Crude de-emulsifier and its preparing process

A crude oil demulsifier and demulsifier technology, applied in the direction of hydrocarbon oil dehydration/demulsification, petroleum industry, etc., can solve the problem of neglecting new demulsifiers, and achieve good demulsification performance, large molecular weight, and the effect of promoting oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

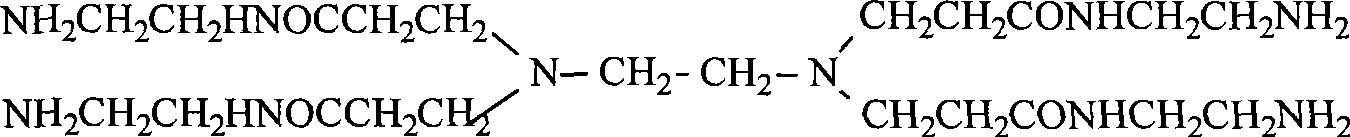

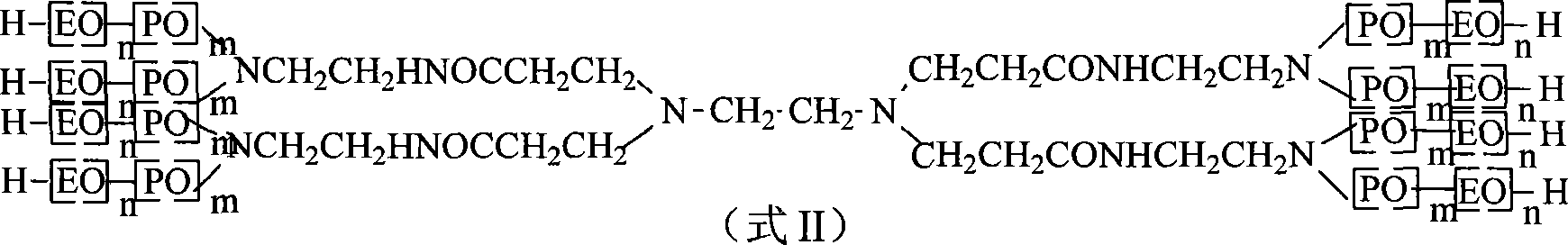

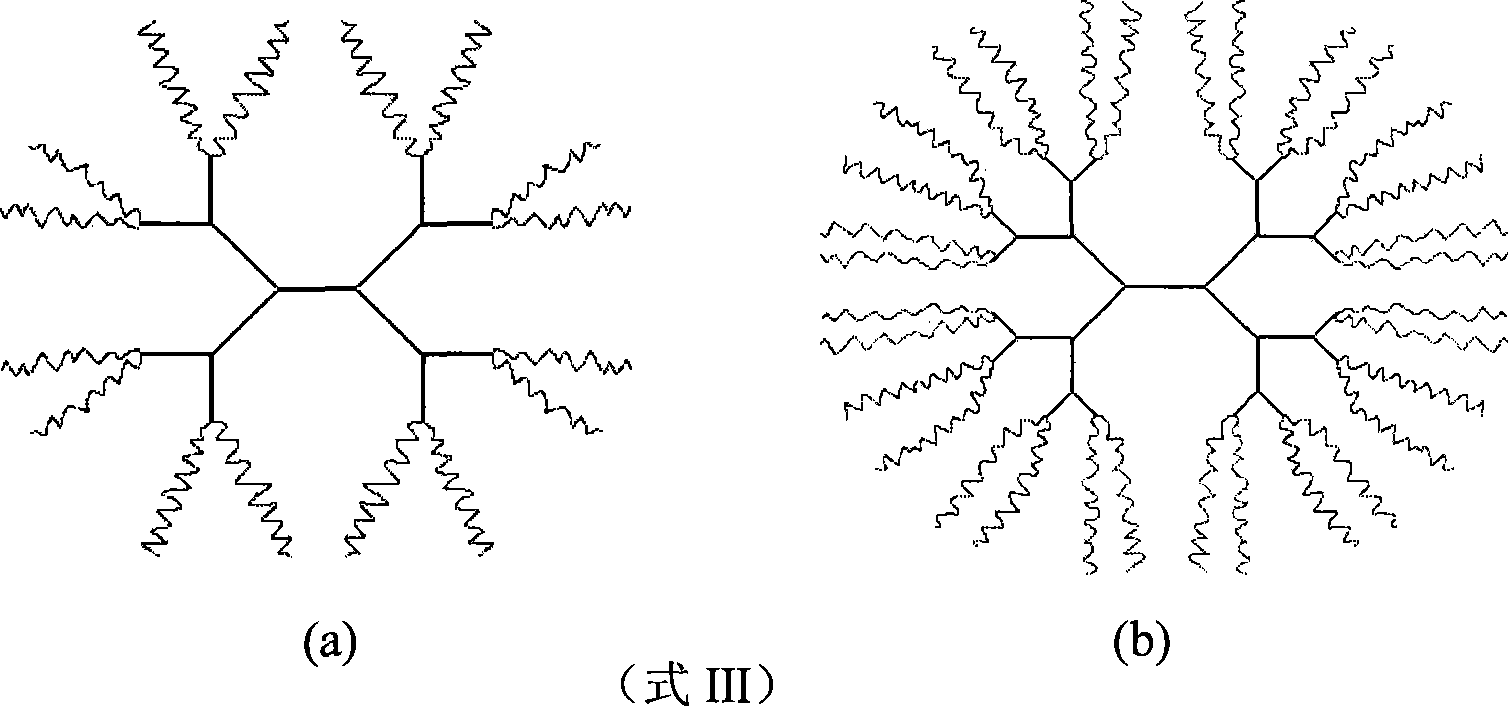

[0021] Embodiment 1: the synthesis of demulsifier A

[0022] (1) Add 1g of 1.0 generation polyamidoamine and 1g of KOH into the autoclave;

[0023] (2) Seal the reaction kettle system, and replace the air in the autoclave, feeding kettle and feeding pipe with nitrogen.

[0024] (3) Stir and heat up, when the temperature rises to 100°C, slowly add 100g of propylene oxide, control the reaction temperature at 120-140°C, and the pressure at 0.2-0.4Mpa.

[0025] (4) After the reaction is completed, age for 1 hour and cool down to 100°C.

[0026] (5) 100g ethylene oxide is added to the feed tank, and reacted under the same conditions as (3). The reaction product is neutralized to neutral with phosphoric acid to obtain demulsifier A.

Embodiment 2

[0027] Embodiment 2: the synthesis of demulsifier B

[0028] (1) Add 1g of 2.0 generation polyamidoamine and 1g of KOH into the autoclave;

[0029] (2) Seal the reaction kettle system, and replace the air in the autoclave, feeding kettle and feeding pipe with nitrogen.

[0030] (3) Stir and heat up, when the temperature rises to 100°C, slowly add 100g of propylene oxide, control the reaction temperature at 120-140°C, and the pressure at 0.2-0.4Mpa.

[0031] (4) After the reaction is completed, age for 1 hour and cool down to 100°C.

[0032] (5) 100g ethylene oxide is added to the feed tank, and reacted under the same conditions as (3). The reaction product is neutralized to neutral with phosphoric acid to obtain demulsifier B.

Embodiment 3

[0033] Embodiment 3: the synthesis of demulsifier C

[0034] (1) Add 1g of 3.0 generation polyamidoamine and 1g of KOH into the autoclave;

[0035] (2) Seal the reaction kettle system, and replace the air in the autoclave, feeding kettle and feeding pipe with nitrogen.

[0036] (3) Stir and heat up, when the temperature rises to 100°C, slowly add 100g of propylene oxide, control the reaction temperature at 120-140°C, and the pressure at 0.2-0.4Mpa.

[0037] (4) After the reaction is completed, age for 1 hour and cool down to 100°C.

[0038] (5) 100g ethylene oxide is added to the feed tank, and reacted under the same conditions as (3). The reaction product is neutralized to neutral with phosphoric acid to obtain demulsifier C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com