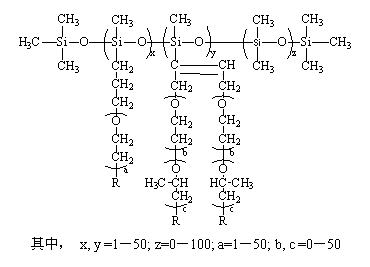

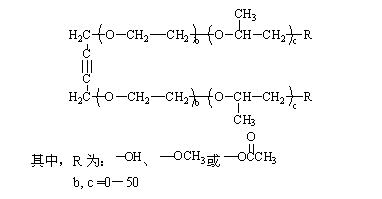

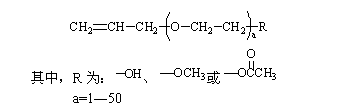

Alkynyl diol ethyl oxide polyether or alkynyl diol propyl oxide polyether co-modified polysiloxane and preparation method thereof

A technology of acetylene glycol propoxide and ethoxide, which is applied in the field of acetylene glycol ethoxide polyether or acetylene glycol propoxide polyether co-modified polysiloxane, can solve the problem of high equilibrium surface tension, high Low surface tension, more foam, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, add 16.58Kg allyl polyether (APEO-7), 1.87Kg butynediol monoethoxy ether and 32.05Kg hydrogen-containing silicone oil (the mass fraction of active hydrogen is 0.52%) into the reaction kettle, and then add Chloroplatinic acid and ruthenium chloride (based on the ratio of the mass of Pt and Ru contained in the catalyst to the total mass of the three raw materials are respectively 50mg / kg and 50mg / kg), using isopropanol as solvent, at a temperature of 130°C condition, N 2 React under protection for 7 hours. The solvent isopropanol and low boiling point components were distilled off to finally obtain an amber transparent viscous liquid product which was butynediol monoethoxy ether polyether co-modified polysiloxane with a viscosity of 566 mPa·s. The surface tension of its aqueous solution was measured with a K-12 surface tensiometer to be 22mN / m. The critical micelle concentration of the aqueous solution is 387mg / L. At the same time, the minimum contact angle of i...

Embodiment 2

[0036] First, add 24.83Kg of methyl-terminated allyl polyether, 7.61Kg of butynediol diethoxy ether and 16.76Kg of hydrogen-containing silicone oil (the mass fraction of active hydrogen is 1.32%) into the reaction kettle, and then add card Karstedt platinum catalyst (20 mg / kg based on the ratio of the mass of Pt contained in the catalyst to the total mass of the three raw materials), using methanol as a solvent, at a temperature of 240 ° C, N 2 Reaction under protection for 16 hours. The solvent methanol and low boiling point components were distilled off to obtain a yellowish brown clear viscous liquid product which was butynediol diethoxy ether polyether co-modified polysiloxane with a viscosity of 279 mPa·s. The surface tension of its aqueous solution was measured with a K-12 surface tensiometer to be 20mN / m. The critical micelle concentration is 203mg / L. At the same time, the minimum contact angle of its aqueous solution on the surface of polytetrafluoroethylene is 20°, ...

Embodiment 3

[0038] First, add 6.47Kg of methyl-terminated allyl polyether, 14.98Kg of butynediol monopropoxy ether and 19.43Kg of hydrogen-containing silicone oil (the mass fraction of active hydrogen is 0.51%) into the reaction kettle, and then add chlorine Platinic acid and ruthenium chloride solution (respectively 80mg / Kg and 80mg / Kg based on the ratio of the Pt and Ru mass contained in the catalyst to the total mass of the three raw materials) were used as catalysts, and isopropanol was used as a solvent at a temperature of At 170°C, N 2 Reaction under protection for 13 hours. The solvent isopropanol and low boiling point components were distilled off to finally obtain an orange-yellow clear viscous liquid product which was butynediol monopropoxy ether polyether co-modified polysiloxane with a viscosity of 367 mPa·s. Structural characterization of the product was carried out by proton nuclear magnetic resonance spectrometer and infrared spectrometer (see attached figure 1 ,2), by an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com