Plywood aldehyde-free soybean protein glue and preparation method thereof

A technology for soybean protein glue and plywood, which is used in the preparation of animal glue or gelatin, protein adhesives, adhesives, etc. Moderate, excellent water and corrosion resistance, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

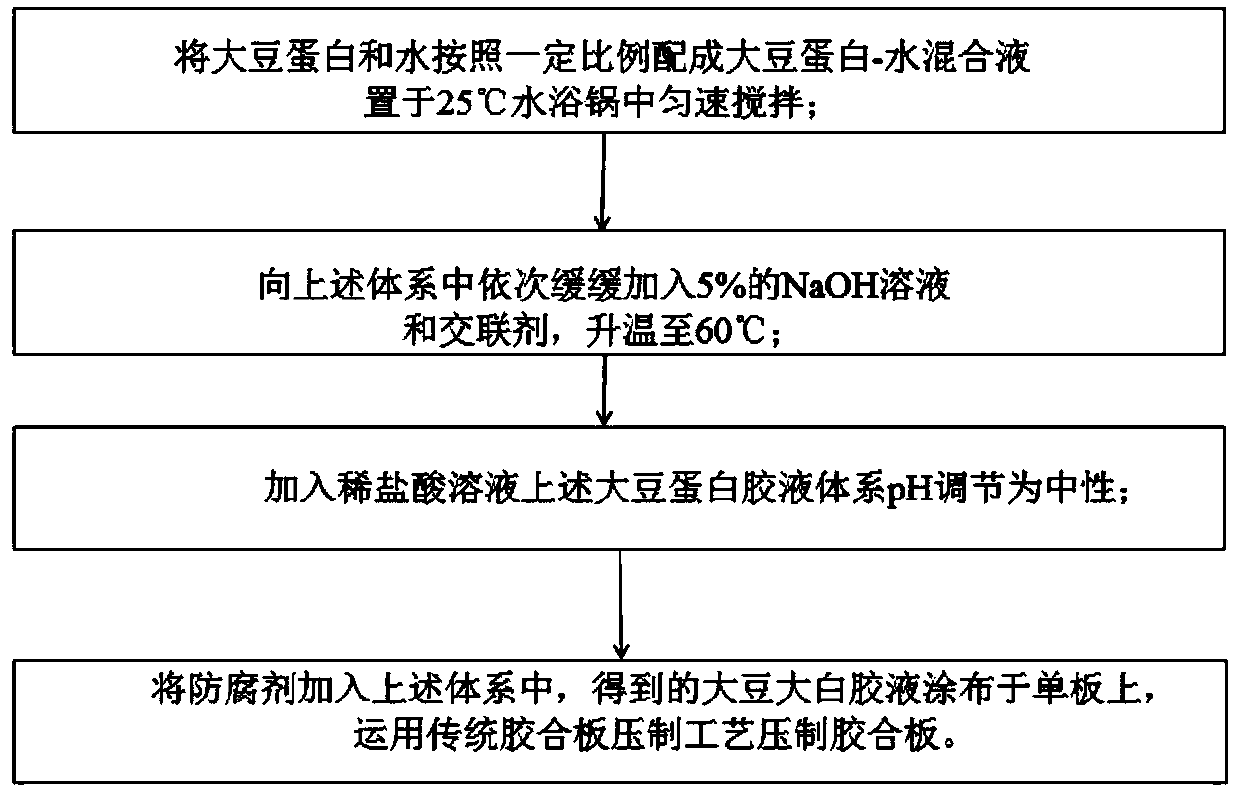

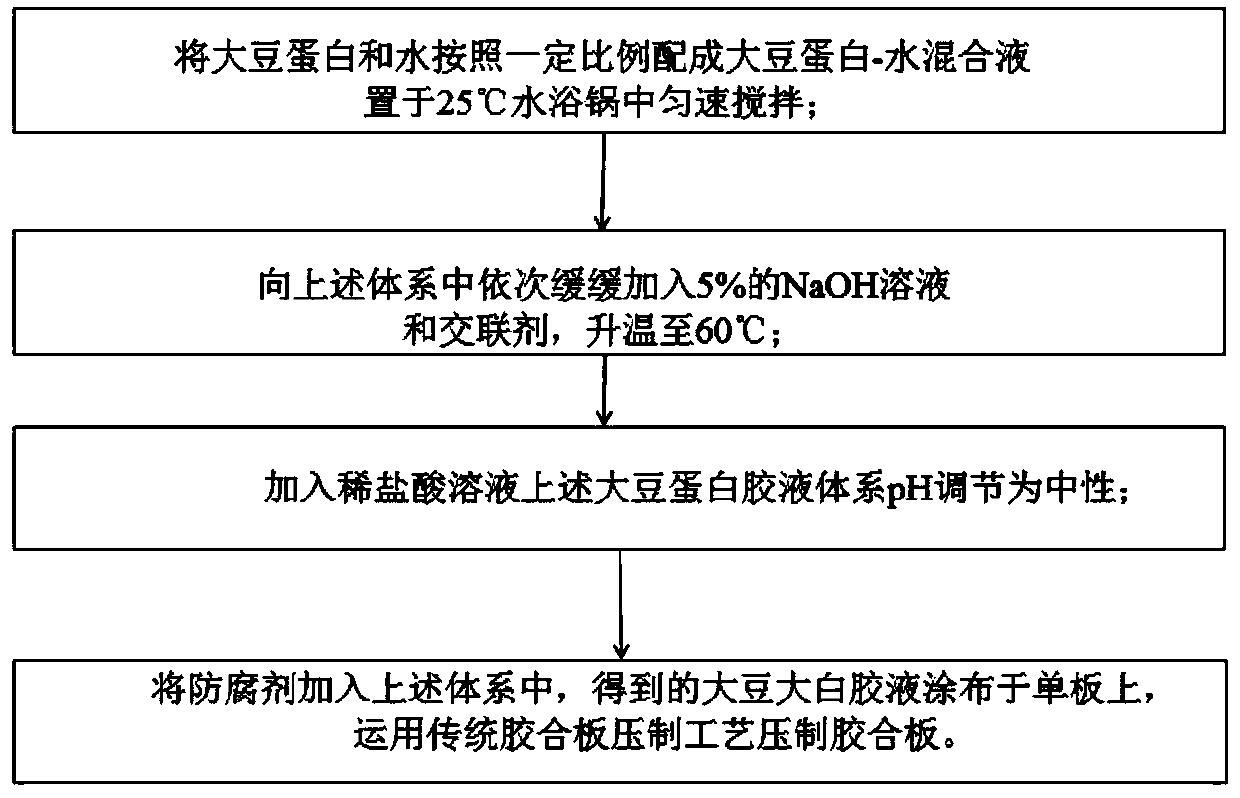

Image

Examples

Embodiment 1

[0021] The formula of formaldehyde-free soybean protein glue for plywood: 25 parts of soybean protein powder with particle size of 80 mesh, 200 parts of deionized water, 25 parts of sodium hydroxide solution with a mass concentration of 5%, 20 parts of polyamide polyamine epichlorohydrin resin PAE Crosslinker, 5 parts copper sulfate, pH 7.0.

[0022] The preparation method of plywood formaldehyde-free soybean protein glue, concrete steps are as follows:

[0023] (1) In a 500mL beaker, sequentially add 25 parts of soybean protein isolate powder with a particle size of 80 mesh, mix with 200 parts of deionized water, place in a water bath at 25°C, and stir at a constant speed of 1000r / min;

[0024] (2) Measure 25 parts of sodium hydroxide solution with a mass concentration of 5% and place it in the mixed solution obtained in step (1), and slowly heat up to 60° C. at a heating rate of 1° C. / min;

[0025] (3) Measure 20 parts of polyamide polyamine epichlorohydrin resin PAE crossl...

Embodiment 2

[0029] The formula of formaldehyde-free soybean protein glue for plywood: 25 parts of soybean protein powder with particle size of 80 mesh, 250 parts of deionized water, 35 parts of sodium hydroxide solution with a mass concentration of 5%, 25 parts of polyamide polyamine epichlorohydrin resin PAE Crosslinker, 10 parts copper sulfate, pH 7.0.

[0030] The preparation steps are the same as in Example 1.

[0031] Under this formula, the viscosity of soybean protein glue is 54s, the water absorption rate is 100%, and the storage period is 25 days; the dry bonding strength of birch plywood obtained by pressing soybean protein glue is 1.7 MPa, and the wet bonding strength is 0.98 MPa.

Embodiment 3

[0033] The formula of formaldehyde-free soybean protein glue for plywood: 25 parts of soybean protein powder with particle size of 80 mesh, 300 parts of deionized water, 30 parts of sodium hydroxide solution with a mass concentration of 5%, 20 parts of polyamide polyamine epichlorohydrin resin PAE Crosslinker, 5 parts sodium tetraborate, pH 7.0.

[0034] The preparation steps are the same as in Example 1.

[0035] Under this formula, the viscosity of soybean protein glue is 50s, the water absorption rate is 110%, and the storage period is 28 days; the dry state bonding strength of birch plywood obtained by pressing soybean protein glue is 1.6 MPa, and the wet state bonding strength is 0.82 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com