Crude oil desalting composition and method of use thereof

A composition and desalination technology, which is applied in the fields of hydrocarbon oil dehydration/demulsification, petroleum industry, refined hydrocarbon oil, etc., can solve the problems affecting the normal operation of the electric desalination process, the inability to effectively separate oil and water, and the current increase of the electric desalination process , to achieve significant demulsification and desalination effects, strengthen the effect of electric field, and destroy the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

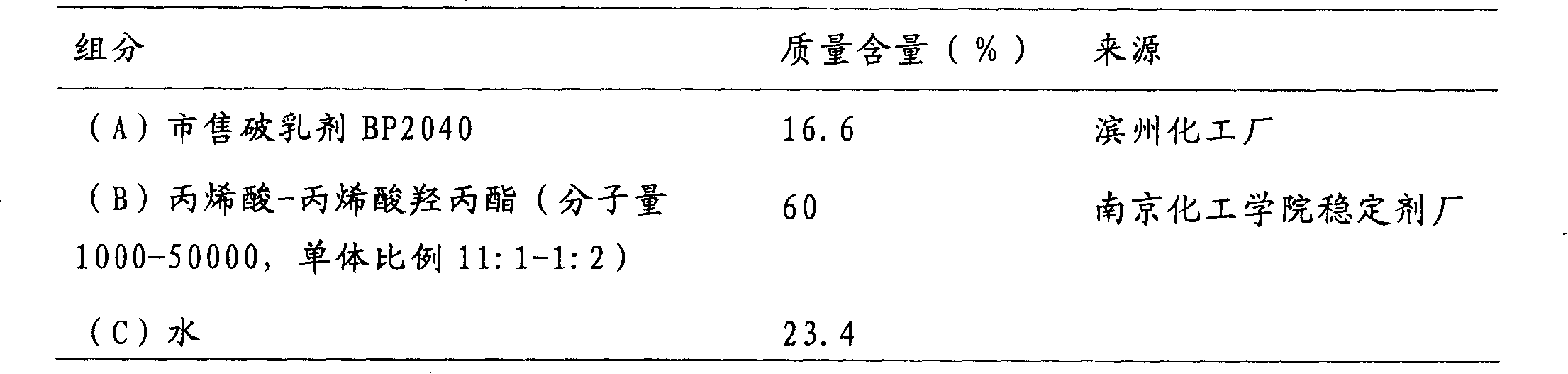

[0036] Preparation of desalination composition 1

[0037] Desalination Composition 1 was prepared by mixing the following components (A), (B) and (C) in the ratio given below.

[0038]

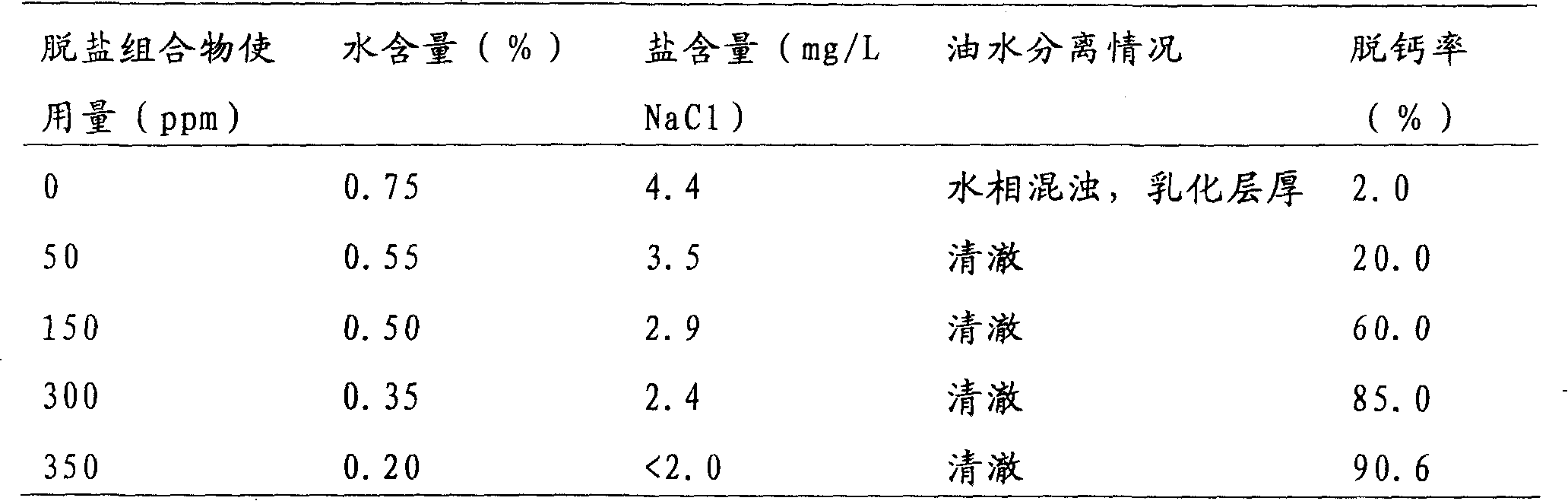

[0039] Sour crude oil desalting using desalting composition 1

[0040] The acid-containing heavy oil and kerosene in the ninth district of Karamay were prepared according to the volume ratio of 7:3 to prepare the experimental oil (salt content 4.4mg / L NaCl, calcium content 154ppm). Based on the quality of the oil used in the experiment, 10% water injection and the desalination composition used in the amount shown in Table 1 below were formulated into an aqueous solution. The prepared aqueous solution and the raw material oil preheated to 90-100°C were thoroughly mixed for 20 seconds on a commercially available fruit juice blender, and then poured into a conical glass desalination tank. The DP-II electric desalination demulsifier is used for oil-water separation, the electric field gradien...

Embodiment 2

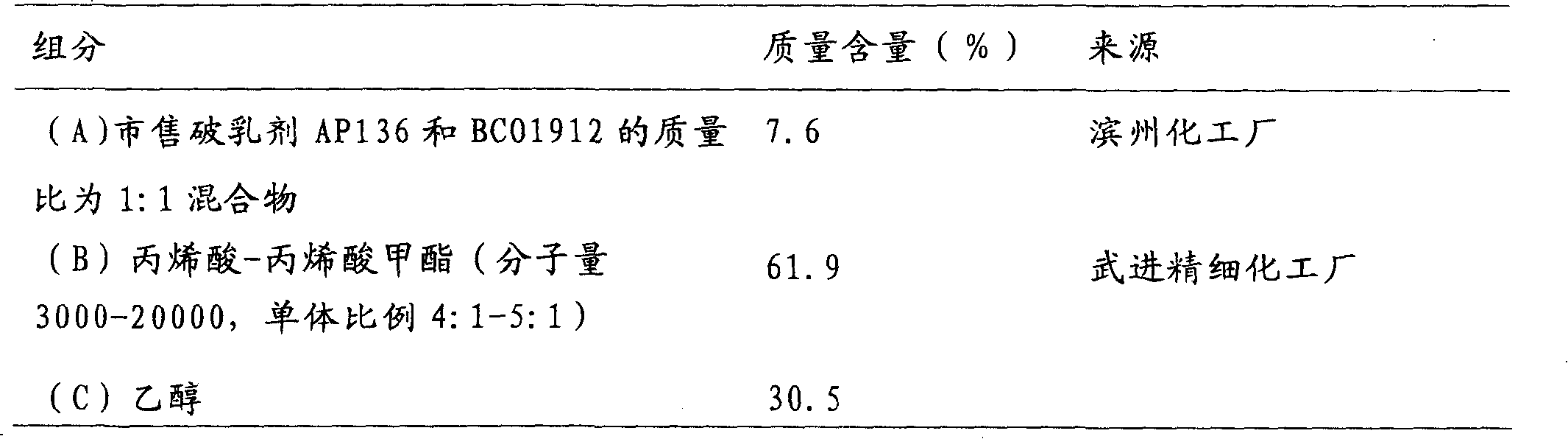

[0045] Preparation of desalination composition 2

[0046] The desalting composition 2 was prepared by mixing the following components (A), (B) and (C) in the ratio given below.

[0047]

[0048] Sour crude oil desalting using desalting composition 2

[0049] Liaohe heavy oil and kerosene were prepared in a volume ratio of 8:2 to prepare experimental oil (salt content 29mg / LNaCl, calcium content 360ppm). Desalting was performed according to the method of Example 1 using desalting composition 2. The measurement results are shown in Table 2.

[0050] Table 2 Desalting treatment results of Liaohe heavy oil / kerosene mixed oil by desalting composition 2

[0051]

[0052] Note: The qualified standards for water content and salt content in crude oil are water content ≤ 0.2%, salt content ≤ 3mg / L NaCl.

Embodiment 3

[0054] Preparation of desalination composition 3

[0055] The desalination composition 3 was prepared by mixing the following components (A), (B) and (C) in the ratio given below.

[0056]

[0057] Sour crude oil desalting using desalting composition 3

[0058] The oil used in the experiment was Dagang oil (salt content 23.1mg / L NaCl, calcium content 15ppm). Desalting was performed according to the method of Example 1 using desalting composition 3. The measurement results are shown in Table 3.

[0059] Table 3 desalination composition 3 to the desalination treatment result of Dagang Oil

[0060]

[0061] Note: The qualified standards for water content and salt content in crude oil are water content ≤ 0.2%, salt content ≤ 3mg / L NaCl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com