Solar cell welding and pressing device

A technology for solar cells and pressing components, applied in welding equipment, non-electric welding equipment, metal processing, etc., can solve problems such as insecure product quality, high production costs, and cumbersome procedures, and achieve excellent and stable quality, convenient maintenance, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

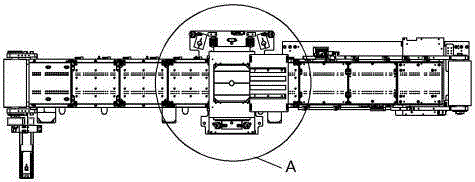

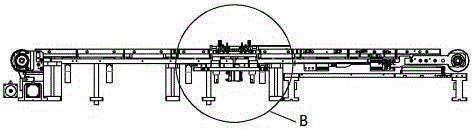

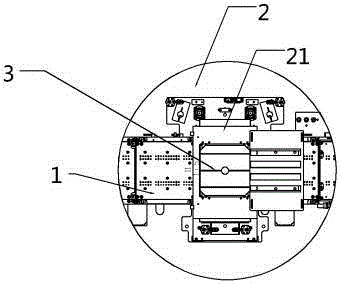

[0017] Such as Figure 1-Figure 4 As shown, the present invention provides a preferred welding and holding device for solar cells, the high-temperature conveying line 1 passes through the pressing assembly 2, and the pressing assembly 2 includes pressing pins 21, guide plates 22, pull Spring 23, bearing seat 24, guide shaft 25, fixed plate 26, upper and lower cylinders 27 of the pressing pin, the described pressing assembly 2 is installed on the high temperature conveying line 1 through the fixed plate 26, and the two sides of the fixed plate 26 pass through The bearing seat 24 is fixed with a guide shaft 25 , the top of the guide shaft 25 is connected with the guide plate 22 through the tension spring 23 , and the guide plate 22 is connected with the pressing pin 21 .

[0018] Preferably, the indenter 21 includes an indenter beam 211, an indenter mounting plate 212, a steel wire installation plate 213, and a steel wire 214, the indenter beam 211 is connected to the guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com