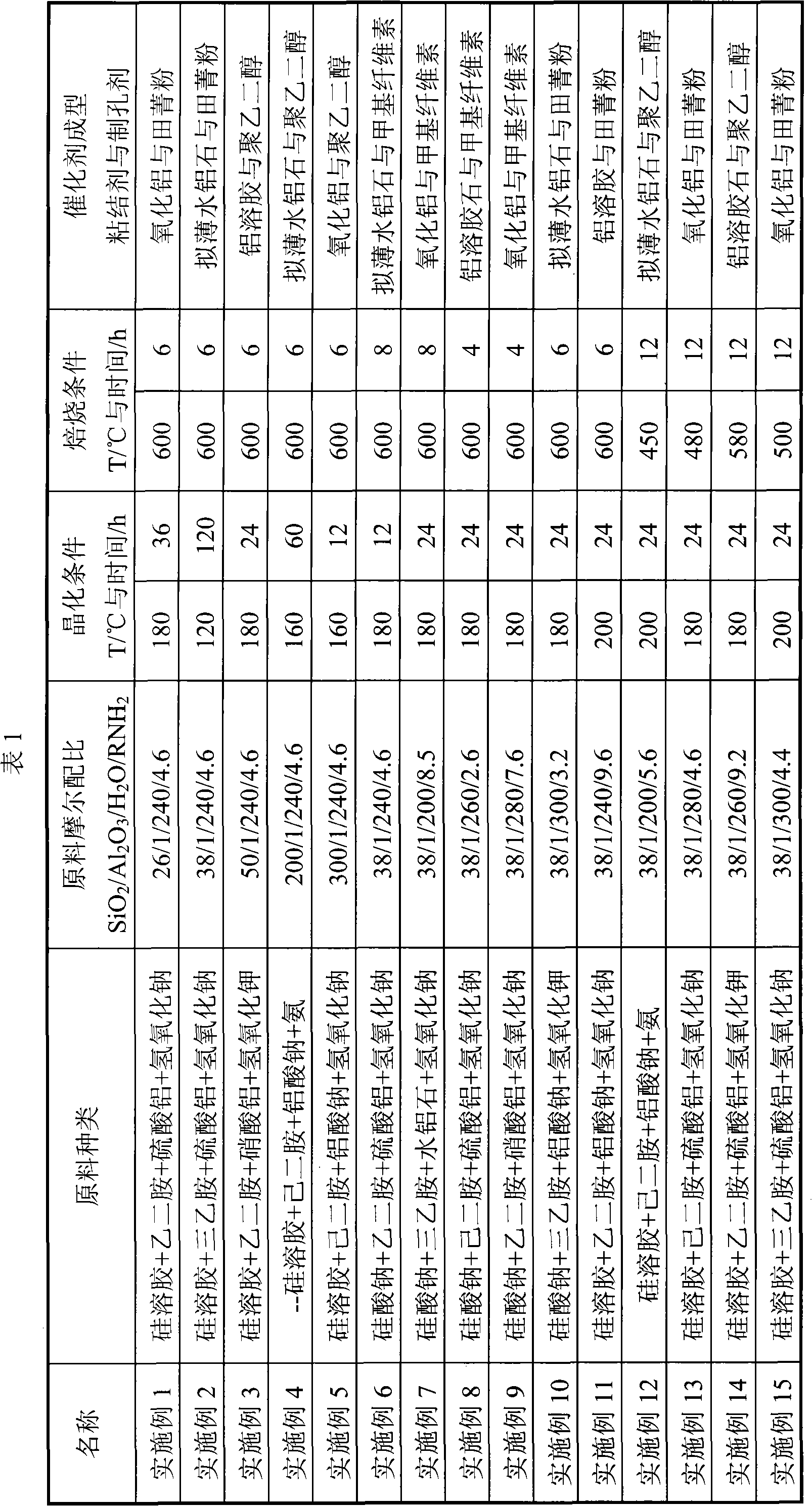

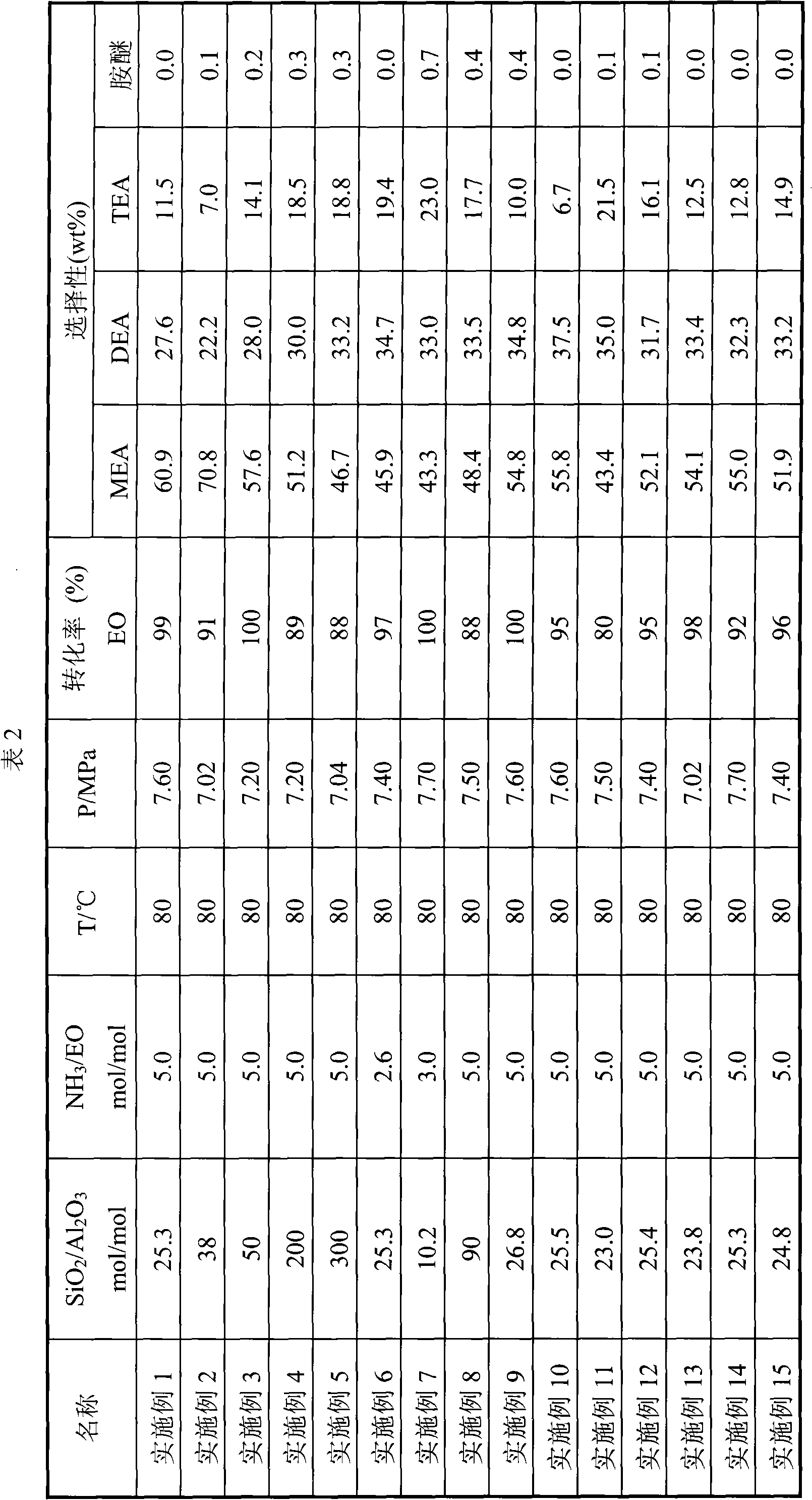

Embodiment 2~15

[0013] The preparation of the catalyst and the evaluation of the catalyst according to the various steps and conditions obtained in Example 1 are just to change the types of raw materials, crystallization conditions, calcination conditions, raw material ratios, surface treatment and catalyst molding factors and other synthesis conditions, and list the synthesis conditions In Table 1; the catalysts obtained by different synthesis methods were evaluated under the same evaluation conditions, and the evaluation results are listed in Table 2.

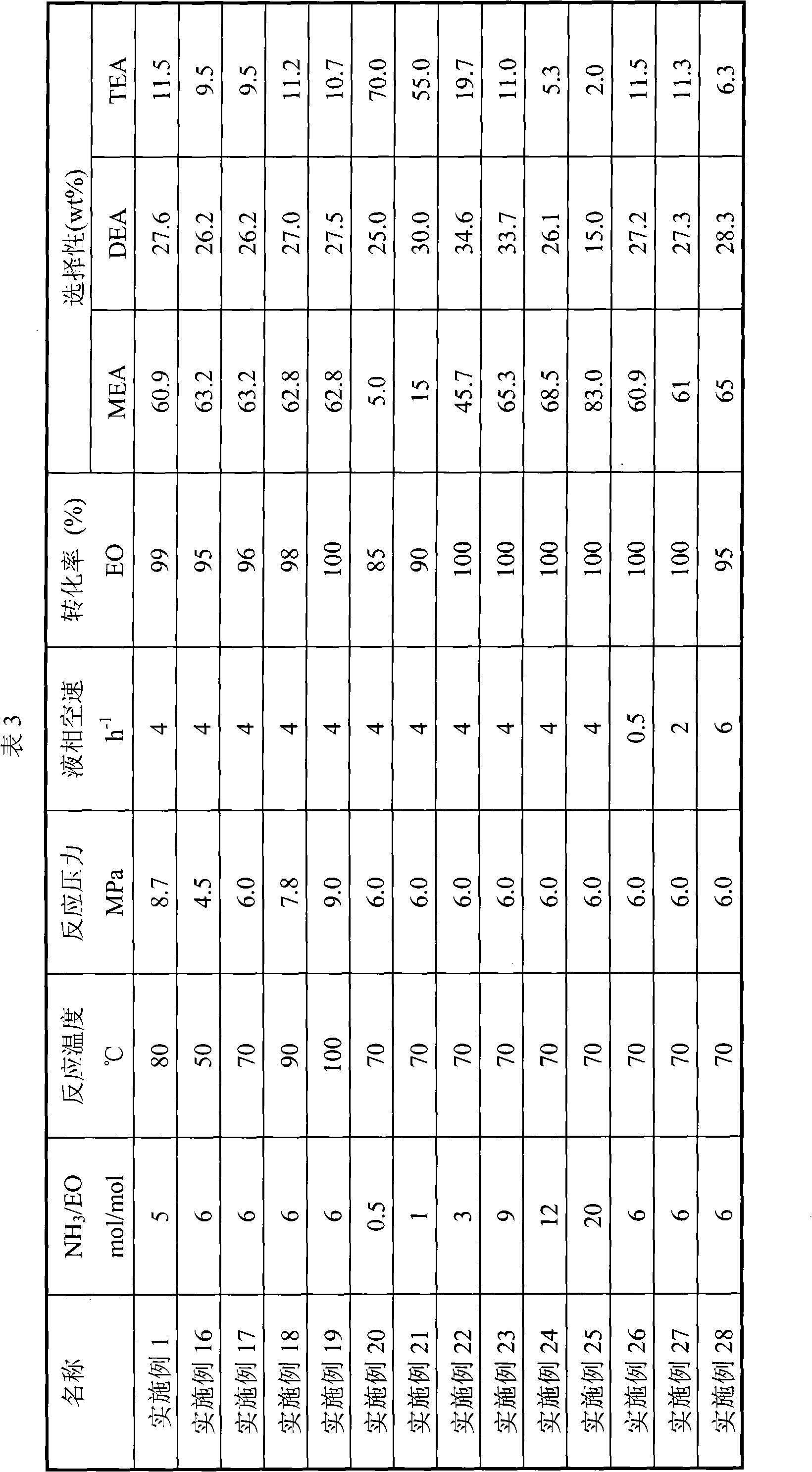

Embodiment 16~28

[0015] The catalysts were prepared and evaluated according to the steps and conditions of Example 1, except that the molar ratio of ammonia to ethylene oxide, reaction temperature, system pressure, space velocity and other process parameters were changed in the evaluation conditions, which are listed in Table 3.

[0016]

[0017]

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com