Production plant with polycrystalline silicon reduction furnaces and operation method

A production device and reduction furnace technology, applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve problems affecting reaction rate and conversion rate, uneven mixing, increasing costs, etc., to reduce tail gas treatment The effect of increasing the amount, increasing the residence time, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Taking the production process of polysilicon produced by three polysilicon reduction furnaces as an example, the main technical features of the production device and operating method that meet the technical requirements of the present invention are described as follows:

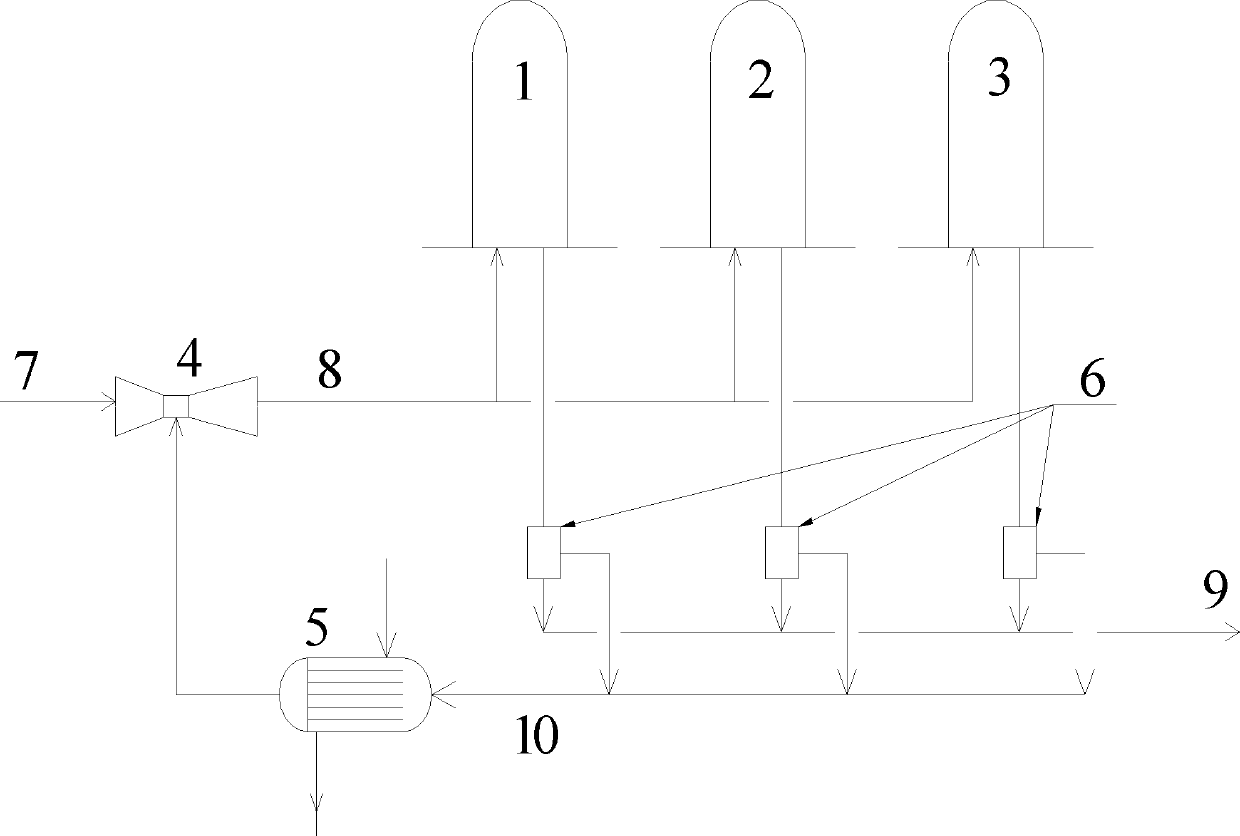

[0015] Such as figure 1 As shown, the reaction device comprises polysilicon reduction furnace I (1), polysilicon reduction furnace II (2), polysilicon reduction furnace III (3), Venturi injection device (4), cooler (5), automatic control system (6 ), fresh raw material pipeline (7), total feed pipeline (8), tail gas recovery pipeline (9), reusable material pipeline (10). The inlet pipelines of the three polysilicon reduction furnaces are all connected to the total feed pipeline (8), and the discharge pipelines of the three reduction furnaces are connected to the tail gas recovery pipeline (9) and the recyclable material pipeline (10). The furnace implements unified feeding and unified discharging. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com