Method of preparing trans-1,2-dichloroethylene from mixed chlorohydrocarbon

A technology of dichlorethylene and chlorinated hydrocarbons, which is applied in the field of comprehensive utilization of by-product mixed chlorinated hydrocarbons, can solve problems such as unsuccessful reports, achieve good social and economic benefits, be easy to operate, and solve comprehensive utilization problems problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

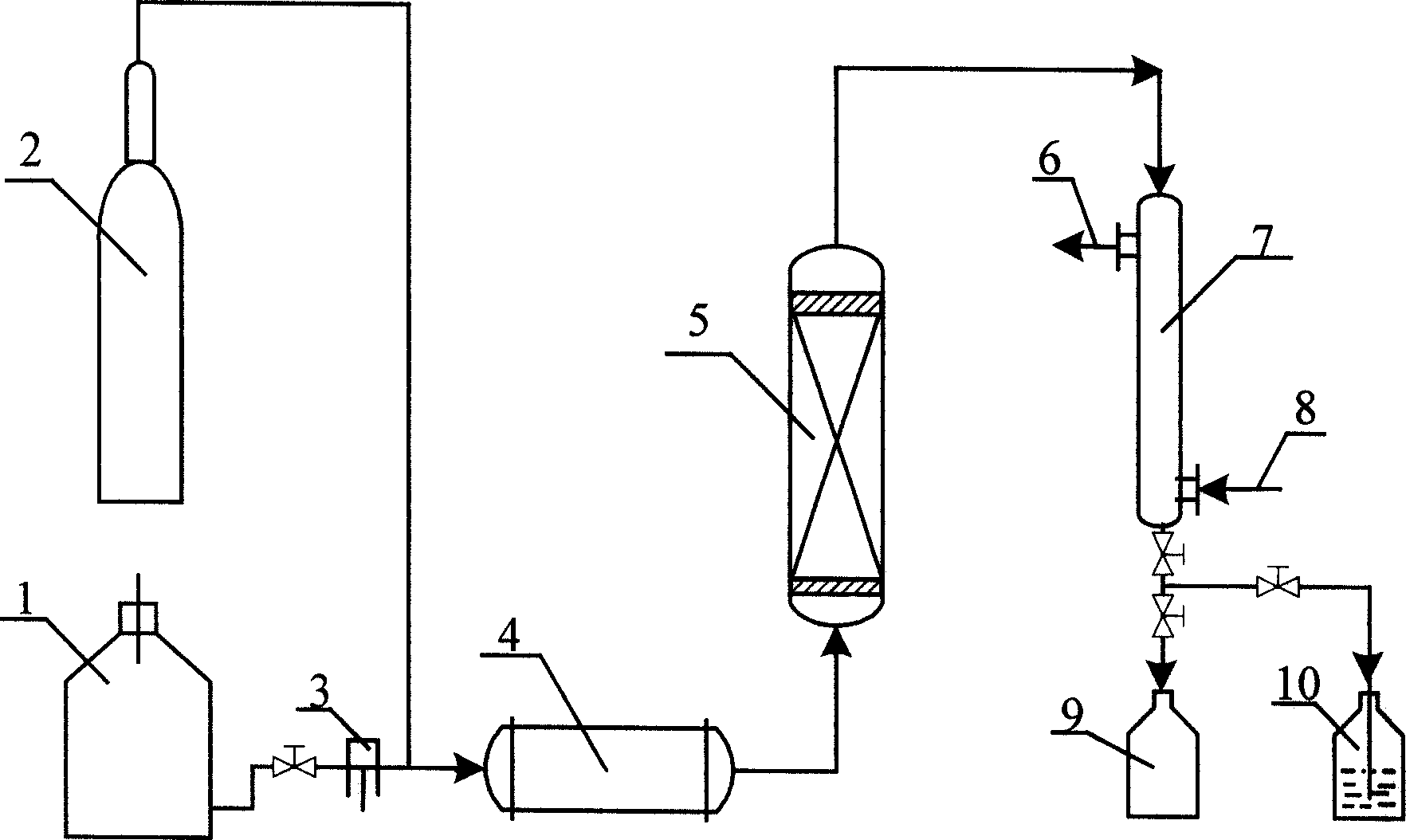

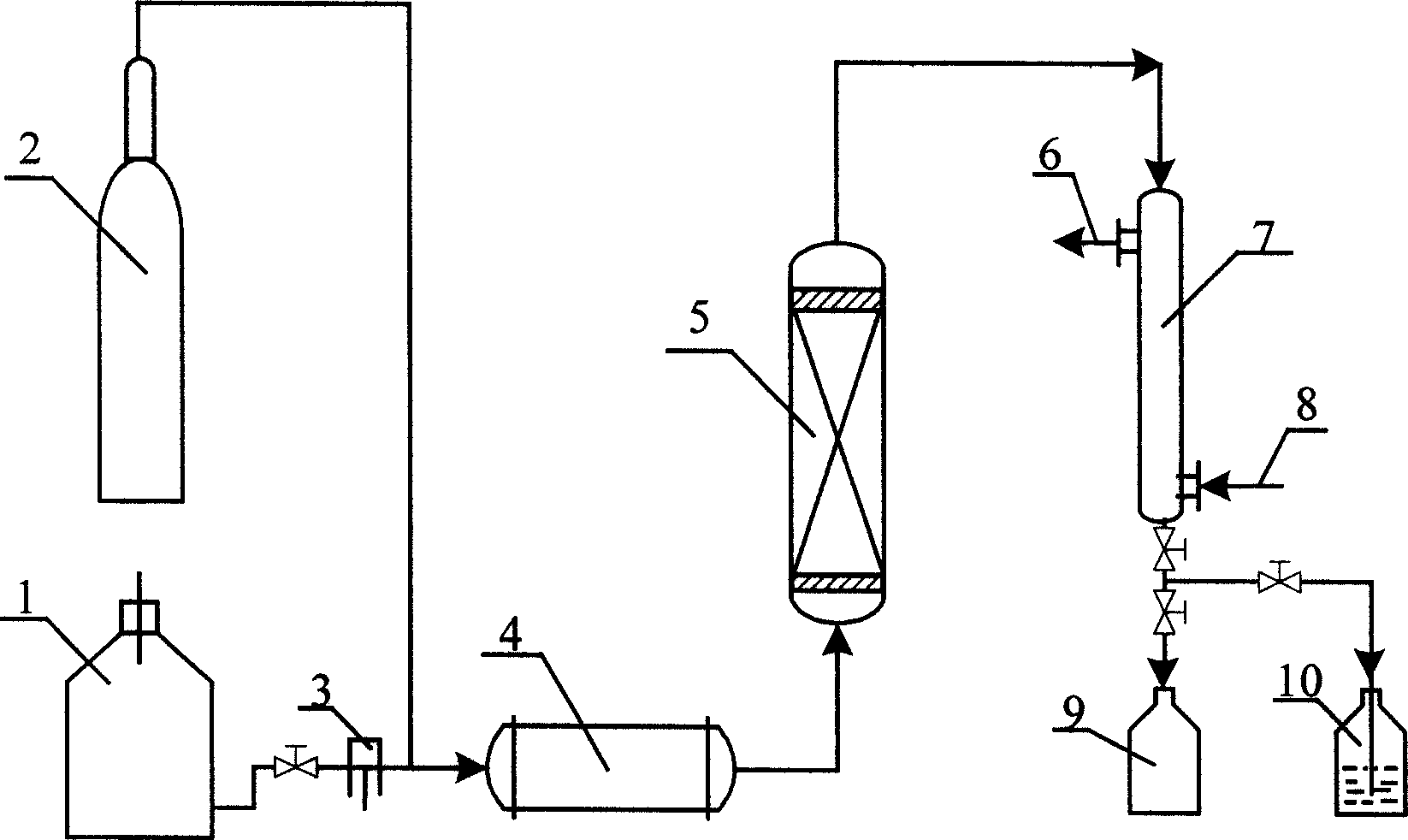

[0054] The raw material chlorinated hydrocarbon mixture is sent into the gasifier 4 by the metering pump 3, and the temperature of the gasifier 4 is maintained at 150°C. The vaporized mixed chlorinated hydrocarbon gas passes through the reactor 5 and the condenser 7 in sequence. The temperature of the reactor was 240°C. The residence time of the feed gas is 3 minutes, and the inlet temperature of the condensed water is 5°C. The product is collected by the product storage tank 9, and analyzed by gas chromatography after washing with water and alkali.

[0055] The components and weight percentages of the raw material chlorinated hydrocarbon mixture mainly include:

[0056] Vinylidene chloride 1.13% (wt)

[0057] cis-1,2-dichloroethylene 2.17% (wt)

[0058] Trans-1,2-dichloroethylene 4.21% (wt)

[0059] 1,1,2-Trichloroethylene 8.31%(wt)

[0060] 1,1,2-Trichloroethane 48.31% (wt)

[0061] 1,1,2,2-Tetrachloroethylene 15.41% (wt)

[0062] 1,1,2,2-Tetrachloroethane 19.45% (wt...

Embodiment 2

[0072] Adopt the process condition of embodiment 1, device and the composition and weight percentage of raw material chlorinated hydrocarbon mixture, wherein the residence time of raw material gas is 4min. The components and weight percentages of the chlorinated hydrocarbon mixture rich in trans-1,2-dichloroethylene after the reaction mainly include:

[0073] Vinylidene chloride 6.34% (wt)

[0074] cis-1,2-dichloroethylene 10.61% (wt)

[0075] Trans-1,2-dichloroethylene 69.76% (wt)

[0076] 1,1,2-Trichloroethylene 4.48% (wt)

[0077] 1,1,2-Trichloroethane 8.52%(wt)

[0078] 1,1,2,2-Tetrachloroethylene 0.29% (wt)

Embodiment 3

[0080] Adopt the processing condition and the device of embodiment 1. The components and weight percentages of the raw material chlorinated hydrocarbon mixture mainly include:

[0081] 1,2-Dichloroethane 5%(wt)

[0082] 1,1,2-Trichloroethane 67%(wt)

[0083] 1,1,2,2-Tetrachloroethane 21%(wt)

[0084] Pentachloroethane 5% (wt)

[0085] Other polychlorinated hydrocarbons 1.94% (wt)

[0086] The components and weight percentages of the chlorinated hydrocarbon mixture rich in trans-1,2-dichloroethylene after the reaction mainly include:

[0087] Vinylidene chloride 5.16% (wt)

[0088] cis-1,2-dichloroethylene 11.25% (wt)

[0089] Trans-1,2-dichloroethylene 66.99% (wt)

[0090] 1,2-dichloroethane 2.32% (wt)

[0091] 1,1,2-Trichloroethylene 7.73% (wt)

[0092] 1,1,2-Trichloroethane 5.82%(wt)

[0093] 1,1,2,2-Tetrachloroethylene 0.73% (wt)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com