Reaction system for producing polycrystalline silicon by using multiple polycrystalline silicon reduction furnaces and operating method of reaction system

A technology of a reaction system and an operation method, which is applied to the field of reaction systems for producing polysilicon in multiple polysilicon reduction furnaces, can solve the problems of heat waste, weak turbulence of reactants, and increased costs, and achieves reduction in energy input, increase in feed flow, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

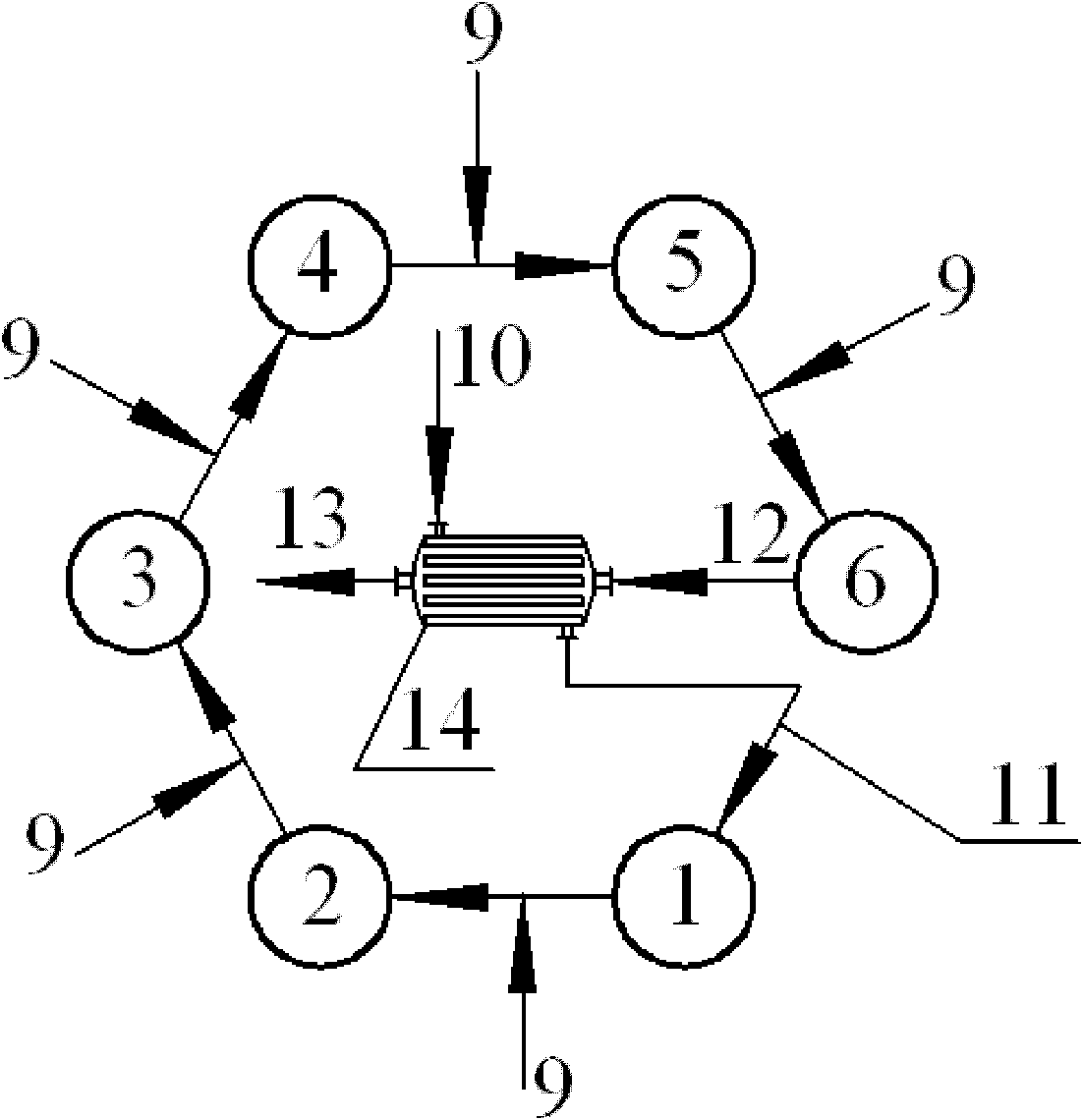

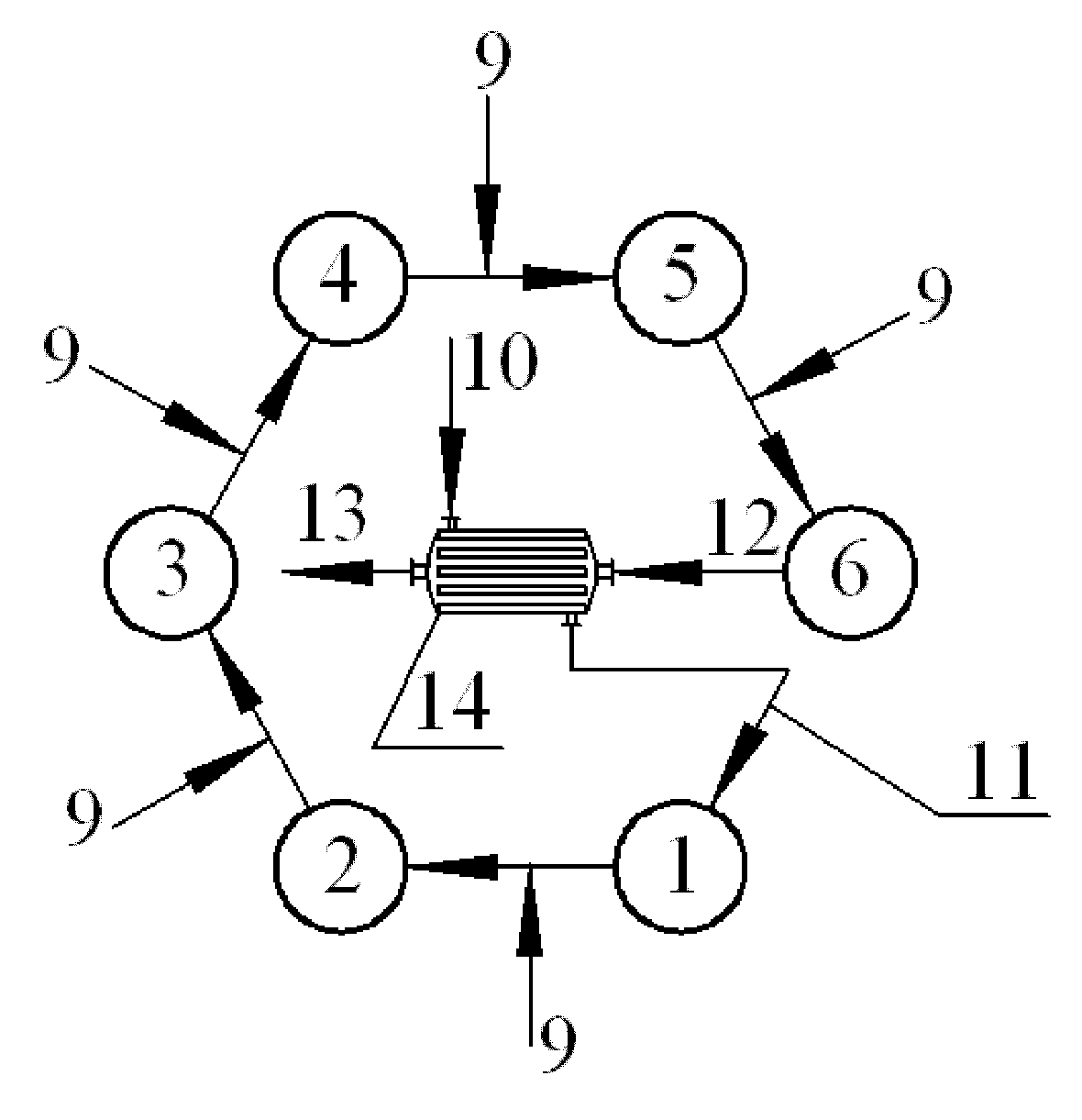

[0018] Taking the production process of six polysilicon reduction furnaces in parallel to produce polysilicon as an example, the main technical features of the reaction system and process flow that meet the technical requirements of the present invention are described as follows:

[0019] Such as figure 2 As shown, six polysilicon reduction furnaces are connected in series in sequence, except for the No. The discharge port of a reduction furnace is connected, for example, the feed port of No. 3 reduction furnace 3 is connected with the discharge port of No. 2 reduction furnace; in addition, there is a pipeline supply Fresh hydrogen 9. The two inlets of the heat exchanger 14 in the system are respectively connected to the feed 10 and the outlet tail gas 12 of the No. 6 reduction furnace 6, and the two outlets are respectively connected to the feed 11 of the No. 1 reduction furnace 1 and the final tail gas discharge port 13.

[0020] The embodiment corresponding to the techno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com