Method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide

A technology of carbon dioxide and ethylene oxide, applied in the field of carbon dioxide and ethylene oxide or propane to synthesize ethyl carbonate or propylene, can solve problems such as catalyst loss, and achieve the effects of small catalyst loss, simple reaction process and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

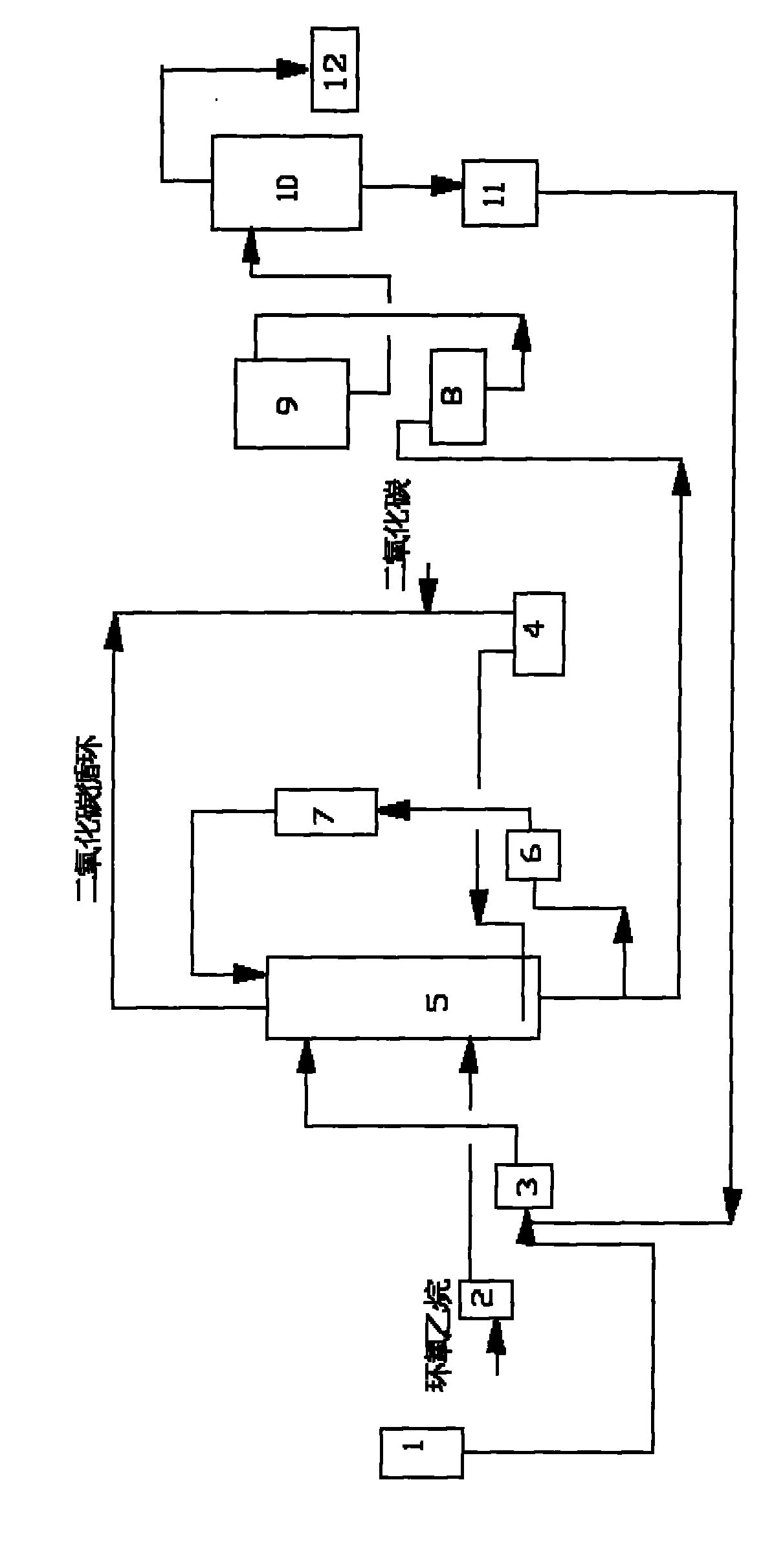

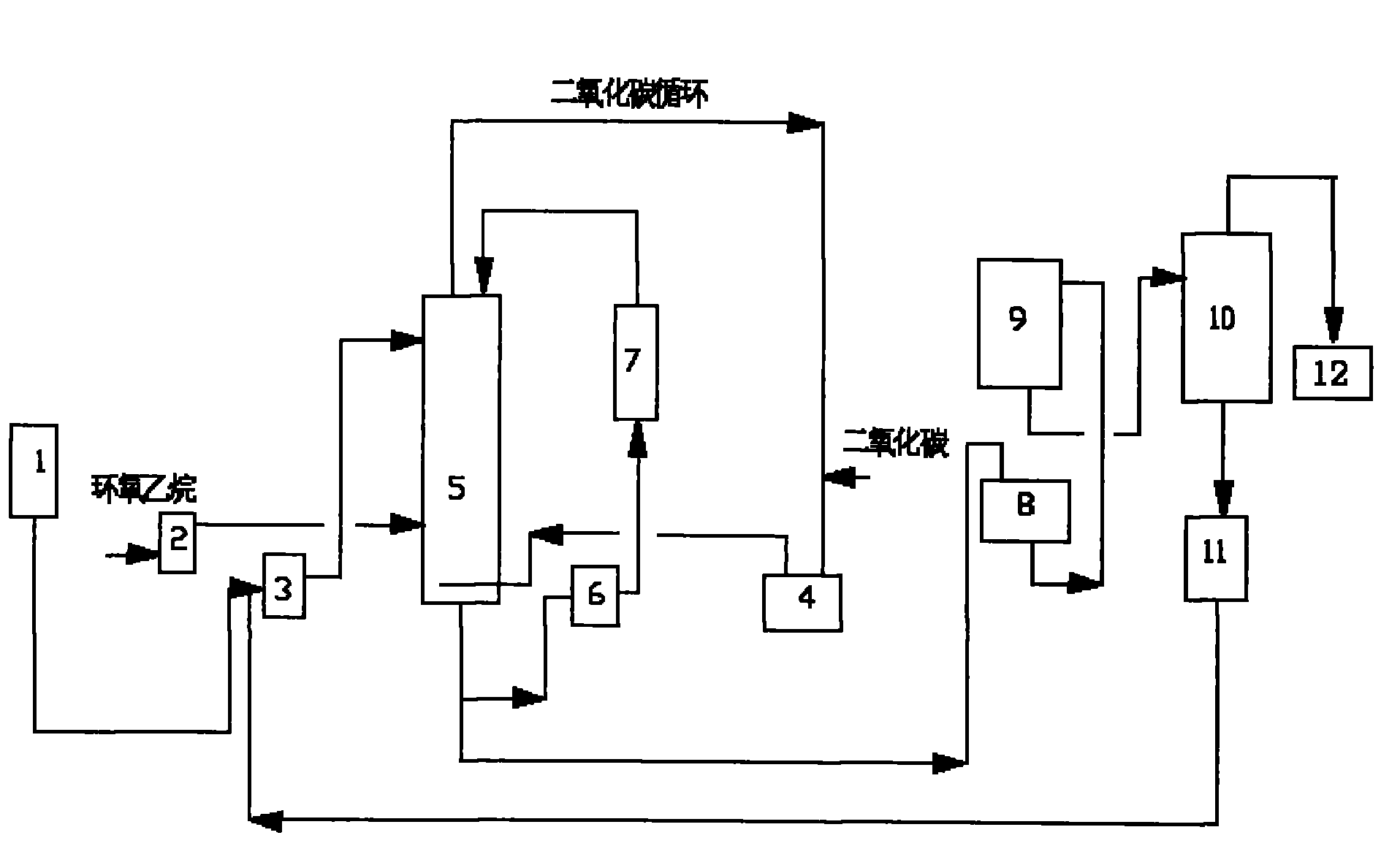

Method used

Image

Examples

Embodiment 1

[0024] The 1-methyl-3-butyl imidazolium bromide salt of 1g / h sodium carbonate and 6.5g / h joins in the tubular reactor, and the carbon dioxide of the ethylene oxide of 150g / h and 2.0MPa respectively from reactor Add at the bottom and heat to 100°C with an external heating medium to make ethylene oxide react with carbon dioxide for a residence time of 5 hours to convert to ethylene carbonate; product analysis shows that the conversion rate of ethylene oxide is 98%; the selectivity is 99%.

Embodiment 2

[0026] The 1-methyl-3-butylimidazolium tetrafluoroborate of 1g / h potassium carbonate and 6.5g / h joins in the tubular reactor, and reaction condition is identical with embodiment 1, and oxirane and carbon dioxide reaction stay Time 3 hours into ethylene carbonate; product analysis, calculated ethylene oxide conversion rate of 99%; selectivity of 99%.

Embodiment 3

[0028] Using the catalyst in Example 1, 150g / h of propylene oxide and 3.5MPa of carbon dioxide were added from the bottom of the reactor respectively, heated to 120°C with an external heating medium, and the residence time of ethylene oxide and carbon dioxide was converted for 3 hours. into propylene carbonate; product analysis, calculated conversion rate of propylene oxide was 98%; selectivity was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com