Dimethyl carbonate and ethylene glycol production process

A technology of dimethyl carbonate and ethylene glycol, which is applied in the field of new process flow for catalyzed production of dimethyl carbonate and ethylene glycol with ionic liquid composite catalyst, can solve the problem of low single-pass conversion rate of ethylene carbonate, cumbersome process flow and poor equipment Large investment and other issues, to achieve the effect of improving the conversion rate of one pass, simple process flow, and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

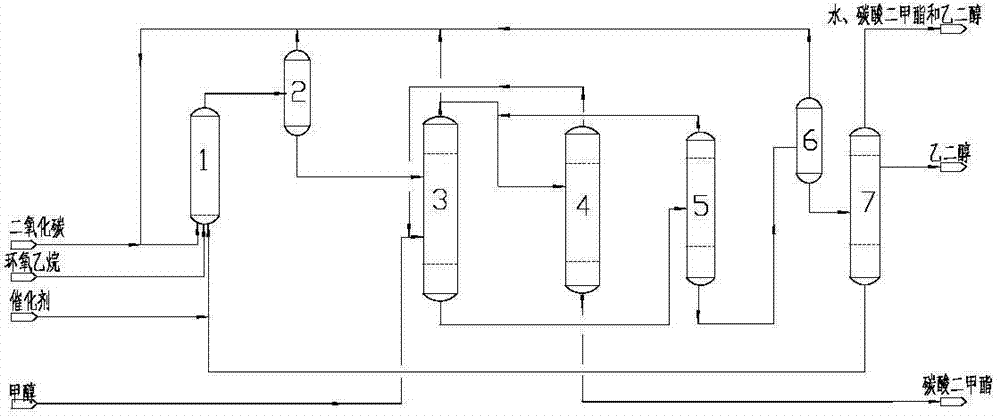

[0036] Referring to the figure, it is 0.5kg / h to produce dimethyl carbonate and ethylene glycol with the ethylene oxide feed flow as an example.

[0037] Raw material feed flow rate: ethylene oxide = 0.5 kg / h, carbon dioxide = 0.5 kg / h, methanol = 0.687 kg / h, water = 0.054 kg / h.

[0038] (1) Carbonylation step

[0039] Carbon dioxide and ethylene oxide react in the ethylene carbonate synthesis reactor 1 under the catalysis of the ionic liquid composite catalyst to generate ethylene carbonate. Theoretically, to generate 1kg of ethylene carbonate, it needs to consume 0.5kg of carbon dioxide and 0.5kg of ethylene oxide. In order to improve the conversion rate of ethylene oxide, it is necessary to increase the proportion of carbon dioxide. Excess carbon dioxide is recycled to the Ethylene carbonate synthesis reactor 1 inlet.

[0040] The operating pressure of ethylene carbonate synthesis reactor 1 is 1MPa, and the operating temperature is 190°C; the flow rates of carbon dioxide,...

Embodiment 2

[0058] Referring to the figure, the device for producing dimethyl carbonate and ethylene glycol at 0.5kg / h with ethylene oxide feed flow is an example.

[0059] Raw material feed flow rate: ethylene oxide = 0.5 kg / h, carbon dioxide = 0.5 kg / h, methanol = 0.721 kg / h, water = 0.003 kg / h.

[0060] (1) Carbonylation step

[0061] Carbon dioxide and ethylene oxide react in the ethylene carbonate synthesis reactor 1 under the catalysis of the ionic liquid composite catalyst to generate ethylene carbonate. Theoretically, 0.5 kg of carbon dioxide and 0.5 kg of ethylene oxide are required to generate 1 kg of ethylene carbonate. In order to increase the conversion rate of ethylene oxide, the proportion of carbon dioxide needs to be increased. Excess carbon dioxide is recycled to carbonic acid by flash tank and carbon dioxide compressor. Vinyl ester synthesis reactor 1 inlet.

[0062] The operating pressure of ethylene carbonate synthesis reactor 1 is 5MPa, and the operating temperatur...

Embodiment 3

[0080] Referring to the figure, the device for producing dimethyl carbonate and ethylene glycol with oxyethane feed flow as 0.5kg / h is an example.

[0081] Raw material feed flow rate: ethylene oxide = 0.5 kg / h, carbon dioxide = 0.5 kg / h, methanol = 0.714 kg / h, water = 0.018 kg / h.

[0082] (1) Carbonylation step

[0083] Carbon dioxide and ethylene oxide react in the ethylene carbonate synthesis reactor 1 under the catalysis of the ionic liquid composite catalyst to generate ethylene carbonate. Theoretically, 0.5 kg of carbon dioxide and 0.5 kg of ethylene oxide are required to generate 1 kg of ethylene carbonate. In order to increase the conversion rate of ethylene oxide, the proportion of carbon dioxide needs to be increased. Excess carbon dioxide is recycled to carbonic acid by flash tank and carbon dioxide compressor. Vinyl ester synthesis reactor 1 inlet.

[0084] Ethylene carbonate synthesis reactor 1 operating pressure is 5MPa, operating temperature is 180 ℃; Ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com