Patents

Literature

145results about How to "Excellent and stable quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-line quality evaluation and real-time intelligent control method for tobacco process parameter

InactiveCN101488024ACorrected intelligent dynamic controlImprove matchTotal factory controlProgramme total factory controlData managementQuality assessment

The invention discloses a method for online quality evaluation and real-time intelligent control of a parameter during a process for processing tobacco. The method comprises the following steps: a parameter value between an operating parameter of raw material processing equipment and inner quality of a processed product is preset through a data management system; online acquisition is carried out in real time through a data management acquisition system; a parameter acquired by real-time online acquisition is compared with the preset parameter value through an intelligent control system of a data management layer; a valve, a draught fan and an air door power element on the equipment and parameter regulation of tobacco strip remoistening and rotating speed of a conditioning cylinder can be controlled through regulating the operating parameter of the PLC control system and a setting value of a PID open-close loop automation control parameter, thereby realizing accurate and dynamic control of raw material quality variation tendency during a tobacco online processing process and ensuring that the inner quality of the product can be controlled in an excellent and stable range in real time. The method is applicable to control of inner index in a tobacco primary processing line, a tobacco beating and redrying line, a CO2 swelling tobacco line and a rolling, connecting and packaging processing process.

Owner:QINHUANGDAO TOBACCO MACHINERY

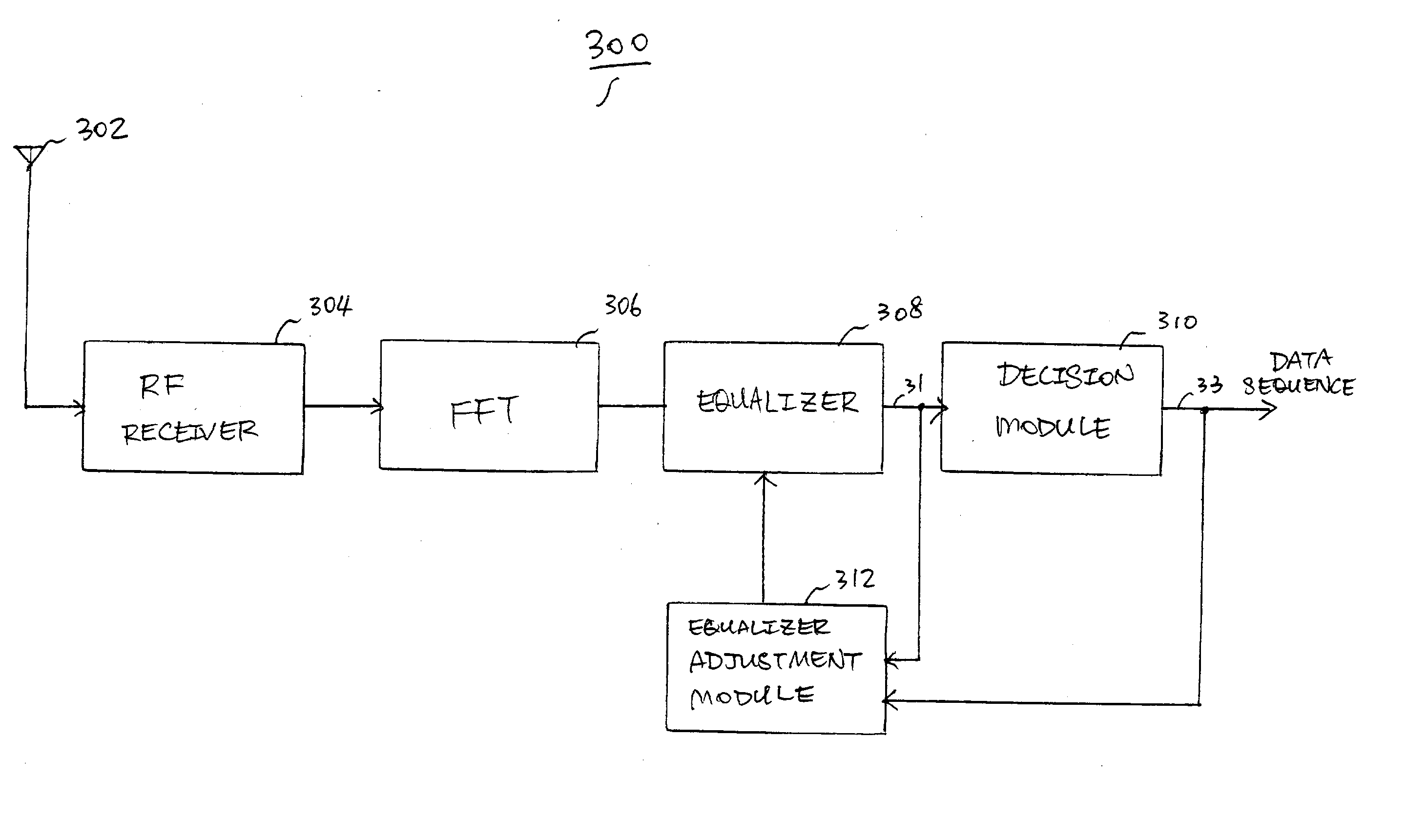

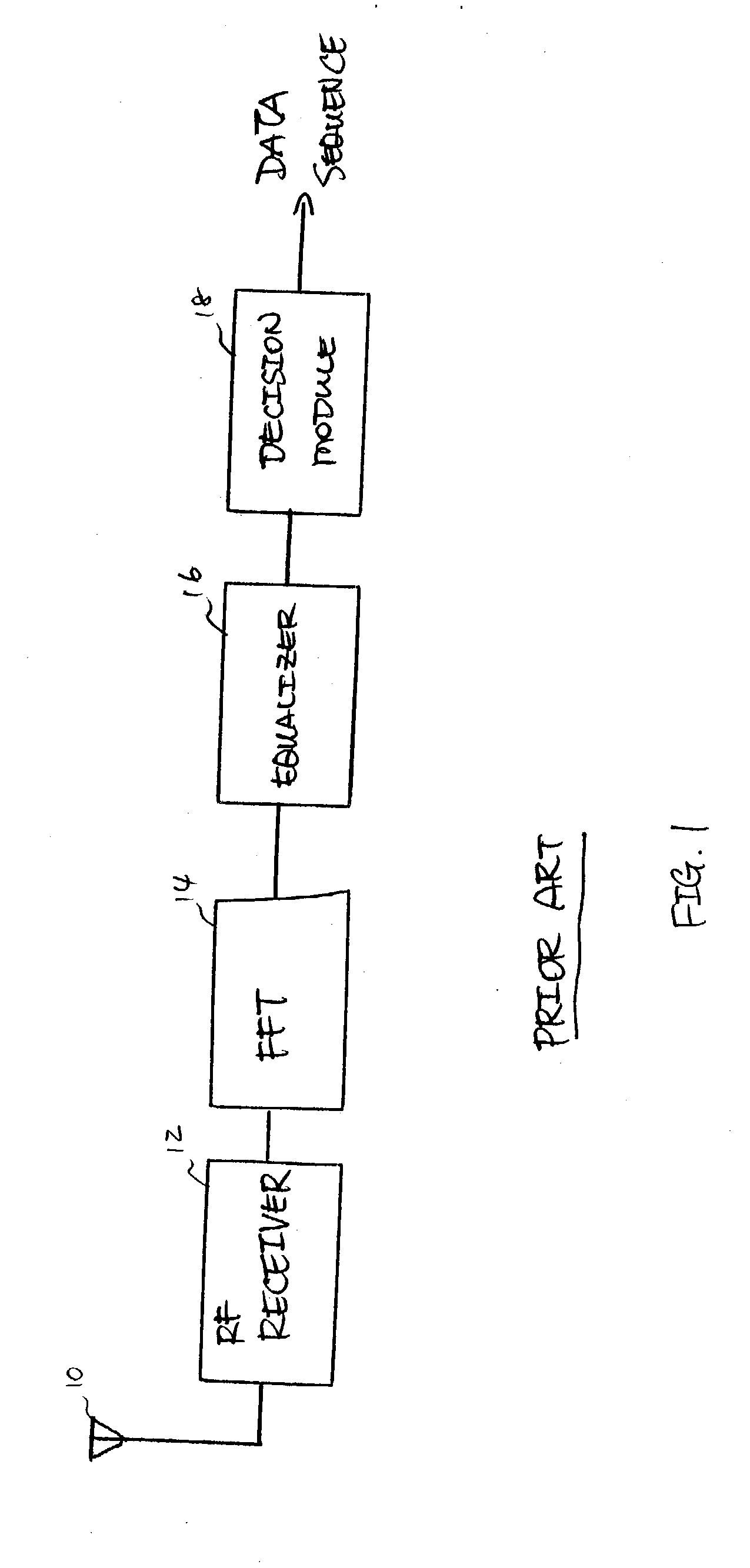

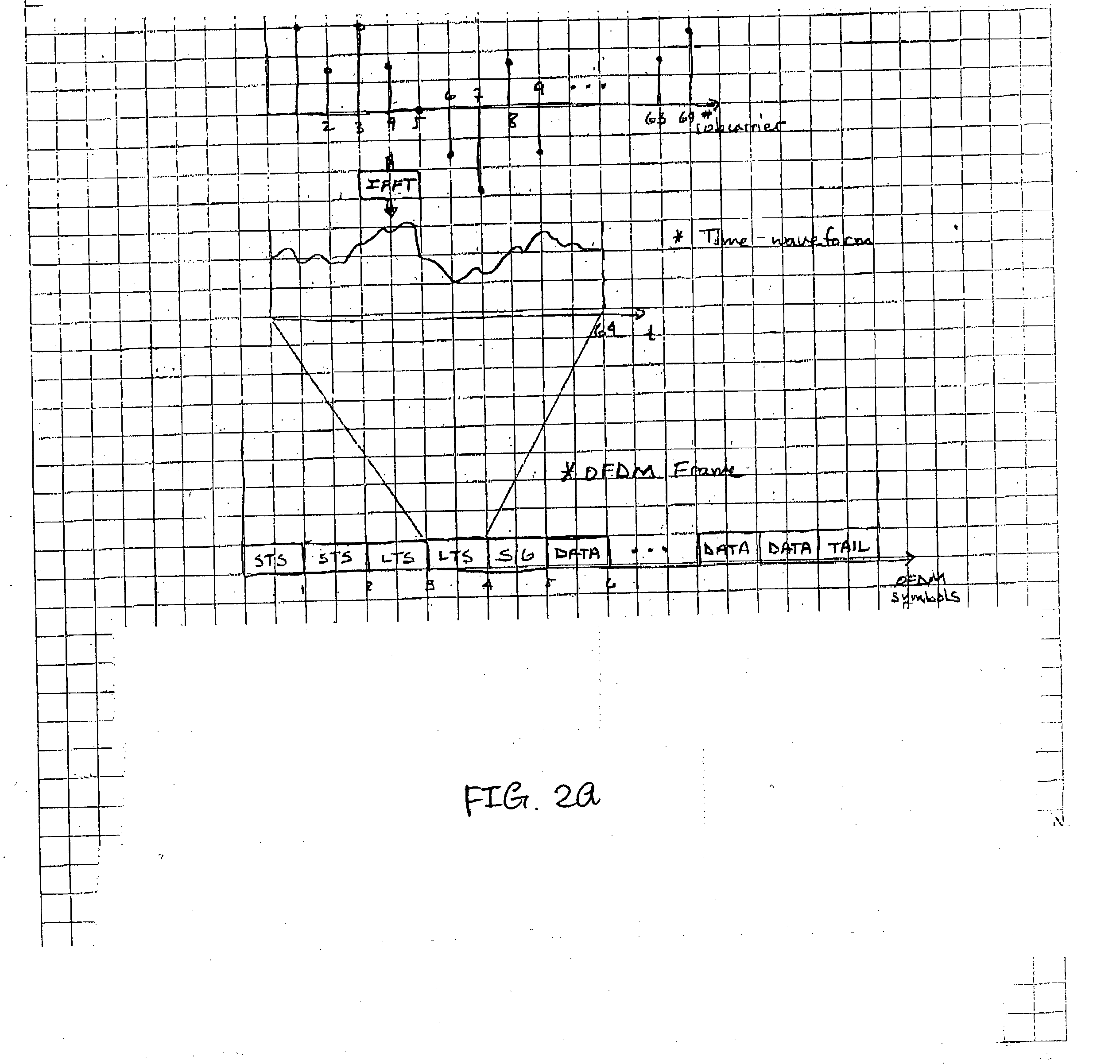

Communication system with adaptive channel correction

InactiveUS20040228417A1Excellent and stable qualitySecret communicationChannel estimationFactor baseCommunications system

Adaptive methods and systems for applying a channel correction factor to received signals to correct errors caused by channel distortion. The channel correction factor is dynamically calculated and updated based on the received signal or signals. A receiver continuously calculates an error factor representing a deviation of the received signal from the signal being transmitted, and generates the channel correction factor based on the error factor. Since the error factor includes information related to channel distortions, the channel correction factor so calculated adapts to the change of channel characteristics. If preferred, an advanced algorithm can be used to predict the channel response for the next incoming signal such that the receiver can correct channel errors on a substantially real-time basis.

Owner:RES TRIANGLE INST

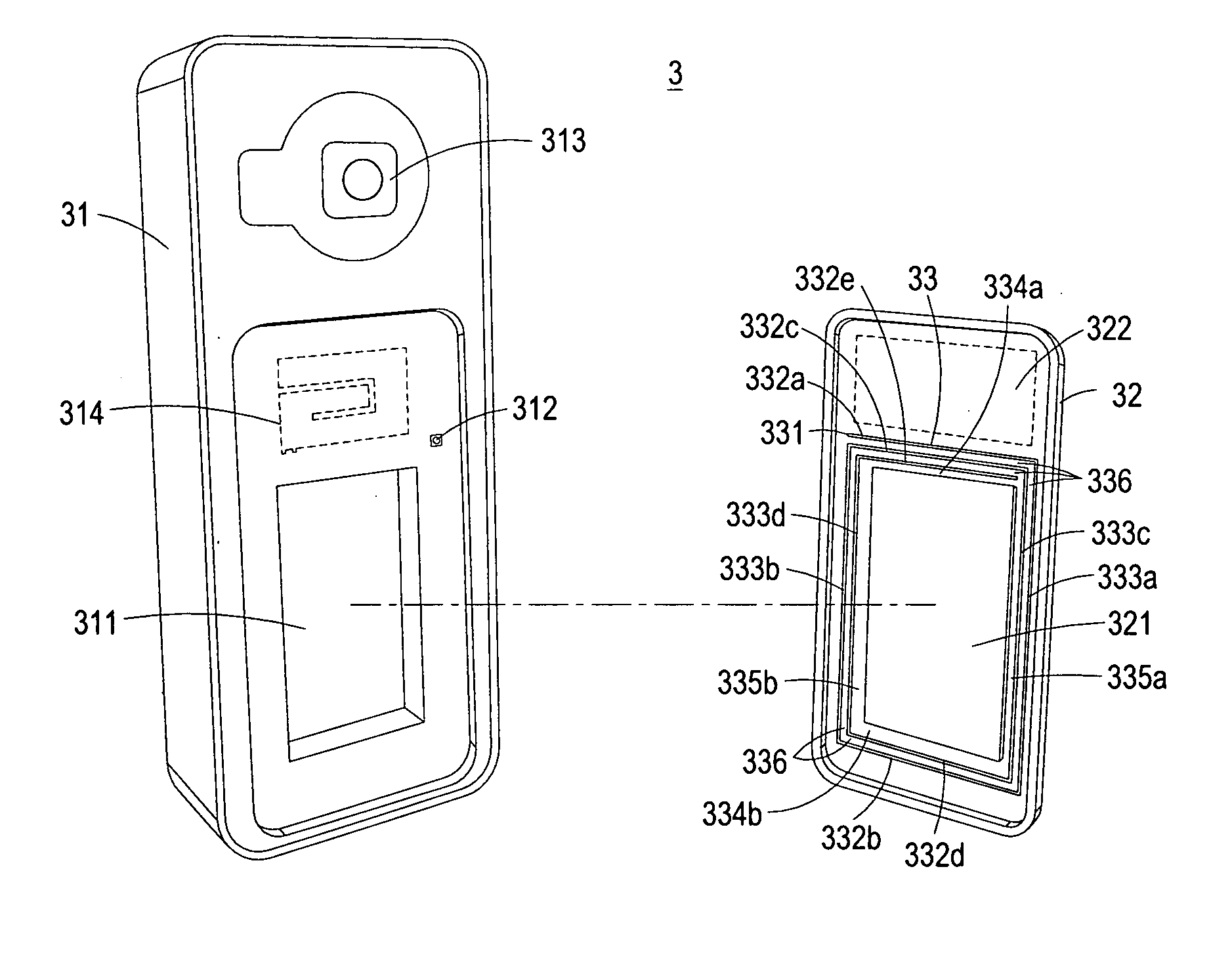

Portable electronic device with broadcast antenna

InactiveUS20090312069A1Longer path lengthExcellent and stable qualitySubstation equipmentLoop antennasEngineeringBroadcasting

The present invention is related to a portable electronic device with broadcast antenna at least including a main body having a battery accommodating space; a cover having a battery area corresponding to the battery accommodating space of the main body, wherein the shape and size of the cover are adapted to cover the battery accommodating space and the cover is separablely assembled with the corresponding outer edge of the battery accommodating space of the main body; and a broadcast antenna, disposed on the inner surface of the cover other than the battery area for unidirectionally receiving broadcasting signals in a first frequency band.

Owner:ARIMA COMM CORP LTD

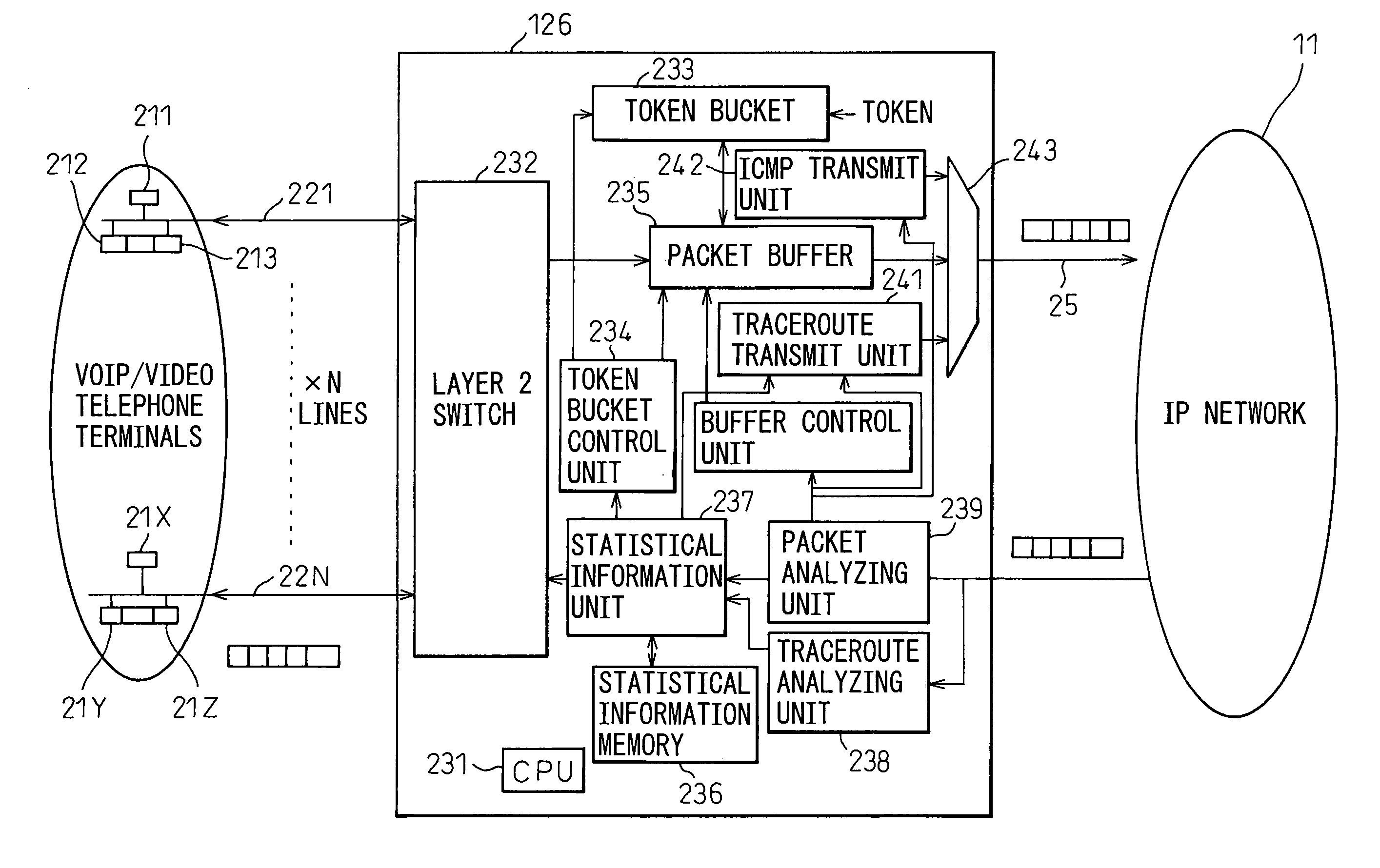

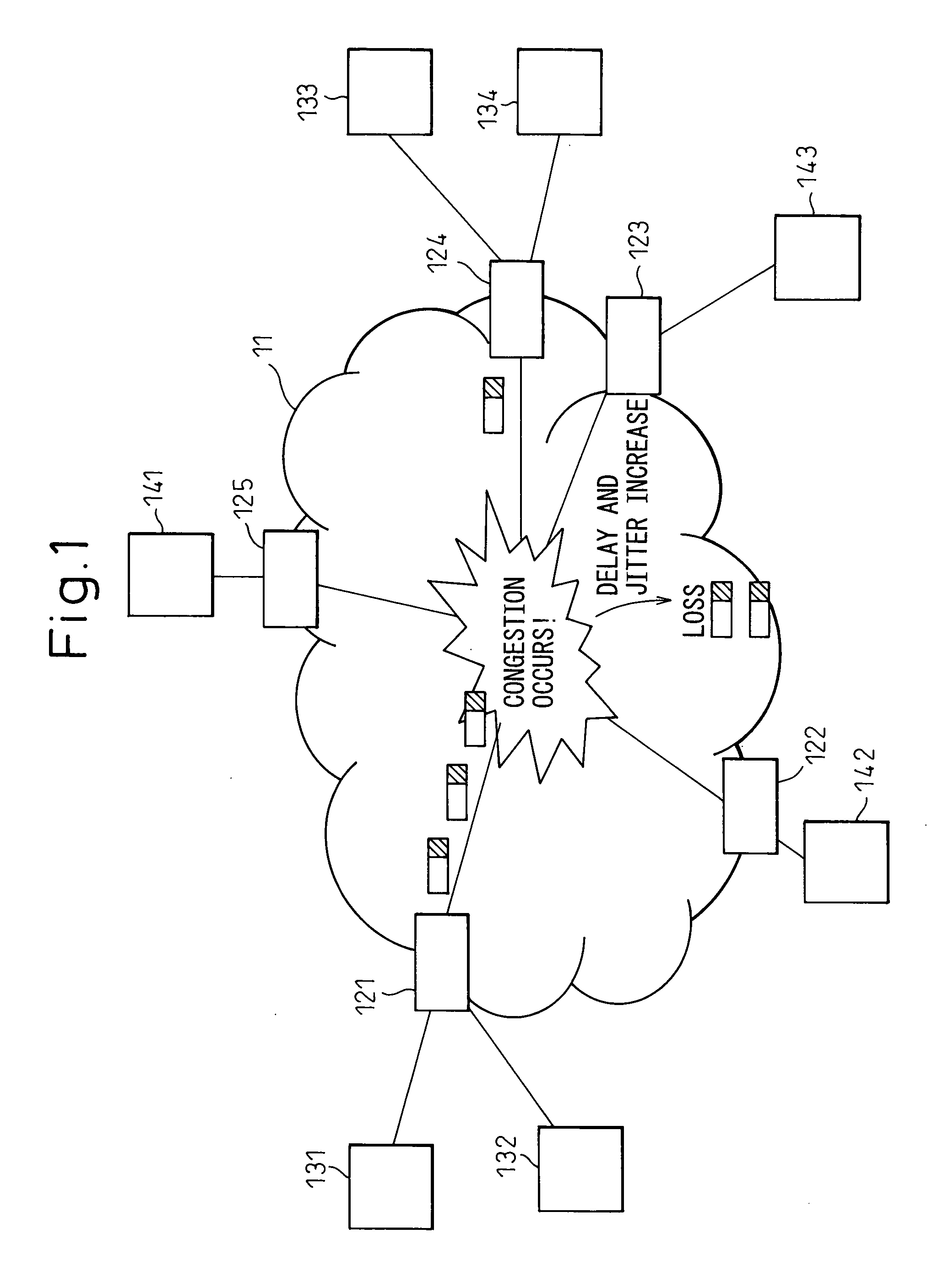

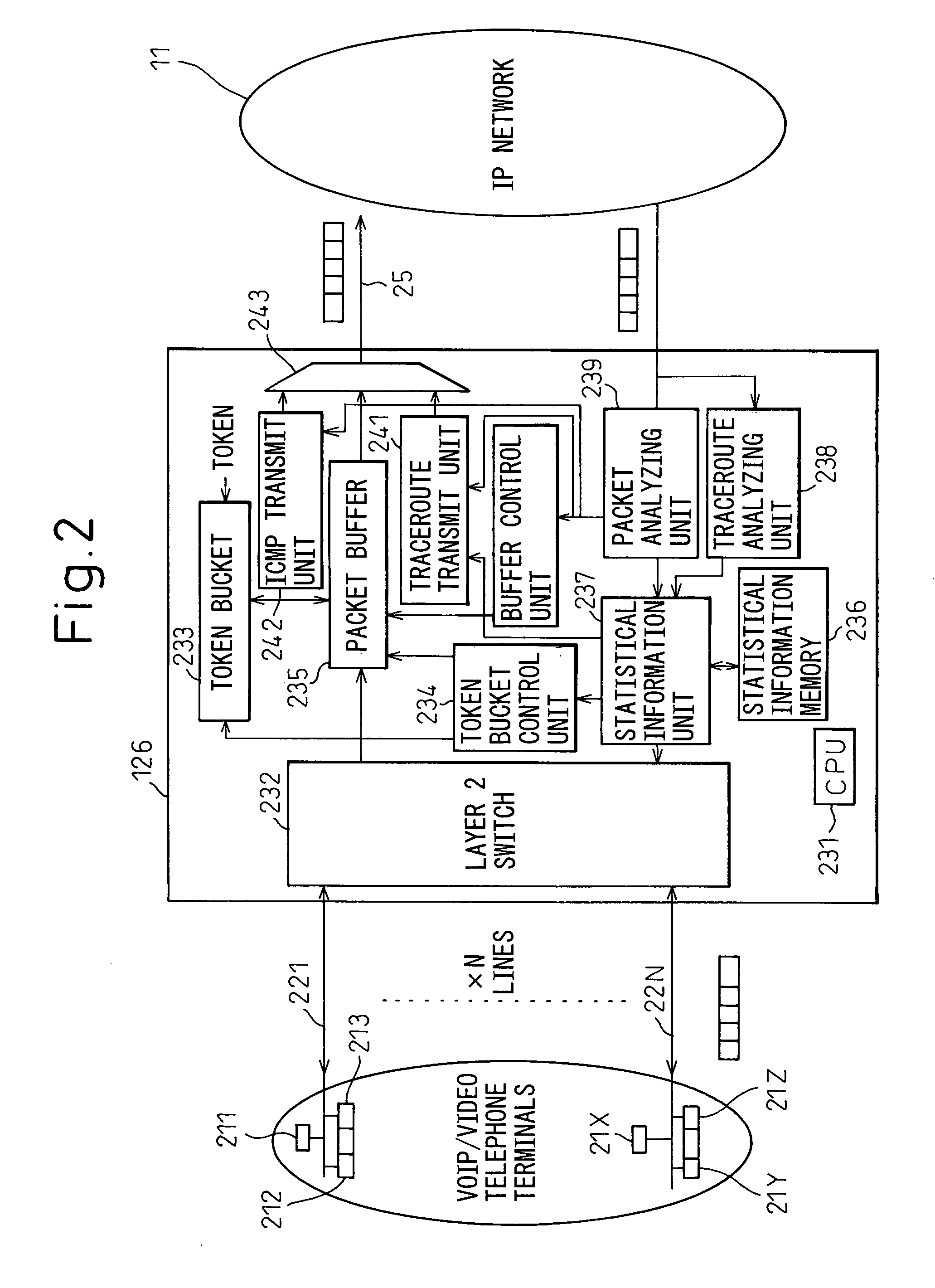

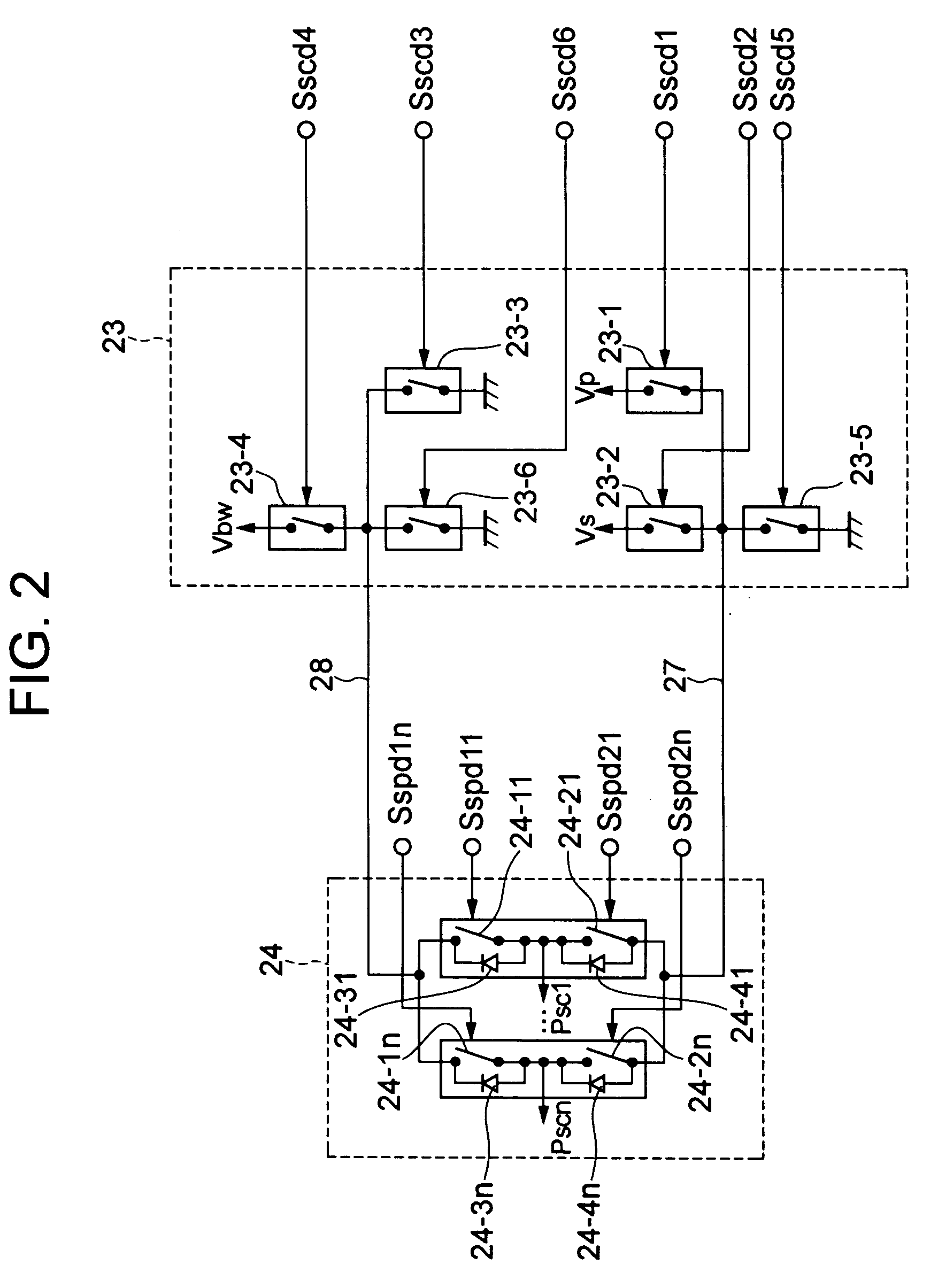

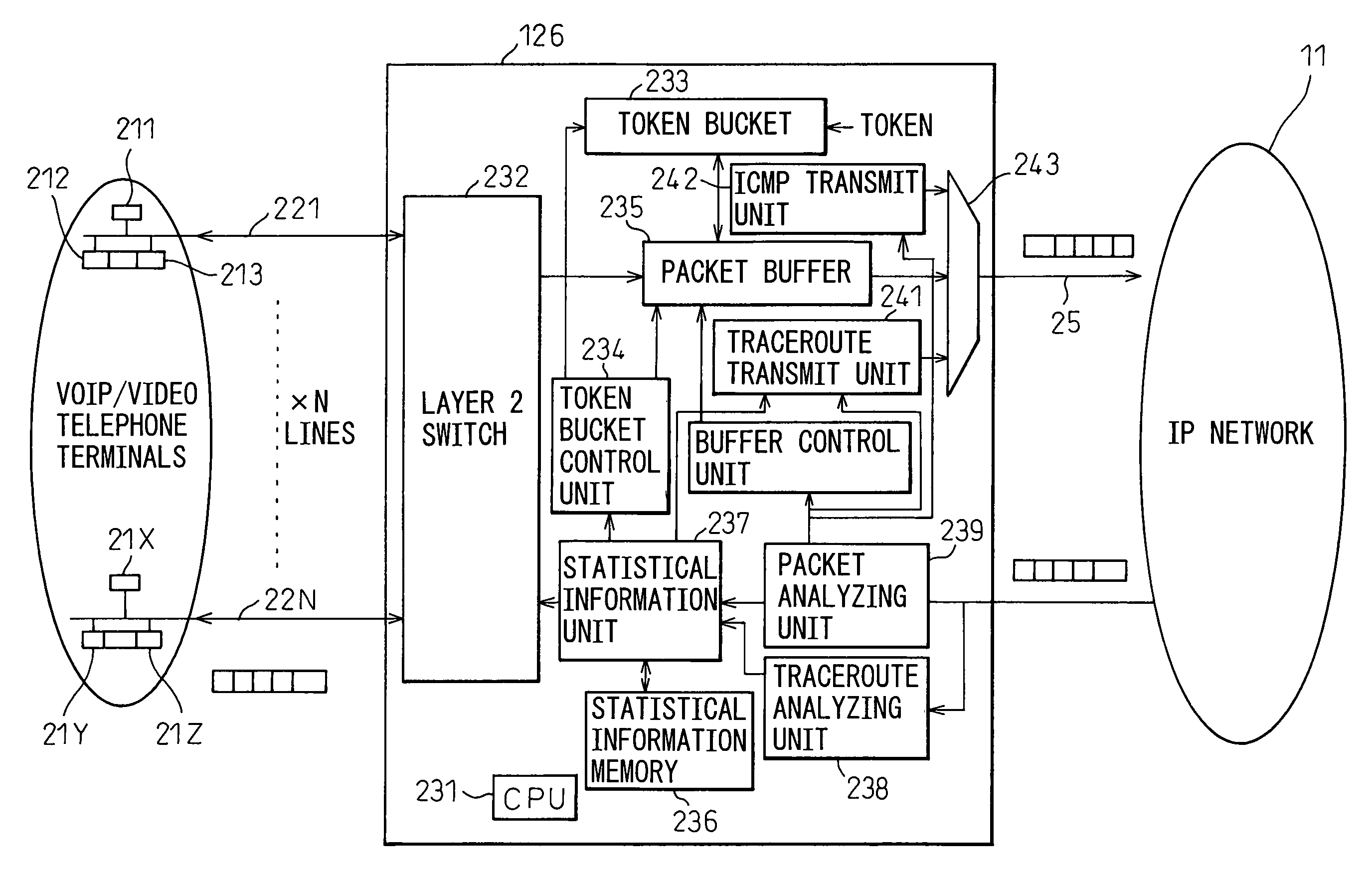

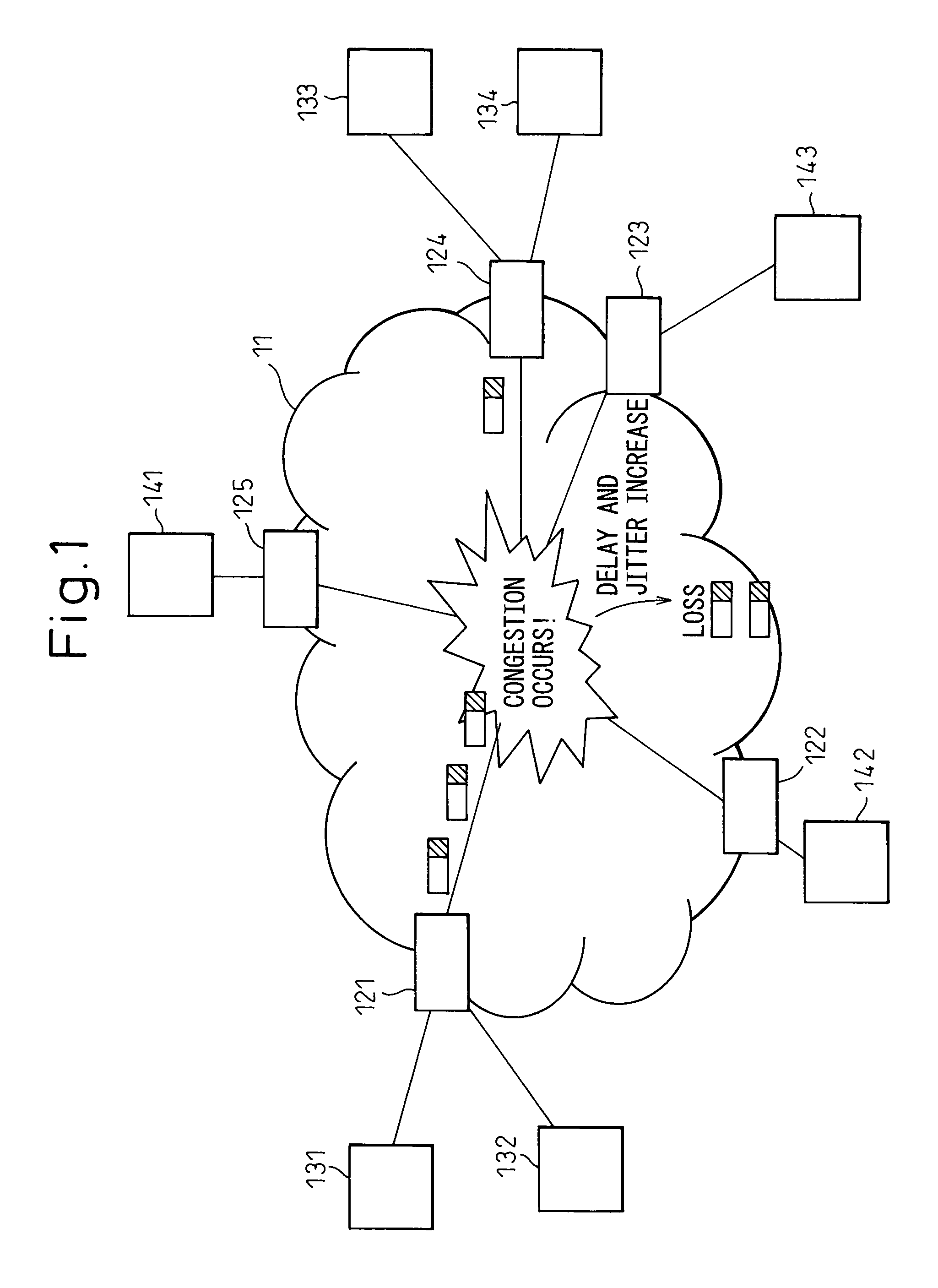

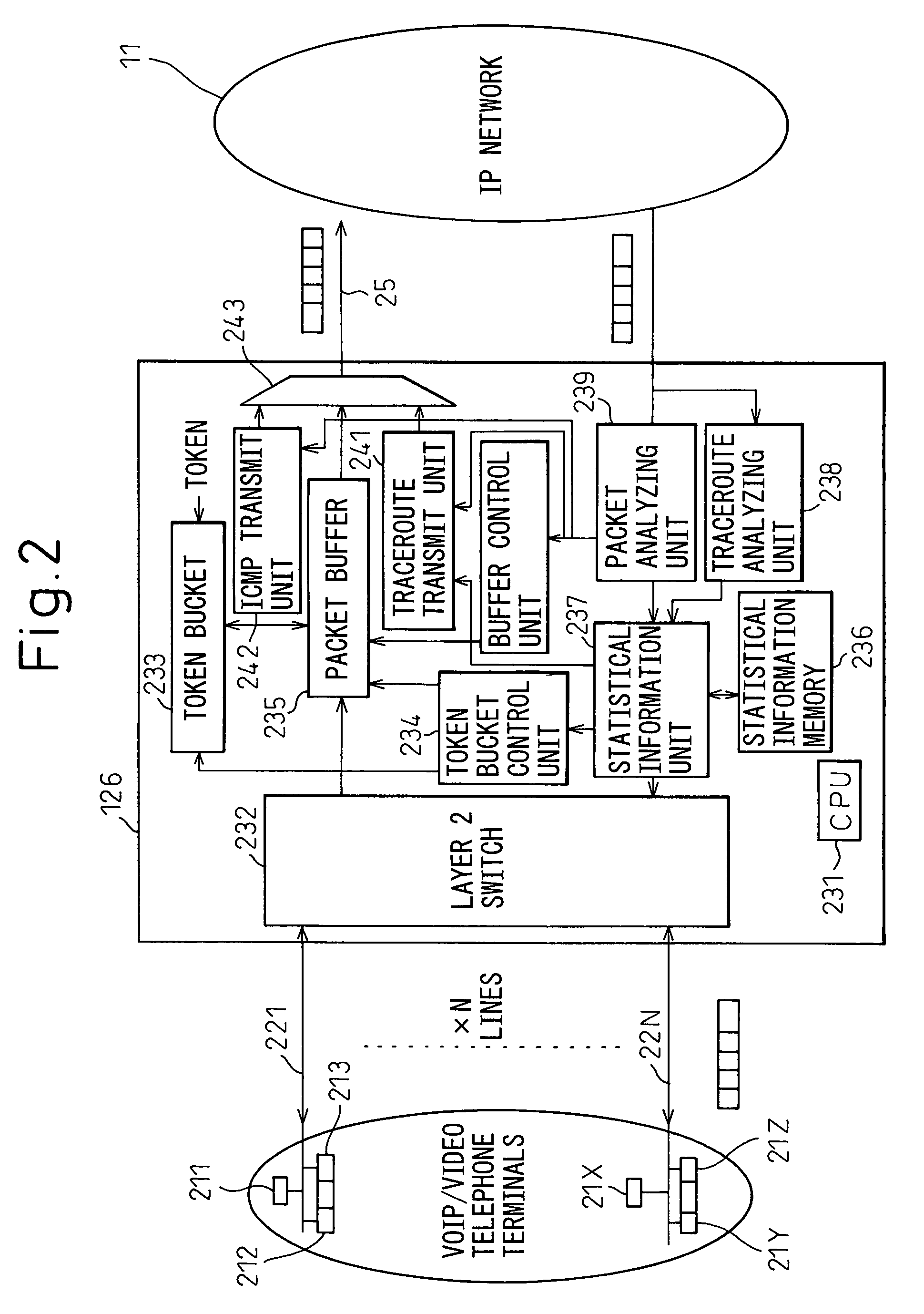

Edge switch

InactiveUS20060250962A1Avoid network congestionLimiting the amount of packetsEnergy efficient ICTError preventionPacket communicationCommunication quality

An edge switch comprises a token bucket control unit (234) which varies the amount of tokens flowing into a token bucket (233) per unit time in accordance with the congestion condition of an IP network, and the output rate of packets to be output onto a packet communication network is adjusted for each line identifier by controlling the output amount of a packet buffer, which defines the output rate of the packets to be output onto the IP network, in accordance with the amount of tokens held in the token bucket; on the other hand, a packet analyzing unit (239) comprises means for determining whether the source address of the received packet matches the address of a preregistered emergency call destination, and the token bucket control unit comprises means for further reducing, upon detection of a call initiated from an emergency call destination, the amount of tokens flowing into the token bucket for any destination address, other than the emergency call destination, that is experiencing congestion, and thereby retaining communication quality for emergency priority communication, thus achieving an edge switch that allows emergency communications to be performed with good voice quality over the IP network.

Owner:FUJITSU LTD

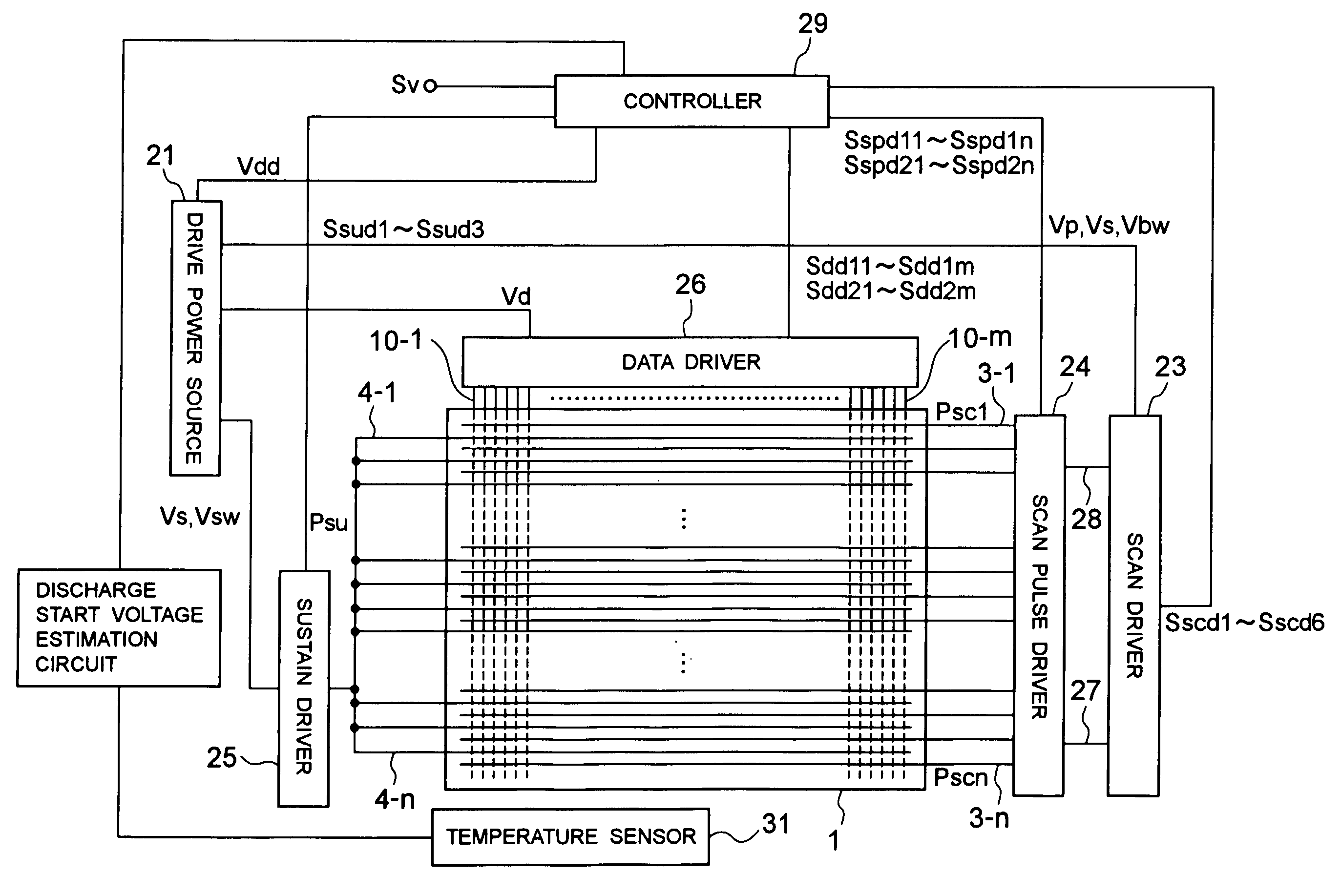

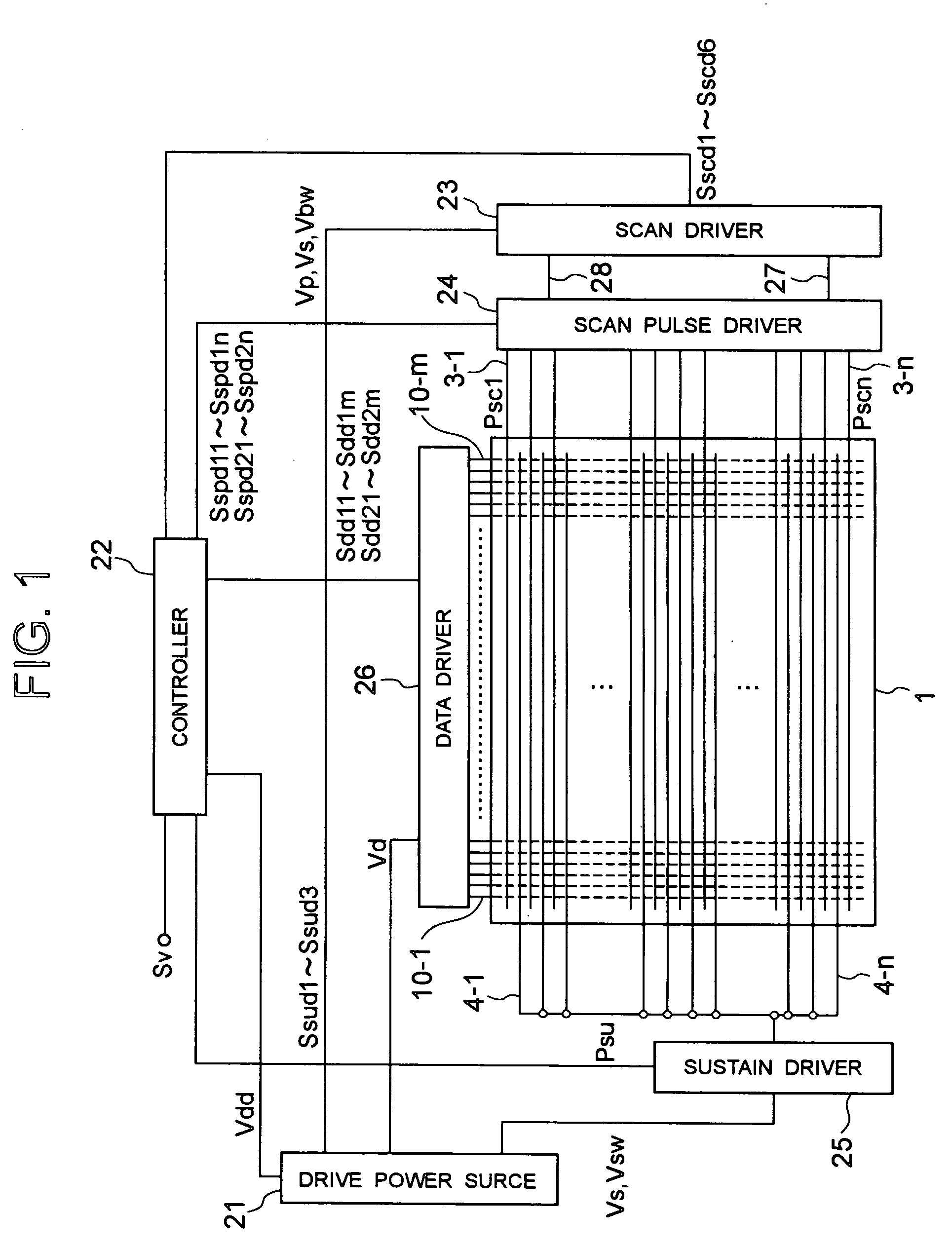

Plasma display device and method for driving the same

InactiveUS20050237276A1Increase potential differenceReduce potential differencePneumatic massageStatic indicating devicesControl signalDisplay device

When a discharge start voltage takes a normal value under the normal temperature, priming discharge starts at a time t1. In this case, at a time t3 that is later than the time t1 by a predetermined time t, a sustain driver control signal Ssud2 is raised to put a sustain electrode into the floating state to stop the priming discharge. When the discharge start voltage takes a higher value than usual under the high temperature, the priming discharge starts at a time t2. In this case, at a time t4 that is later than the time t2 by the predetermined time t, the sustain driver control signal Ssud2 is lowered to put the sustain electrode into the floating state to stop the priming discharge. With such a configuration, provided is a plasma display device capable of implementing excellent and stable display quality while maintaining constant, even if a discharge start voltage varies, the charge state in display cells after a priming period, and a drive method for such a plasma display device.

Owner:PANASONIC CORP

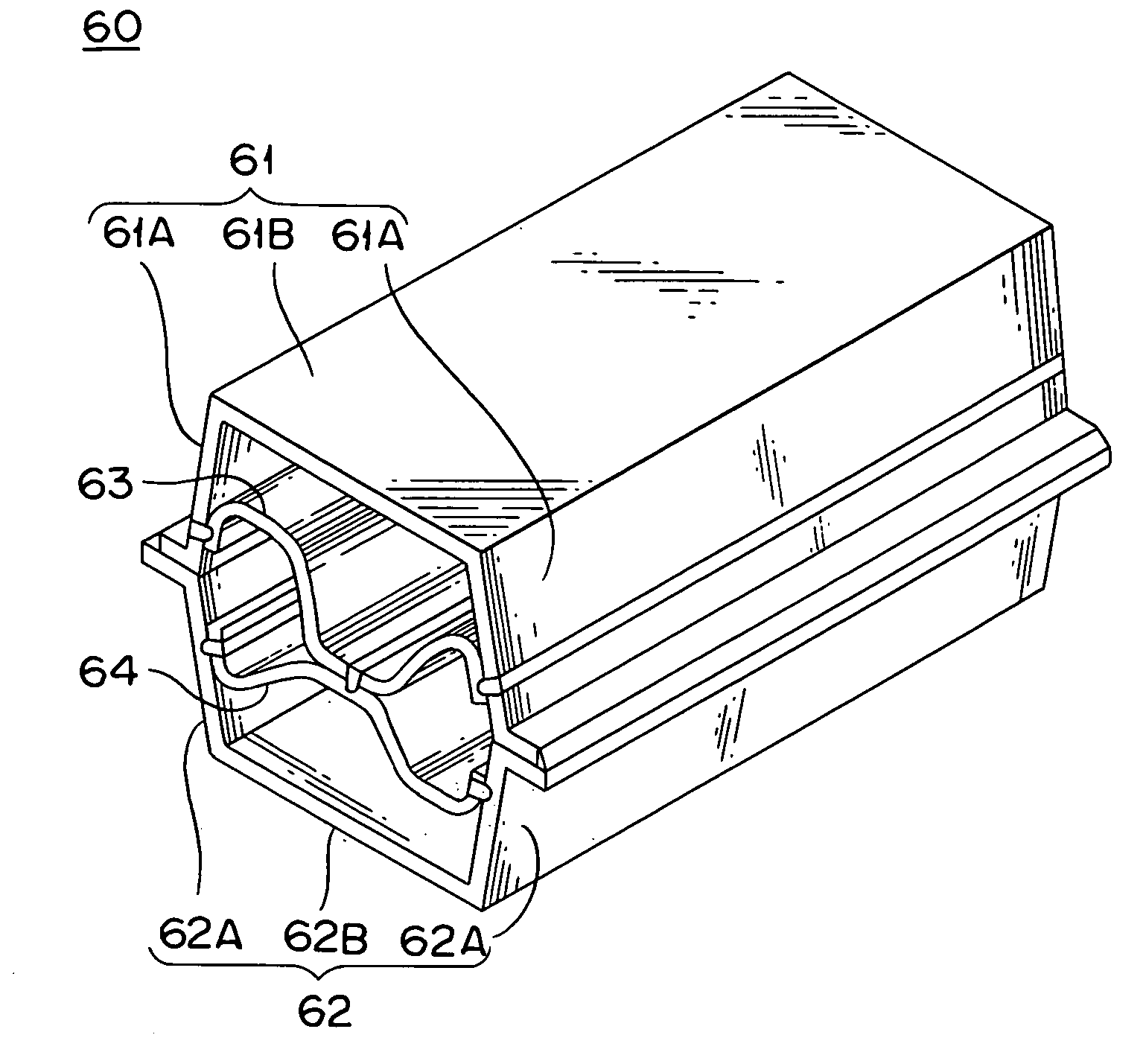

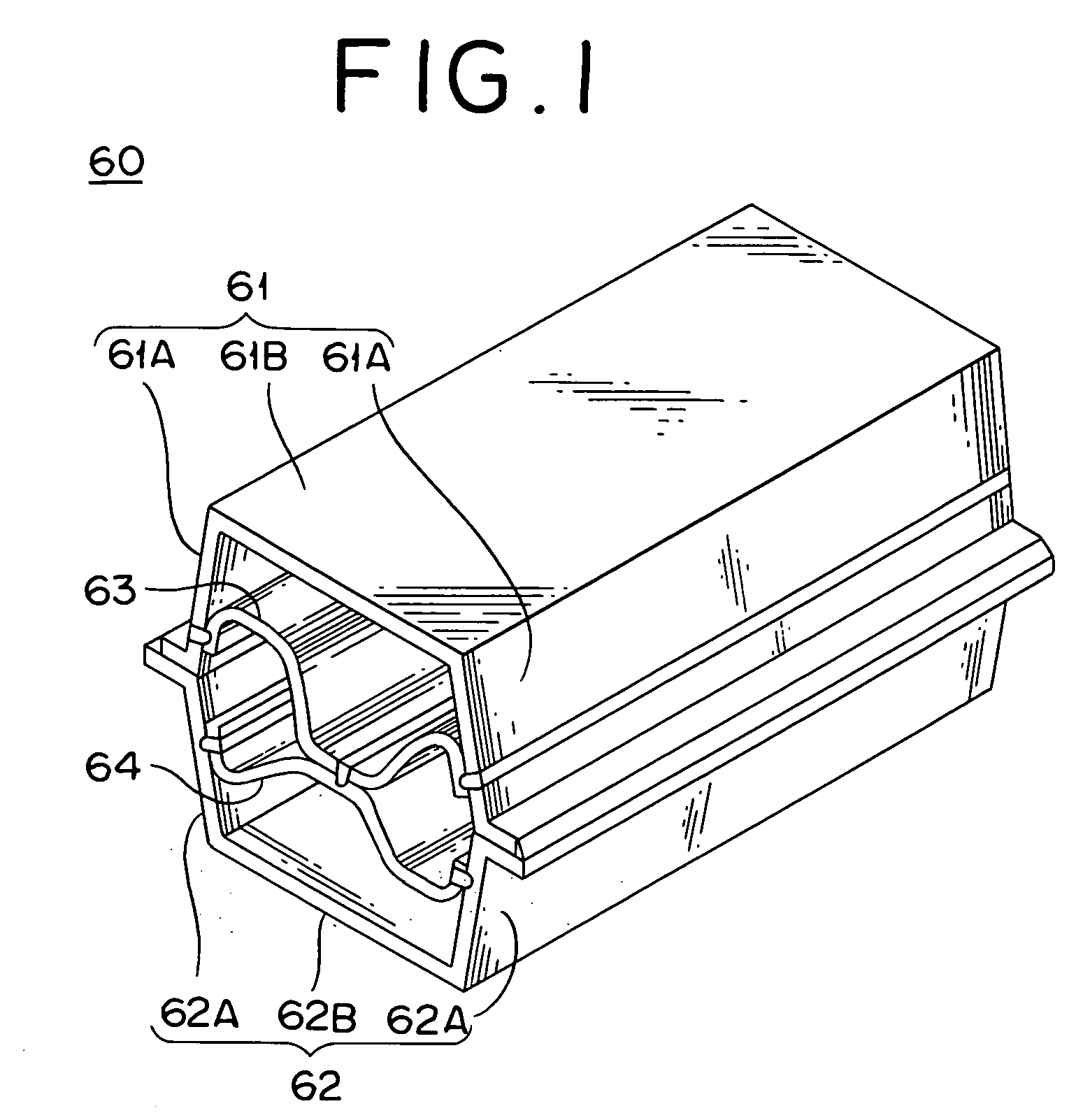

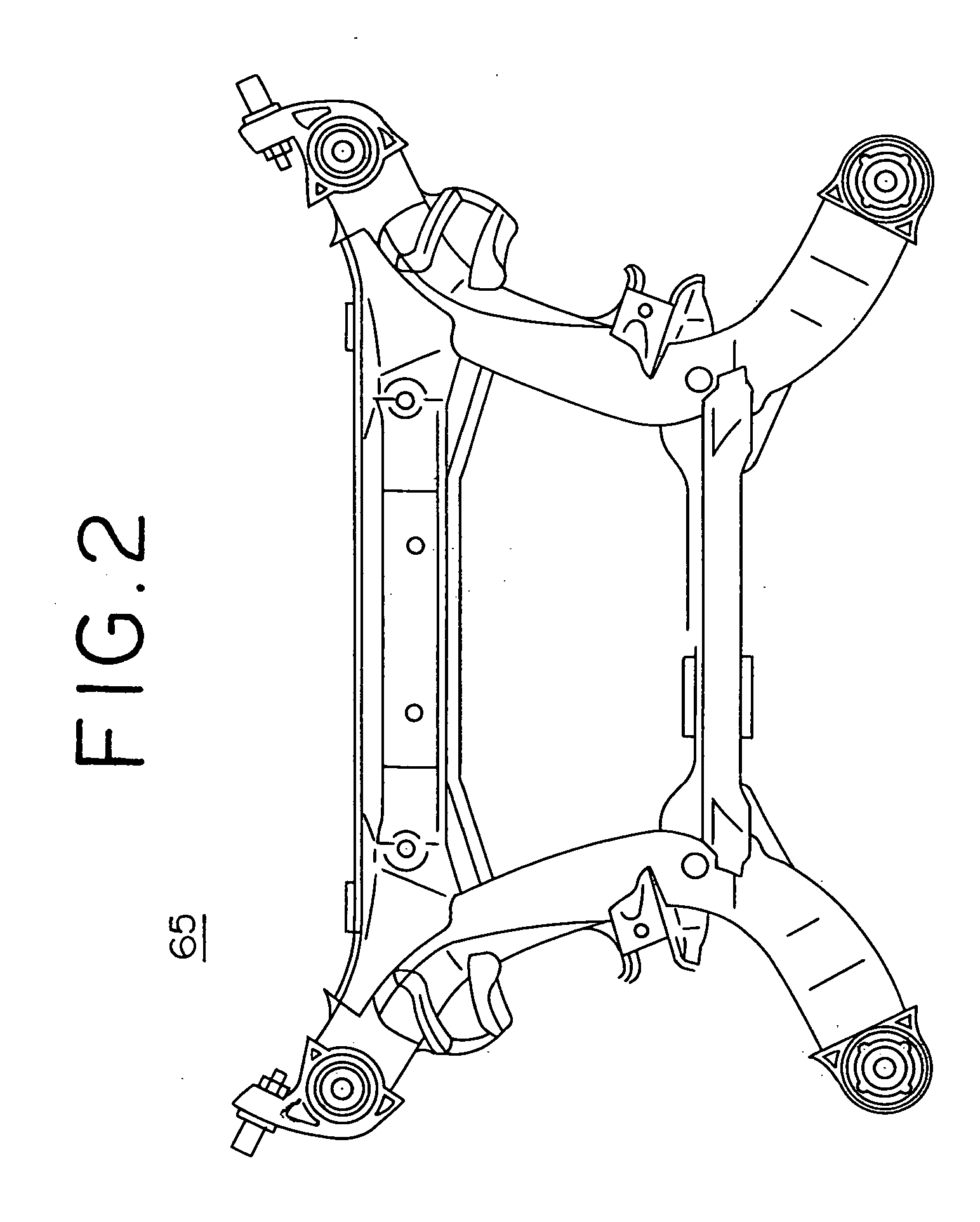

Preform, hydroforming method, and hydroformed product

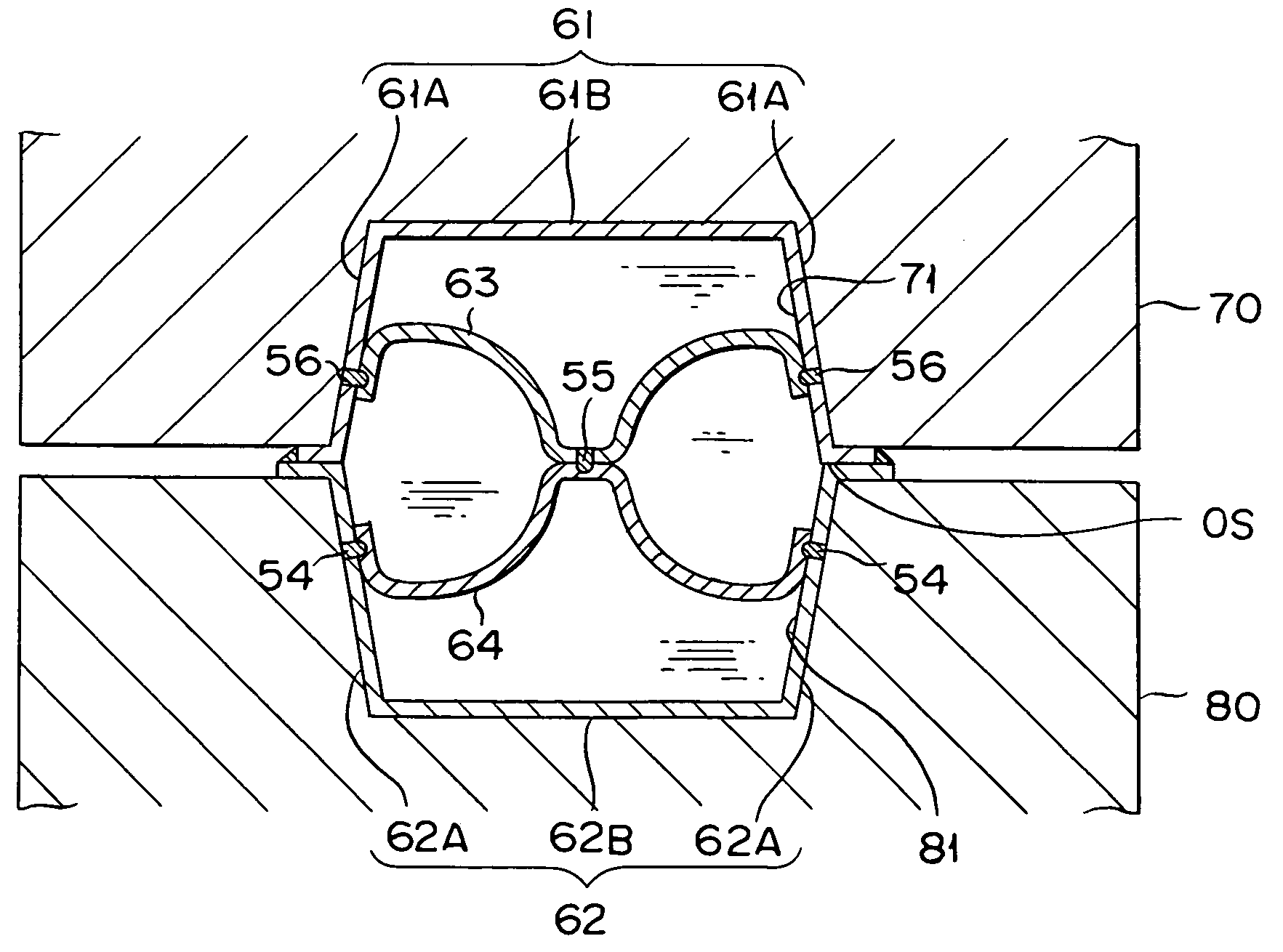

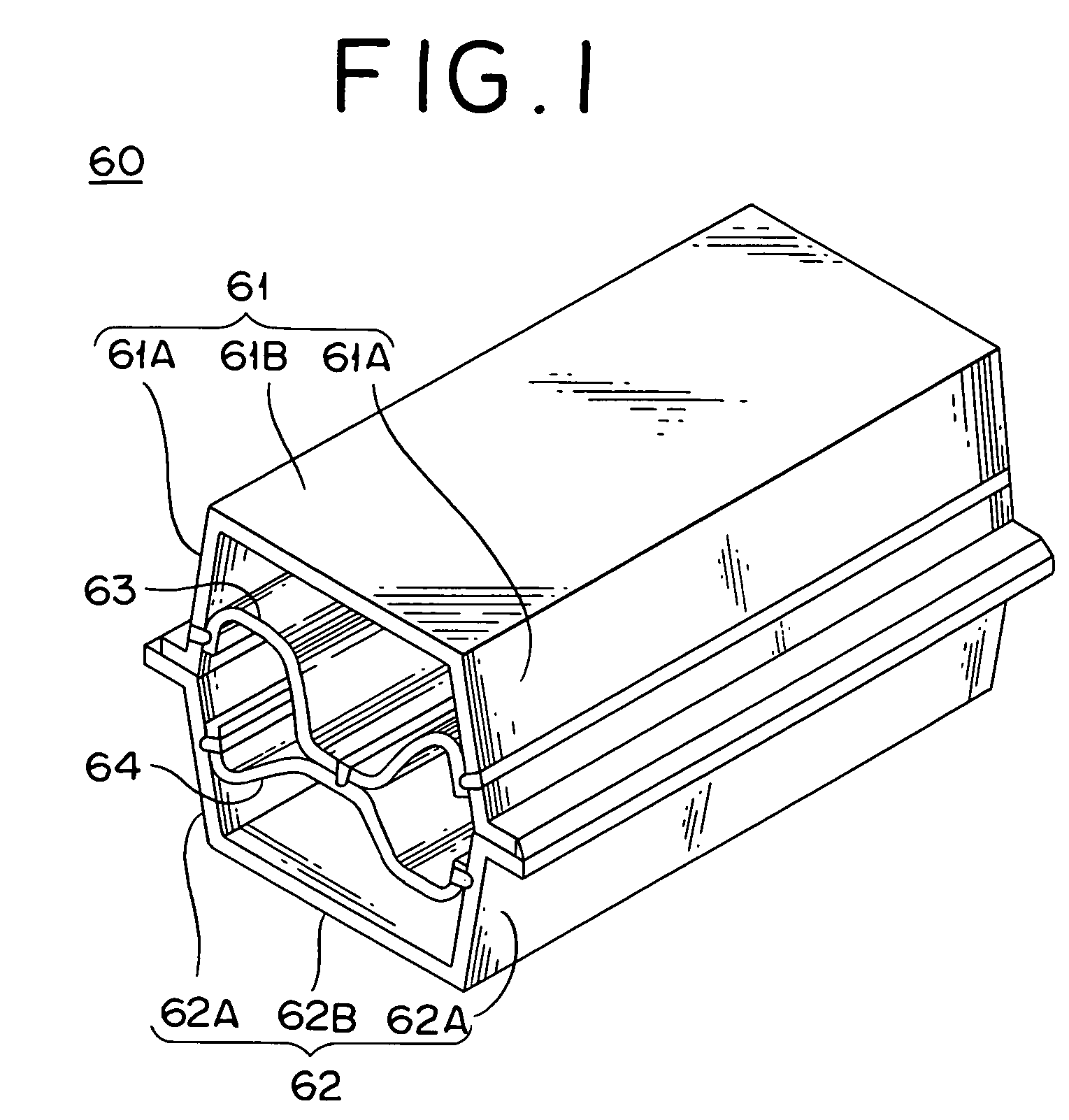

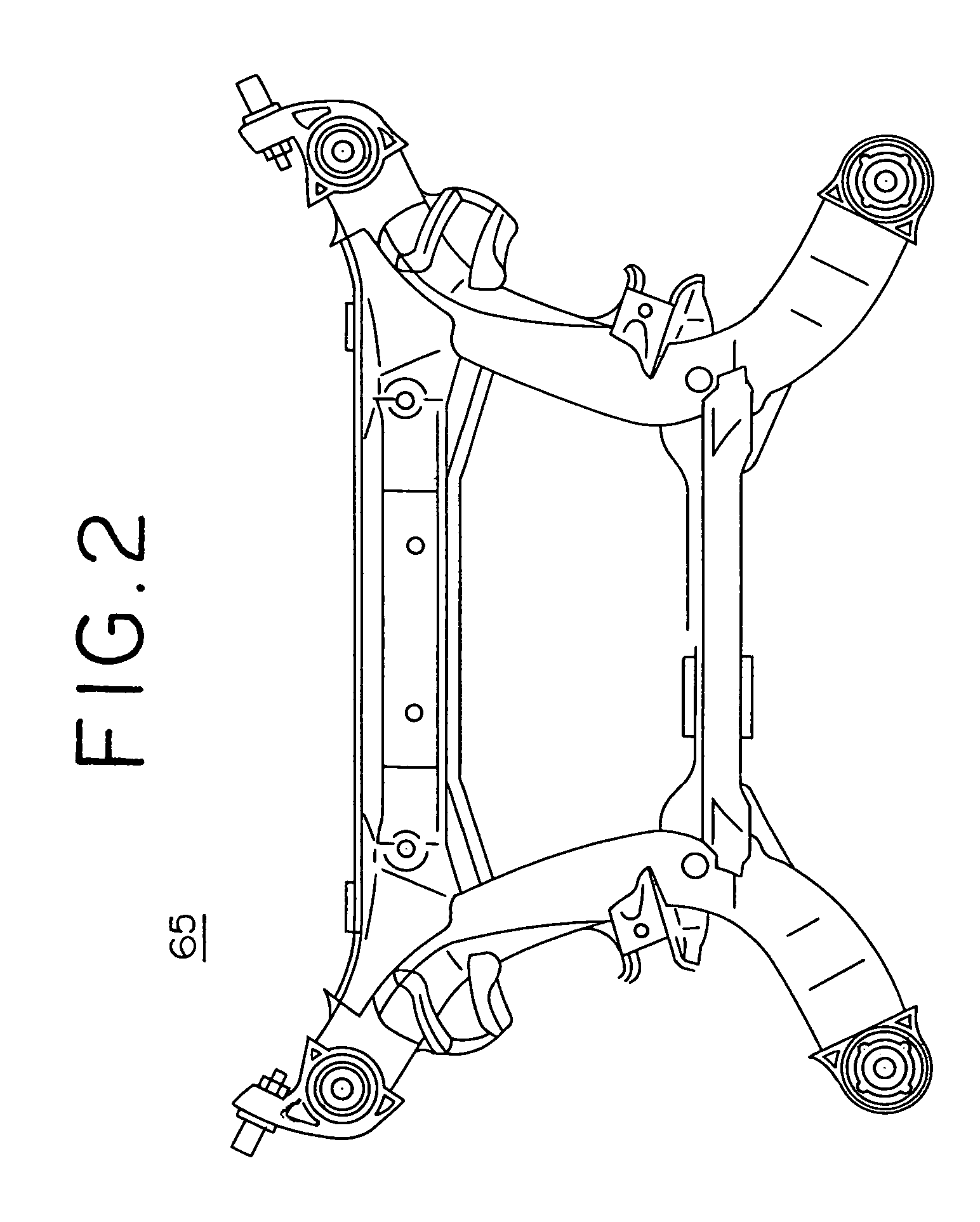

InactiveUS7406849B2Avoid fracturesExcellent and stable qualityVehicle seatsLoad-supporting pillarsEngineeringHydroforming

A preform with edges overlapped and jointed each other and first and second outer members for forming outer surfaces of a hydroformed product, and reinforcement members that are jointed to the first and second outer members to form reinforcement ribs that divide a hollow cross section of the outer surfaces, the reinforcement members having dimensions capable of suppressing elongation in a tensile direction due to a tensile force that develops during hydroforming.

Owner:NISSAN MOTOR CO LTD

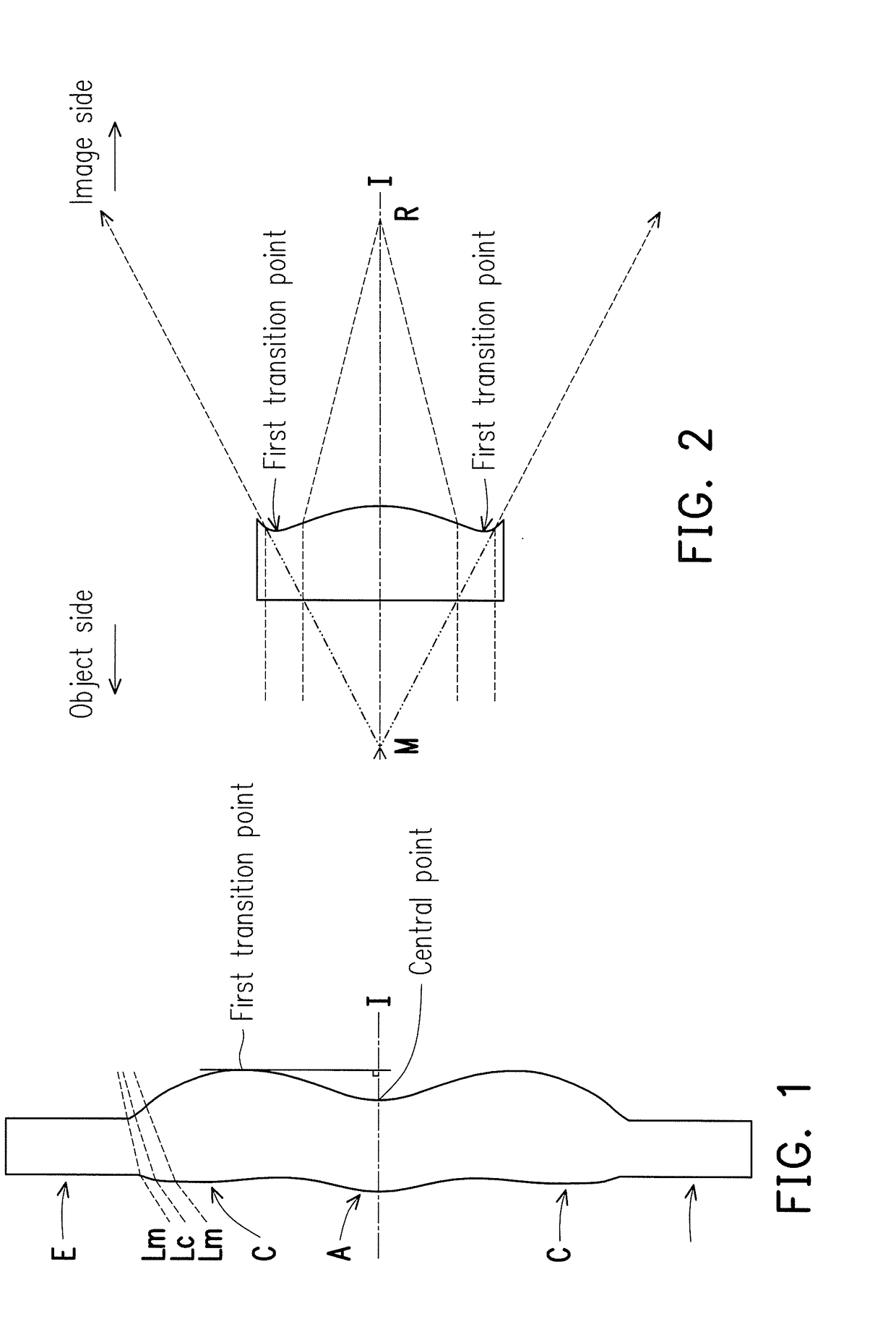

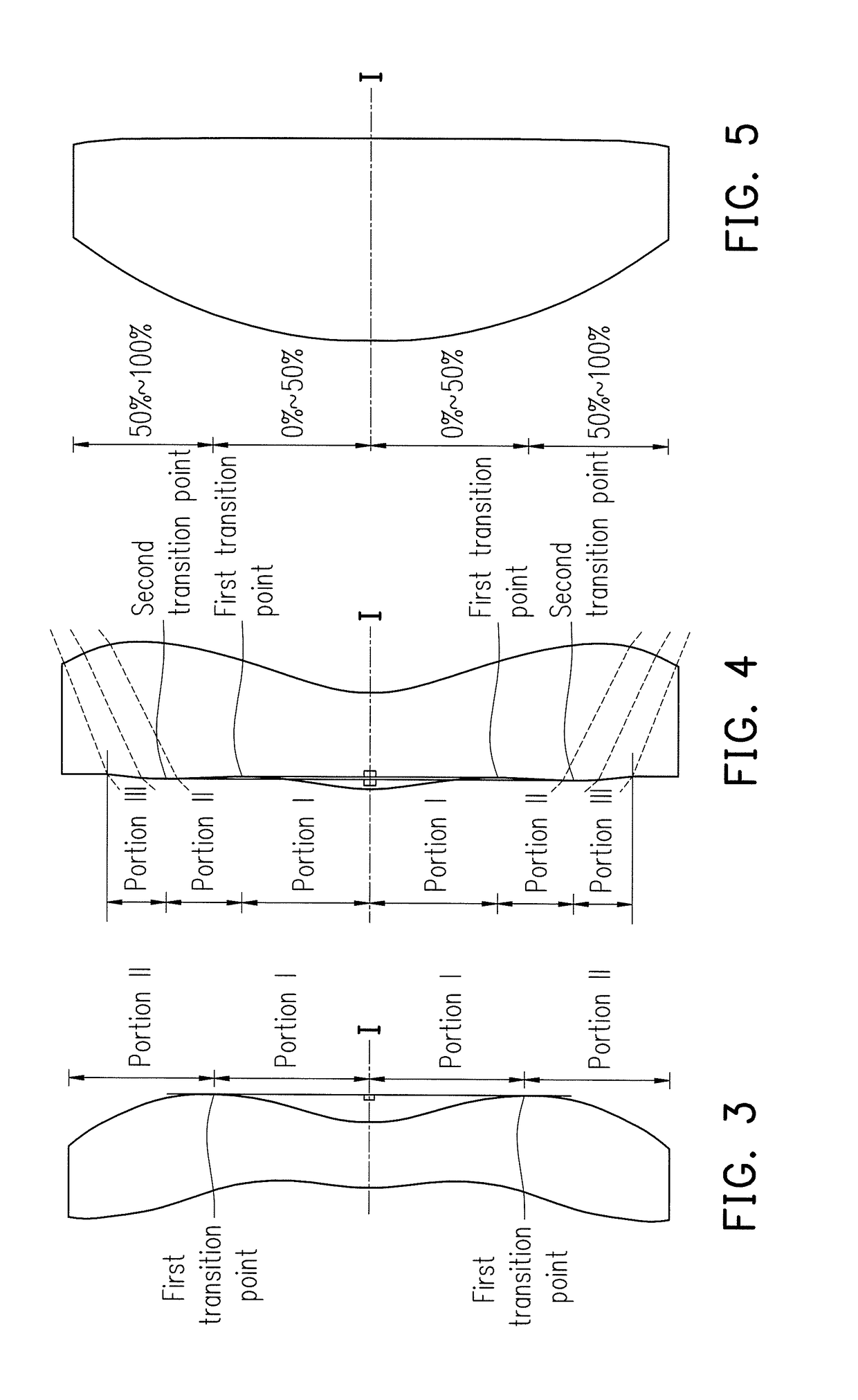

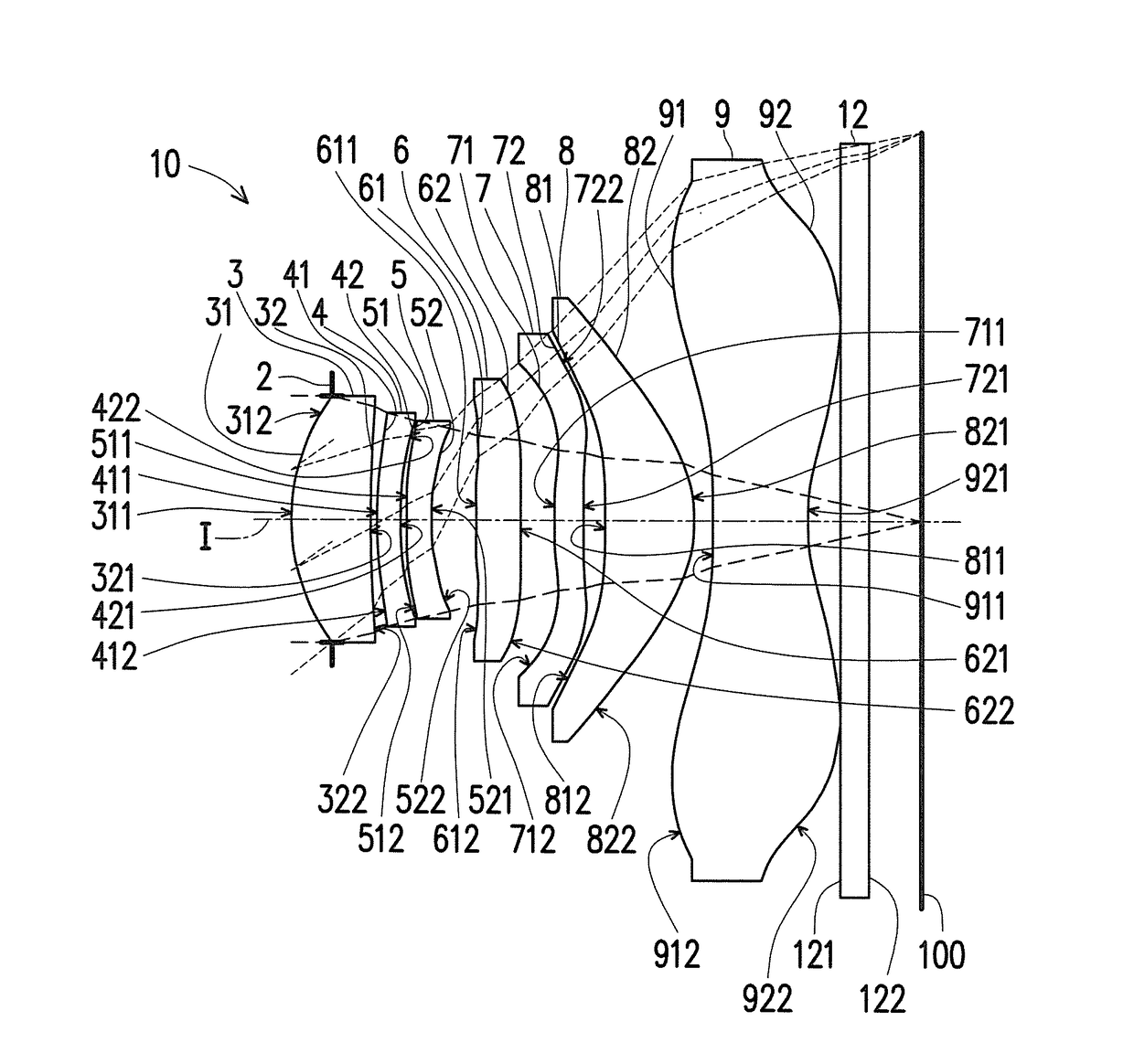

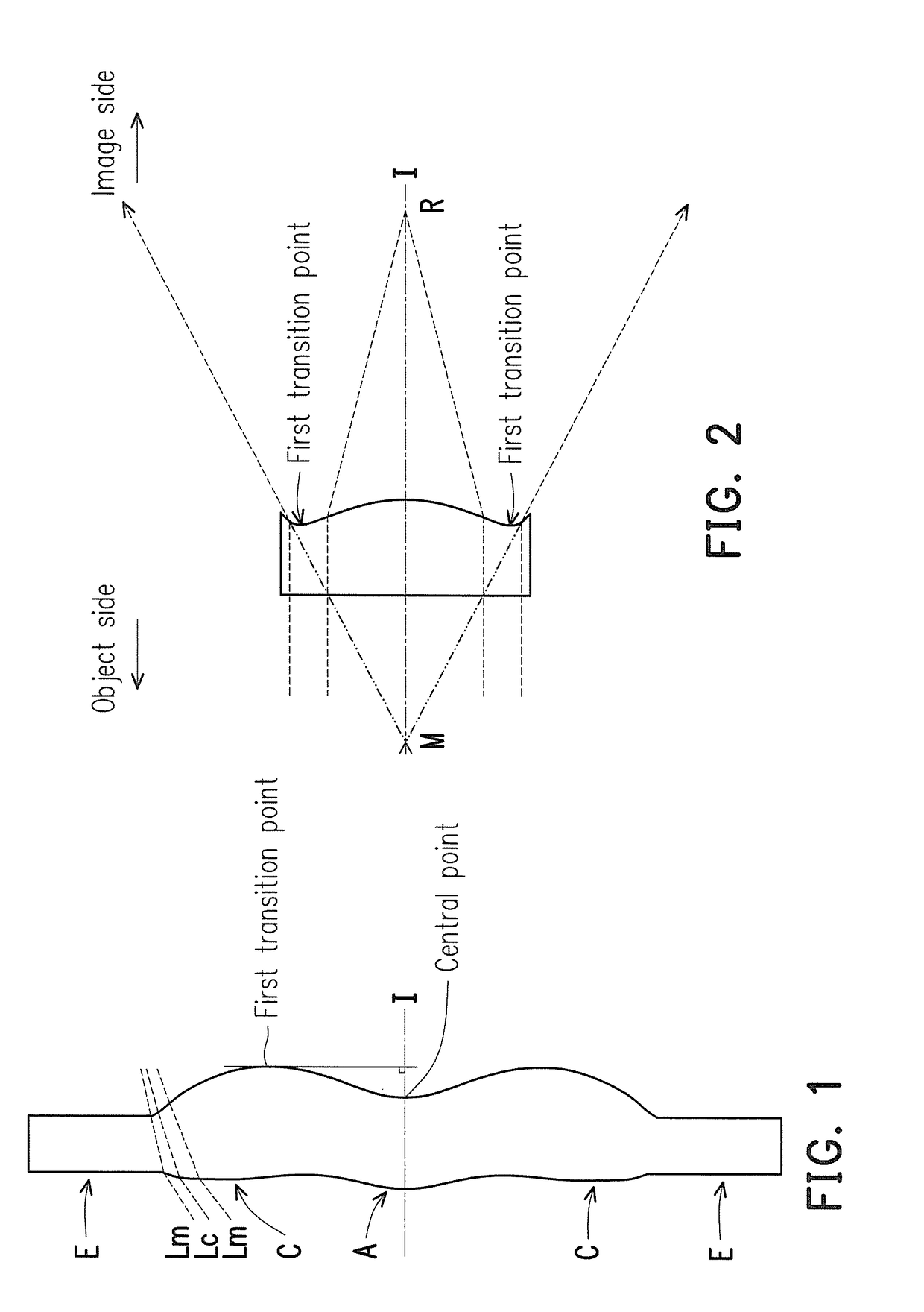

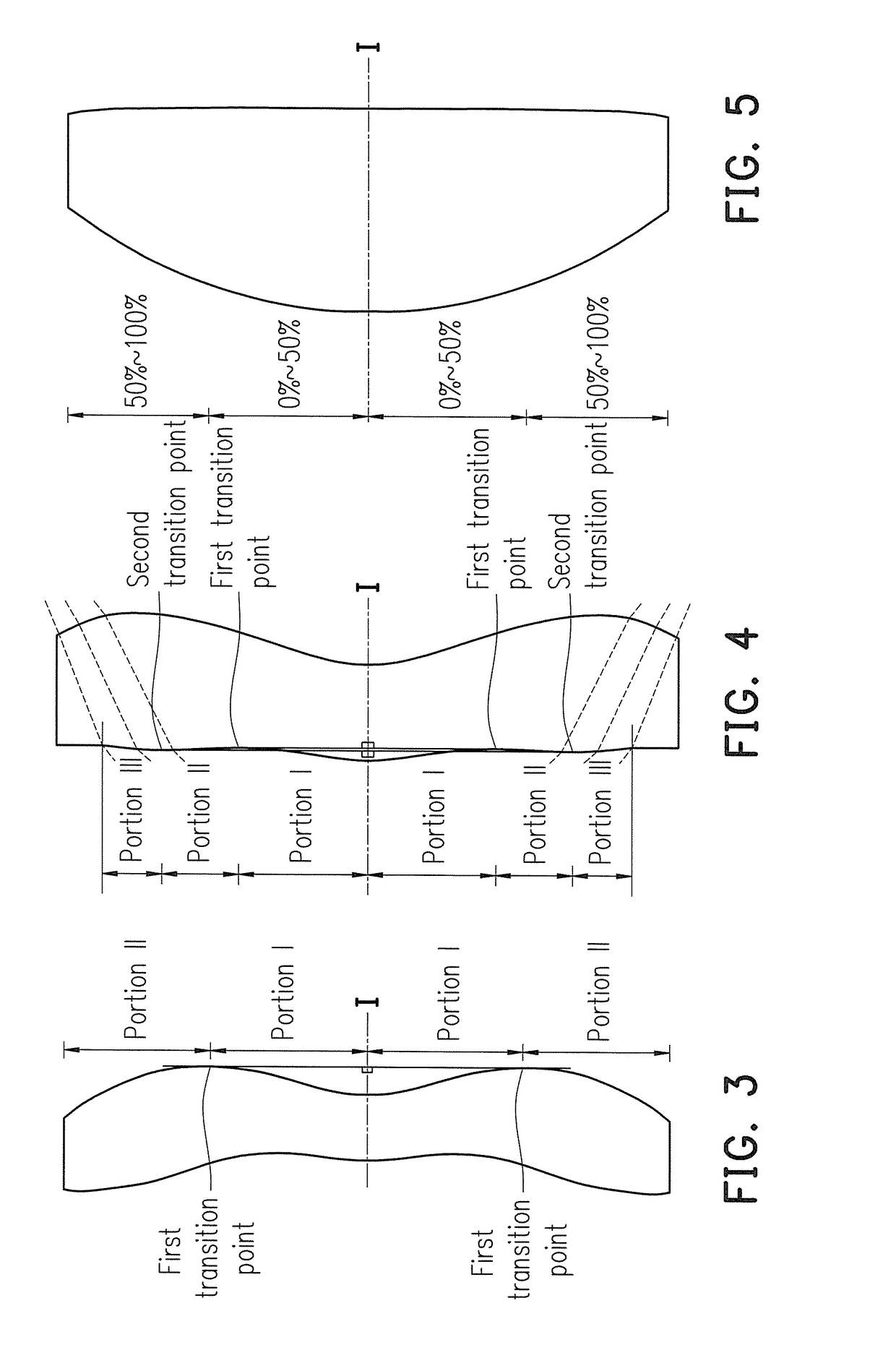

Optical imaging lens

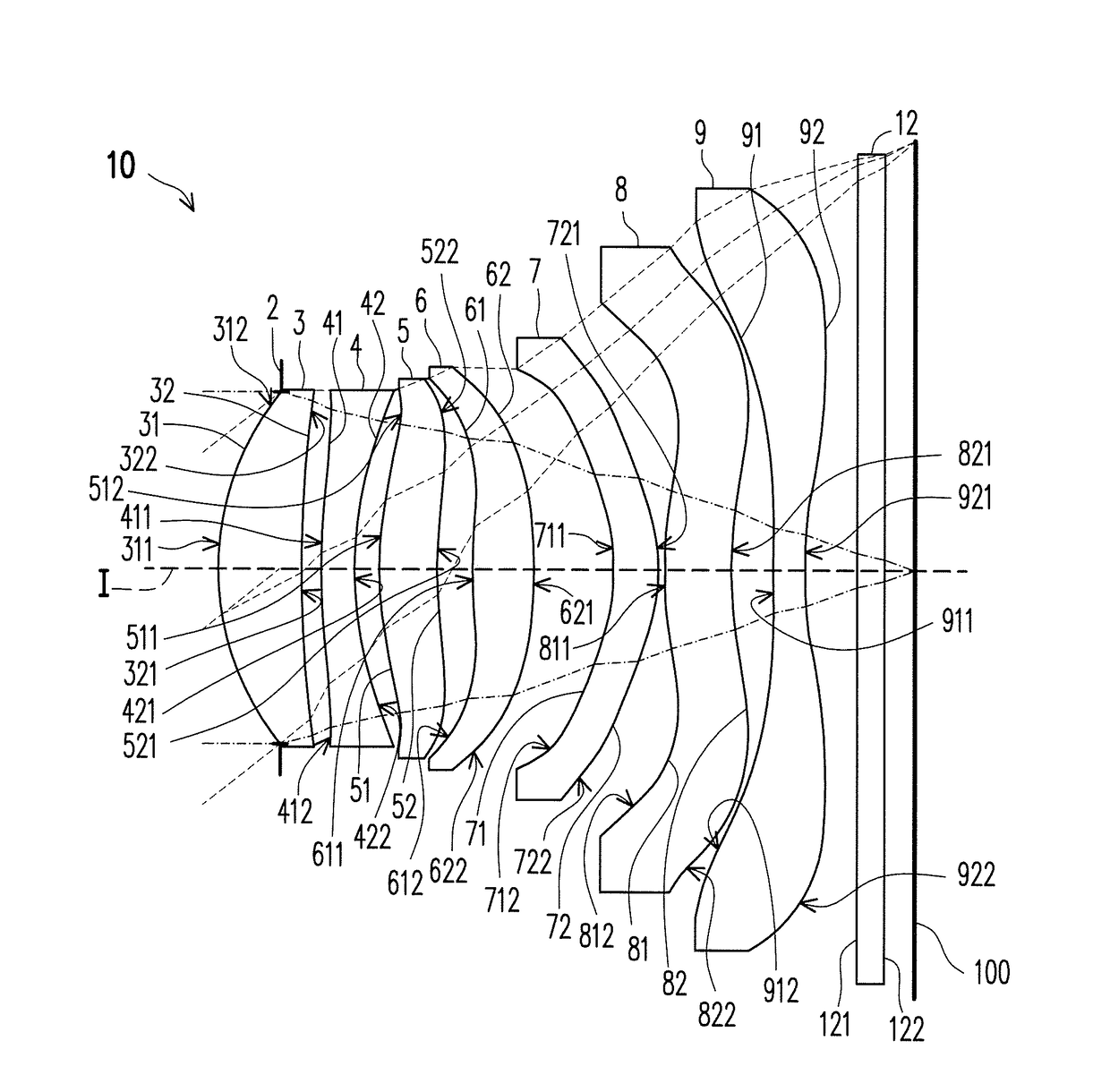

ActiveUS20180188482A1Good and stable image qualityShortened total lens lengthLensMountingsCamera lensOptical axis

An optical imaging lens includes a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a seventh lens element arranged in order from an object side to an image side along an optical axis. Each lens element has an object-side surface and an image-side surface. The optical imaging lens satisfies: V4+V5+V6+V7≤175.00, wherein V4 is an Abbe number of the fourth lens element, V5 is an Abbe number of the fifth lens element, V6 is an Abbe number of the sixth lens element, and V7 is an Abbe number of the seventh lens element.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Optical imaging lens

ActiveUS20180188486A1Good and stable image qualityShorten lens lengthOptical elementsOptical axisOptoelectronics

An optical imaging lens includes a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a seventh lens element arranged in order from an object side to an image side along an optical axis. Each lens element has an object-side surface and an image-side surface. The first lens element has positive refracting power, and the image-side surface of the first lens element has a concave portion in a vicinity of a periphery. The third lens element has negative refracting power, and the image-side surface of the third lens element has a concave portion in a vicinity of a periphery. At least one of the object-side surface and the image-side surface of the fourth lens element is aspheric surface, and at least one of the object-side surface and the image-side surface of the fifth lens element is aspheric surface. The sixth lens element has positive refracting power, and the image-side surface of the seventh lens element has a concave portion in a vicinity of the optical axis.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Preform, hydroforming method, and hydroformed product

InactiveUS20060066133A1Avoid fracturesStable and excellent strength qualityVehicle seatsLoad-supporting pillarsEngineeringHydroforming

A preform with edges overlapped and jointed each other and first and second outer members for forming outer surfaces of a hydroformed product, and reinforcement members that are jointed to the first and second outer members to form reinforcement ribs that divide a hollow cross section of the outer surfaces, the reinforcement members having dimensions capable of suppressing elongation in a tensile direction due to a tensile force that develops during hydroforming.

Owner:NISSAN MOTOR CO LTD

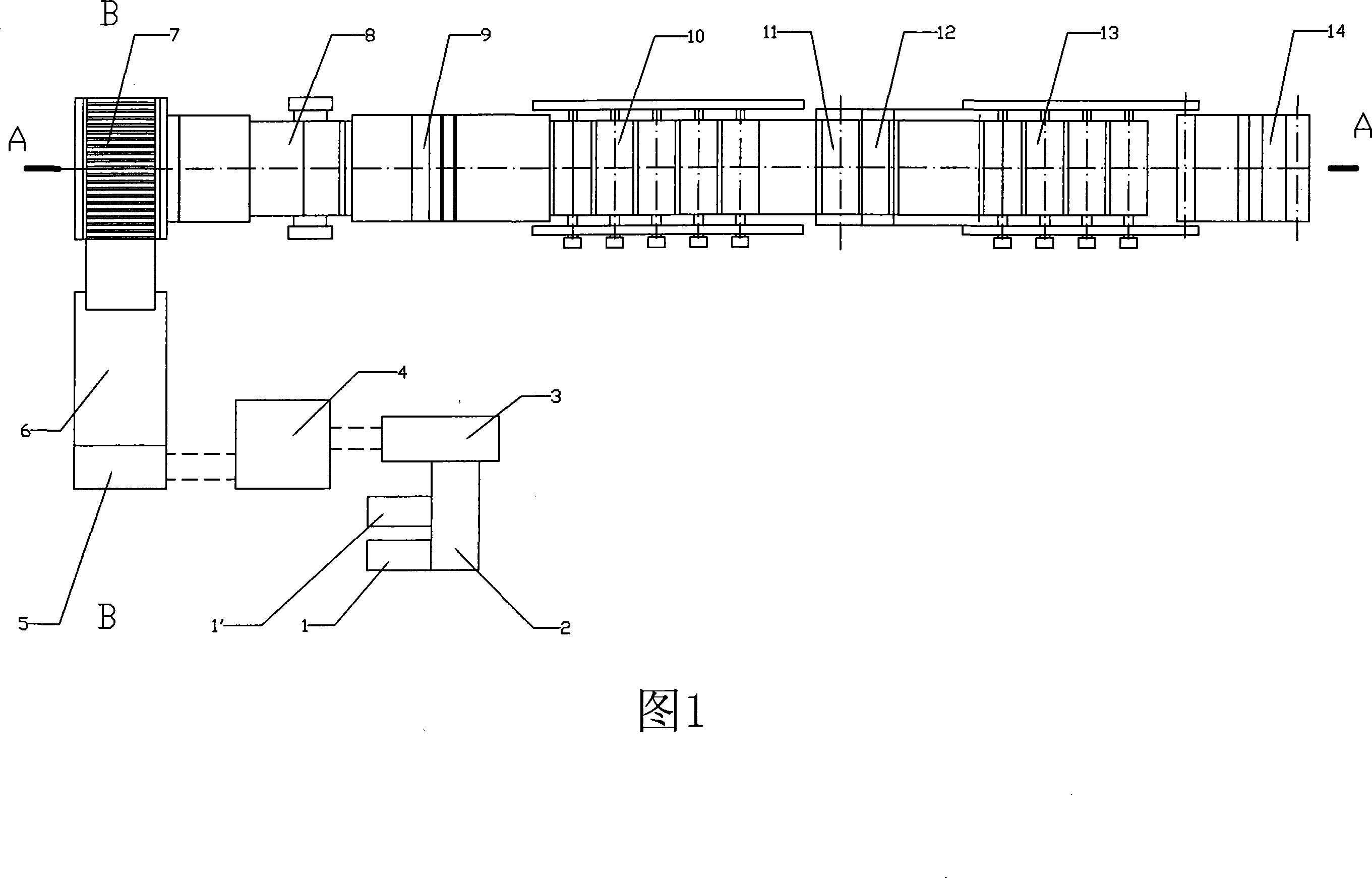

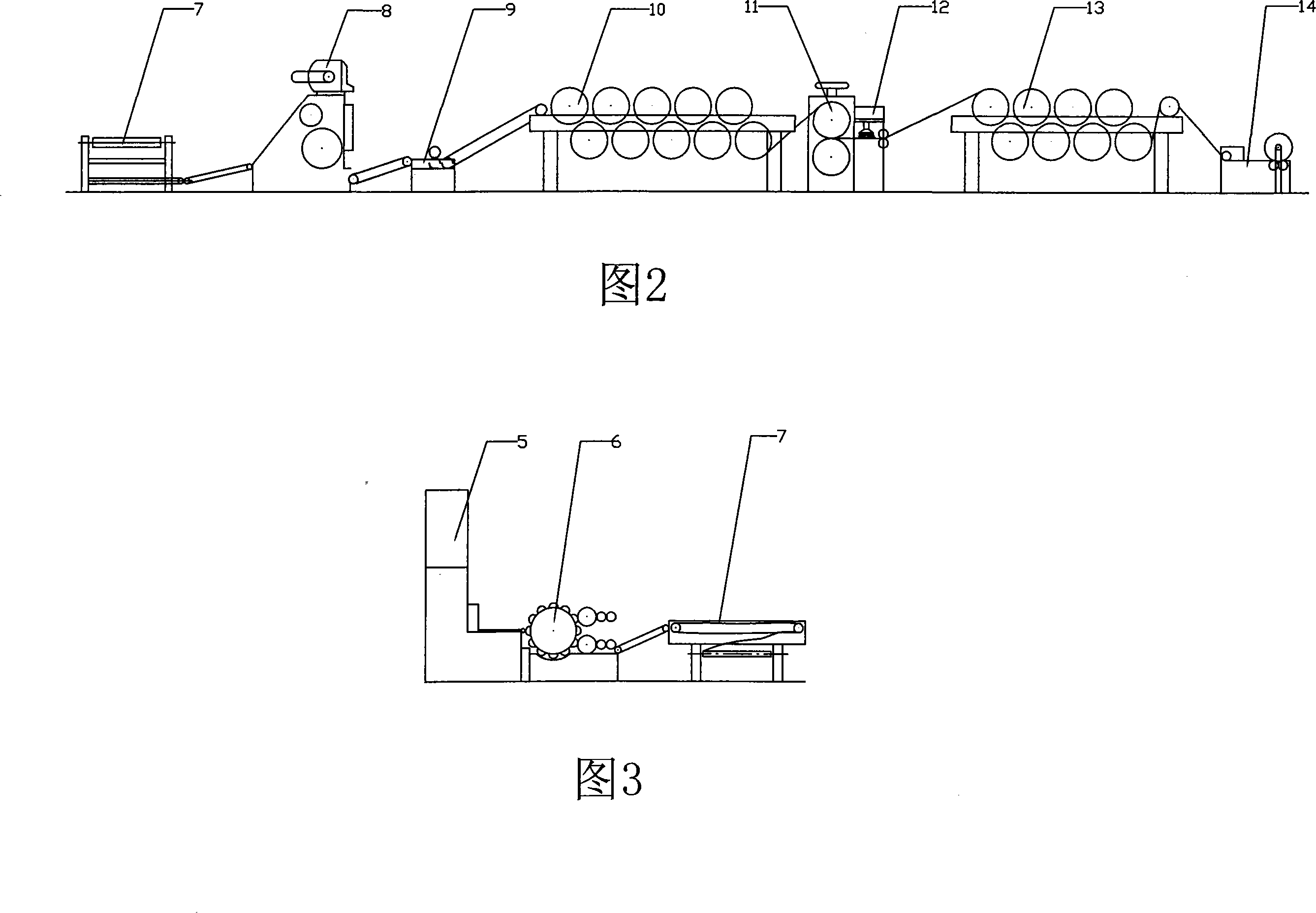

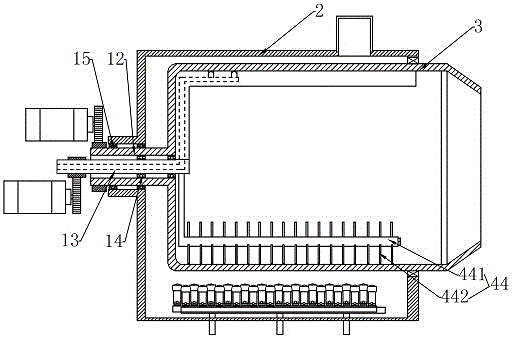

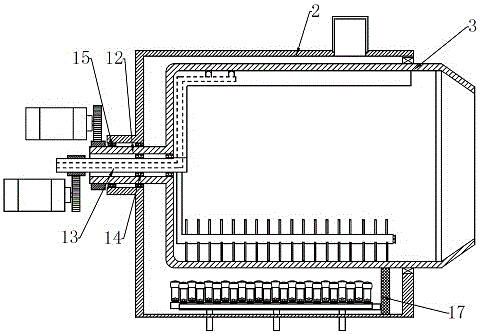

Device for preparing environment-friendly type bast fiber film

ActiveCN101215786ARun at high speedEasy to debugLap forming devicesPlant protective coveringsSpray coatingVolumetric Mass Density

The invention discloses an environment-friendly type bast fiber film preparation device, which comprises two feeding machines, a feed mixer, a crude opening machine, a fine opening machine, a vibrating air pressure bast feeding box, a carding machine, a mechanical cross lapper, an air-lay machine, an impregnator, a drying can type pre-drying pit, an air-pressure double-roller planishing mill, a surface spraying coating machine, a drying can type dying setting machine, a drafting side cut lap former and the other operation unit machines. Each unit-air conditioning adopts variable-frequency control and a synchronizer to control electric appliances, and each unit-air conditioning can be singly operated in high speed, and can be interlocked to operate with complete equipment. The invention has the advantages that fibrilia is delivered by an airflow pipeline on the crude opening machine, and between the crude opening machine and the carding machine, and the supply of raw material is continuous, net is combined in two times through a machine to pave net and airflow to form net, bast fiber film net has little density, even strength and stable quality, even coating layers are coated and sprayed on double faces of bast fiber film, and bast fiber film with different functions and usages can be made, continuous and stable full-automatic production of bast fiber film can be achieved.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

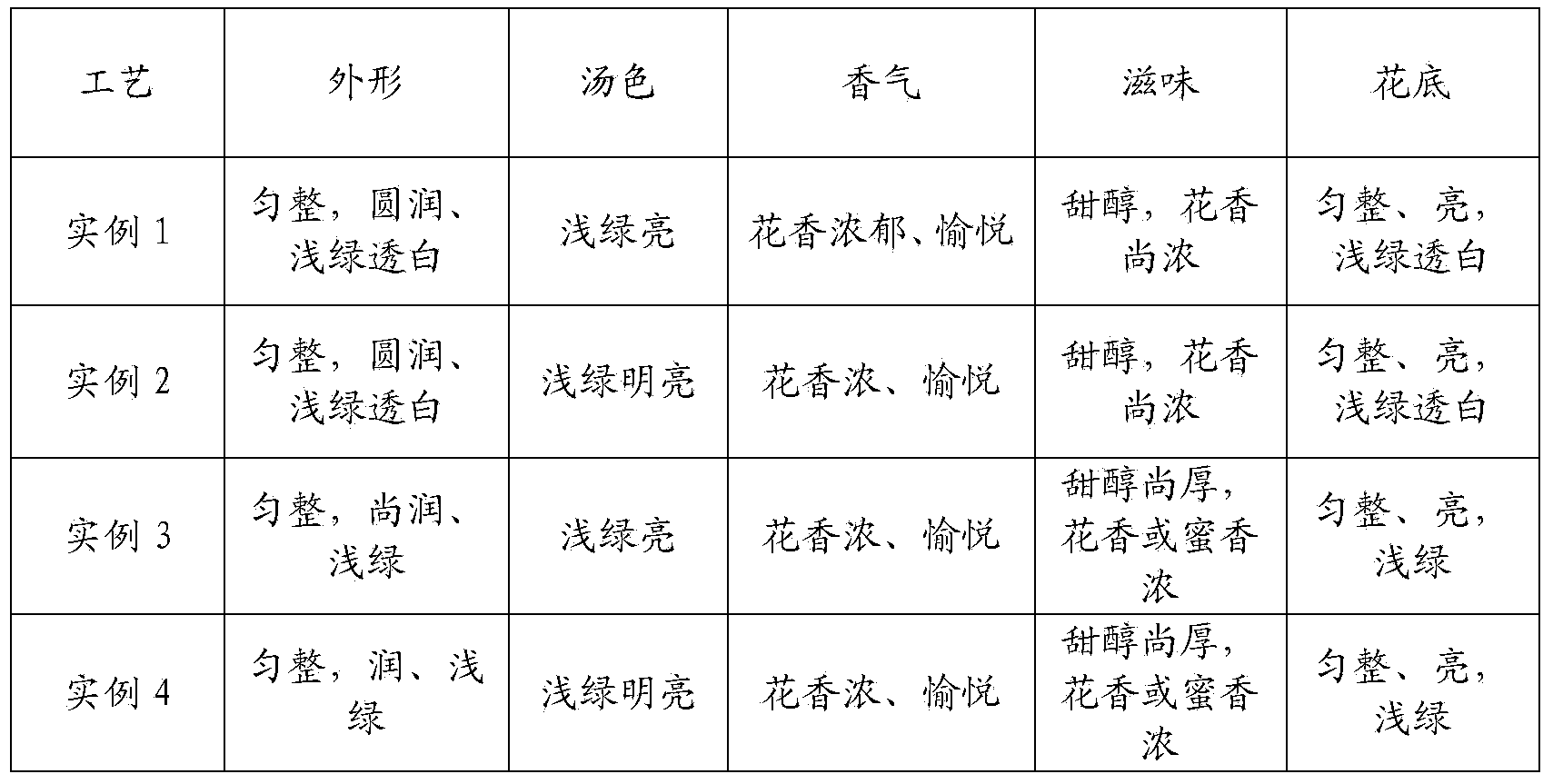

Processing method for tea flowers

The invention relates to a processing method for tea flowers. The processing method comprises the following steps: picking the tea flowers, withering, carrying out fixation, drying and packaging. According to the method, a microwave water removing machine is utilized for rapidly finish fixation in short time; meanwhile, in a fixation process, a lot of water molecules are escaped and evaporated from the tea flowers so as to realize the primary drying aim; the color, the flavor, the shape and the taste of the fresh tea flowers can keep unchanged to the greatest extent and effective substances are kept to the greatest extent; the high-aroma and the high-quality tea flowers are prepared.

Owner:GUANGXI GUILIN TEA RES INST

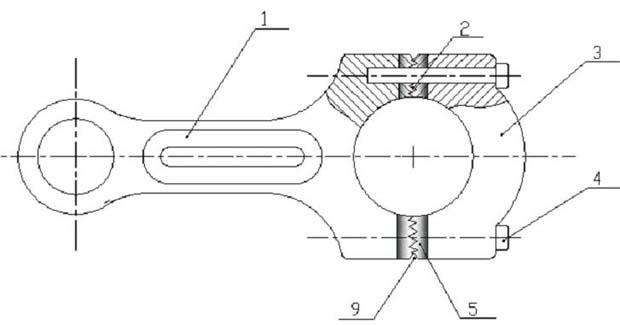

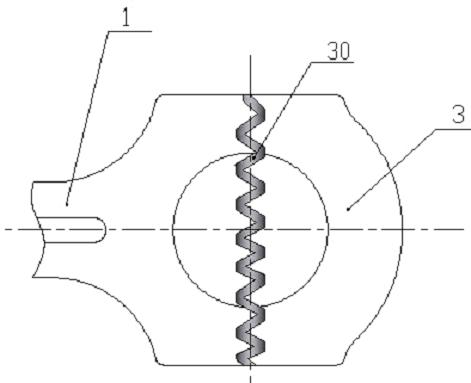

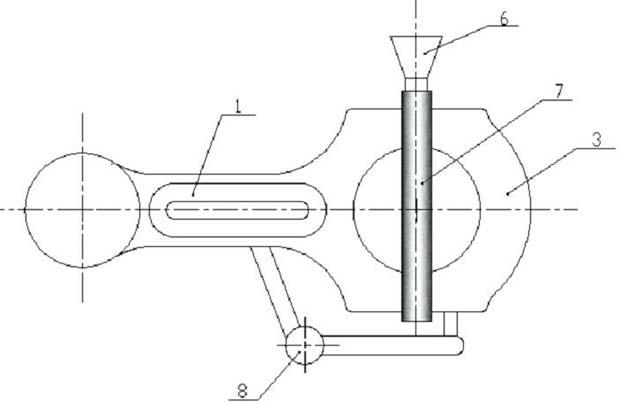

Manufacturing method of composite double-metal cracking connecting rod

InactiveCN102626777ABroaden your optionsGuarantee the performance of the main bodyConnecting rodsShaftsHigh loadMechanical engineering

The invention relates to a manufacturing method of a composite double-metal cracking connecting rod. The method disclosed by the embodiment of the invention comprises the following steps of: arranging a movable isolating plate at a big head part of a connecting rod cavity; dividing the mold cavity into two independent parts; firstly casting a connecting rod body and a connecting rod cover by adopting materials of a connecting rod main body; when large parts of the connecting rod body and the connecting rod cover are solidified, pulling out the isolating plate from the mold cavity, then injecting materials for cracking areas into the cavity formed after the isolating plate is pulled, and forming a composite double-metal casting piece by combining two materials in a metallurgical manner; and then finishing cracking separation for the connecting rod body and the connecting rod cover along preset cracking surfaces by adopting cracking equipment, and carrying out positioning and accurate assembly by utilizing a meshed intertongue structure on the two cracking surfaces. The manufacturing method of the composite double-metal cracking connecting rod has the advantages that the material selection range of the cracking connecting rod is expanded, the process is simple and feasible, the cost is low, and the assembling accuracy of the connecting rod is high; the technology is also suitable for manufacture of high-power engine connecting rods so as to meet the requirement for bearing high-load and large-torque connecting rods; and the process method has a wide application prospect.

Owner:JIANGSU UNIV

Method for industrially planting pleurotus eryngii by utilizing mulberry wood chips

InactiveCN102440148AExcellent and stable qualityReduce procurement difficultiesHorticultureFertilizer mixturesSawdustPleurotus

The invention discloses a method for industrially planting pleurotus eryngii by utilizing mulberry wood chips. The method comprises the steps of raw material collection and process, substrate preparation, bagging, sterilization, cooling, inoculation, spawn runing management and pleurotus eryngii yielding management. According to the technical scheme, the traditional substrate formula of adopting pure cotton seed hulls as the main is changed, an optimized high-yield substrate cultivation formula adopting mulberry sawdust, corns and the like as the main is researched, and the local raw materials are utilized by adjusting measures to local conditions, so that the raw material purchasing difficulty and the production cost are reduced; the good ecological benefits are brought, the leftovers of subsidiary agricultural products such as mulberry sawdust, and corns and the like are fully utilized, so that the industrialization of the modern circular agriculture is realized; and the factorized yearly production is also adopted, and the management mode of environment control intelligence, production operation automation and product quality standardization is realized, so that the produced pleurotus eryngii has good and stable quality.

Owner:蔡光炬

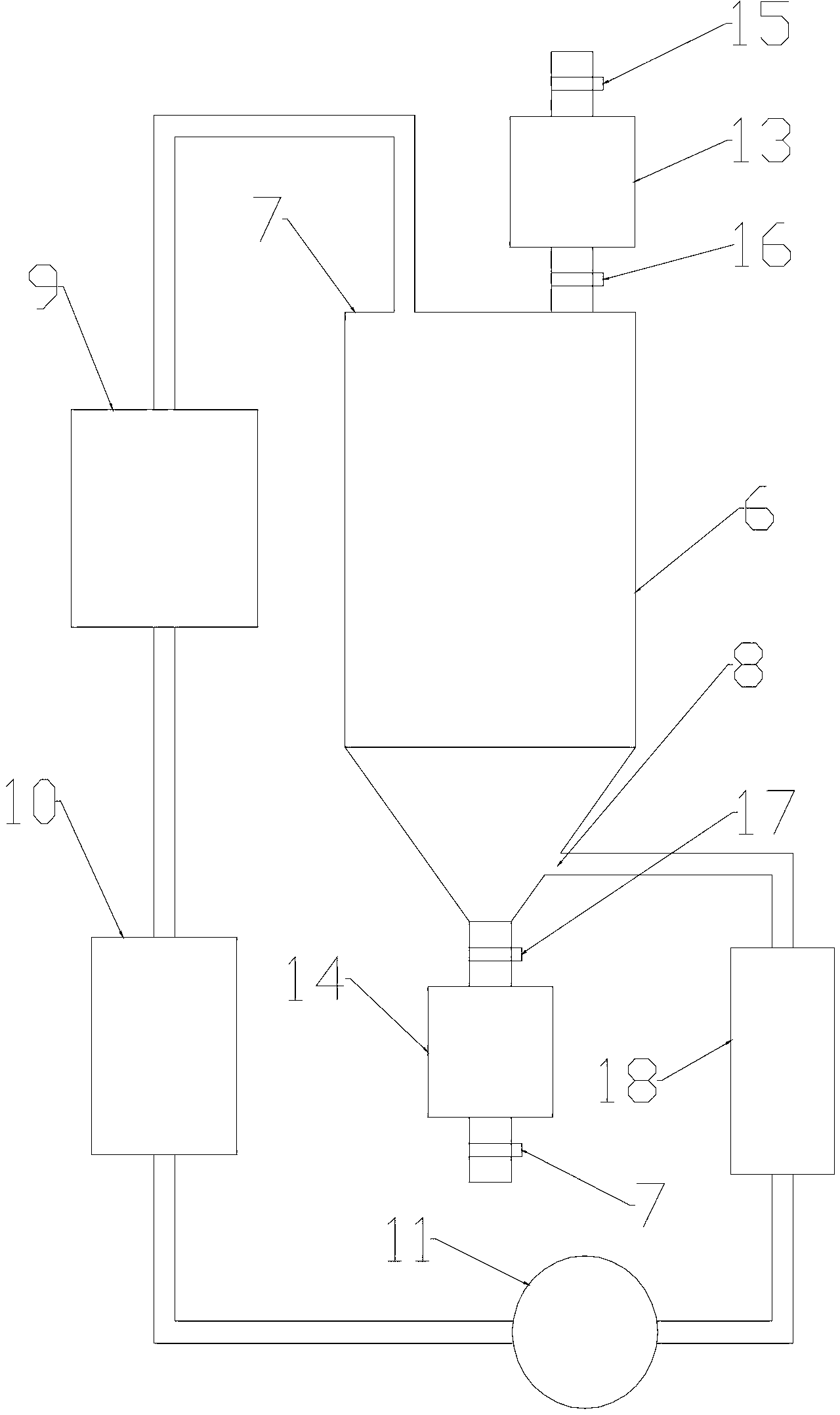

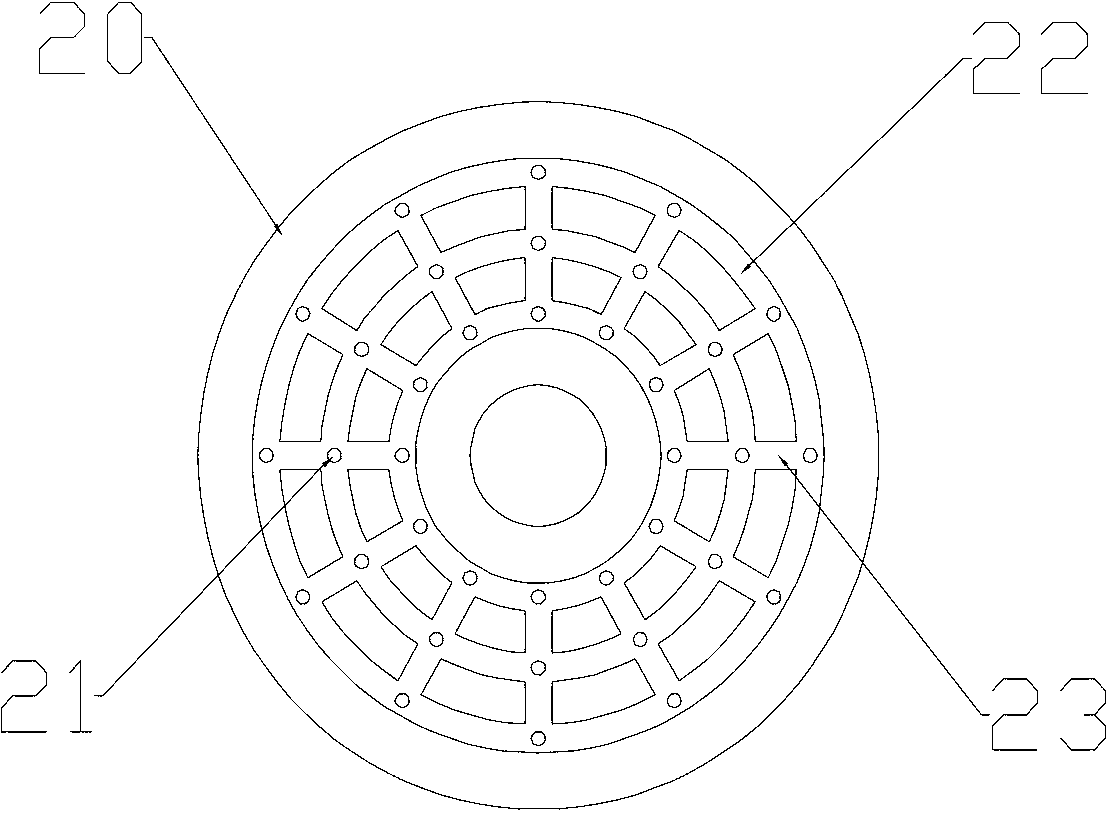

Equipment and process for producing high-performance polyphenylene sulfide fine-denier fiber

ActiveCN103014889AQuality improvementUniform thicknessSpinnerette packsFilament forming substance formingFiberEngineering

The invention discloses equipment and a process for producing high-performance polyphenylene sulfide fine-denier fiber. The equipment comprises a drying system, a screw extruder, a filter, a spinning machine and a cooling device which are connected sequentially, wherein the drying system comprises a drying machine; a gas purification processor, a gas dehumidification processor, a fan and a heater are sequentially connected through gas delivery pipes in a sealed manner between a gas outlet and a gas inlet of the drying machine; the draw ratio of a screw rod of the screw extruder ranges from 26 to 32; the depth of a screw groove at the tail end of the metering section of the screw rod is 3 to 5 mm; an annular spinneret plate is mounted at the lower end of the spinning machine; and a plurality of concentric annular flow guide grooves and radial communicated flow guide grooves are formed in the annular spinneret plate. The process comprises the steps of selecting materials, drying, fusing, jetting silk, cooling and the like. According to the equipment and the process, the structures of a plurality of parts are improved; process steps and parameters are optimized; the produced polyphenylene sulfide fine-denier fiber has high quality stability; the qualified rate of products is high; and according to detection, the polyphenylene sulfide fine-denier fiber reaches or even exceeds the industrial standard and import products in multiple performance parameters.

Owner:SICHUAN UNFIRE POLYMER MATERIALS TECH

Edge switch

InactiveUS7483378B2Avoid network congestionLimiting the amount of packetsEnergy efficient ICTError preventionPacket communicationCommunication quality

An edge switch comprises a token bucket control unit which varies the amount of tokens flowing into a token bucket per unit time in accordance with the congestion condition of an IP network, and the output rate of packets to be output onto a packet communication network is adjusted for each line identifier by controlling the output amount of a packet buffer, in accordance with the amount of tokens held in the token bucket; and, an analyzing unit that determines whether the source address of the received packet matches the address of a preregistered emergency call destination, and the token bucket control unit further reduces, when an emergency call is generated, the amount of tokens flowing into the token bucket for any destination address in congestion, other than the emergency call destination, and thereby retaining communication quality for emergency priority communication.

Owner:FUJITSU LTD

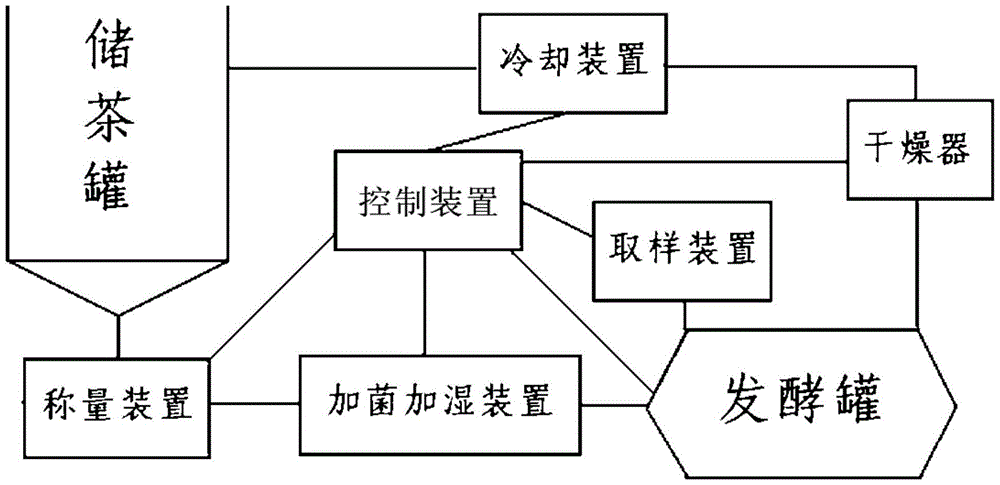

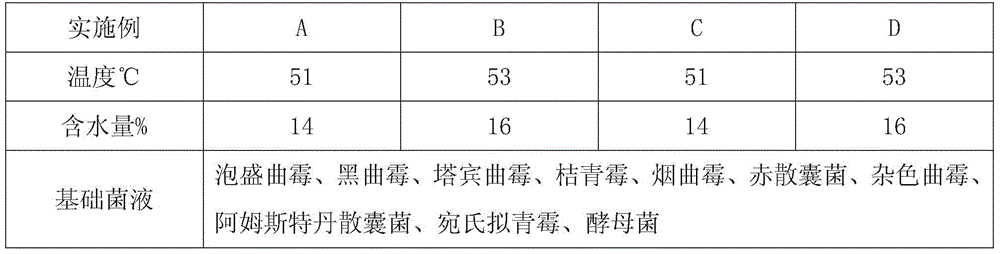

Liupao tea automatic pile fermentation technique and fermentation strain composition

ActiveCN105695339AShorten the fermentation cycleImprove filtration efficiencyFungiPre-extraction tea treatmentAutomatic controlFlavor

The invention discloses a Liupao tea automatic pile fermentation strain composition which comprises a base bacterium solution, a consolidation bacterium solution and an aging bacterium solution. The bacterium solutions contain Aspergillus awamori, Aspergillus niger, Aspergillus tubingensis, penicillium citrinum, Aspergillus fumigatus, Eurotium rubrum, Aspergillus versicolor, Eurotium amstelodami, Paecilomyces variotii, Eurotium niveoglaucum, saccharomycetes and other beneficial microorganisms. On such basis, the inventor establishes the corresponding fermentation technique and equipment; and on the premise of not changing the upstream and downstream main production techniques of the original pile fermentation, the beneficial microorganism florae are added to control the growth of harmful infectious microbes, thereby enhancing the fermentation efficiency, shortening the pile fermentation period, and keeping the special thick flavor of the traditional Liupao tea. The pile fermentation automatic control system is utilized to dynamically monitor and control the changes on temperature, humidity and florae in the whole fermentation process, thereby implementing automation, continuity and high efficiency of the production technique, and ensuring the Liupao tea product to have safe and reliable quality and high and stable quality.

Owner:GUANGXI UNIV

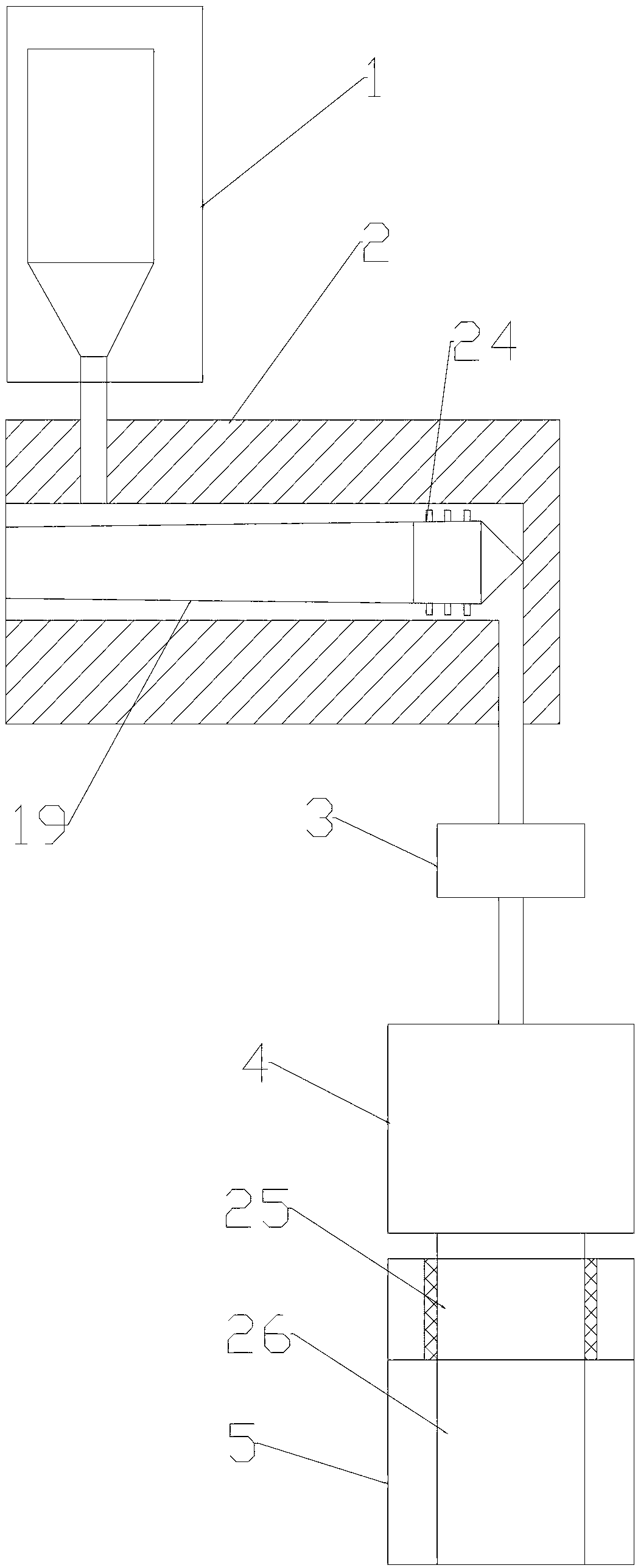

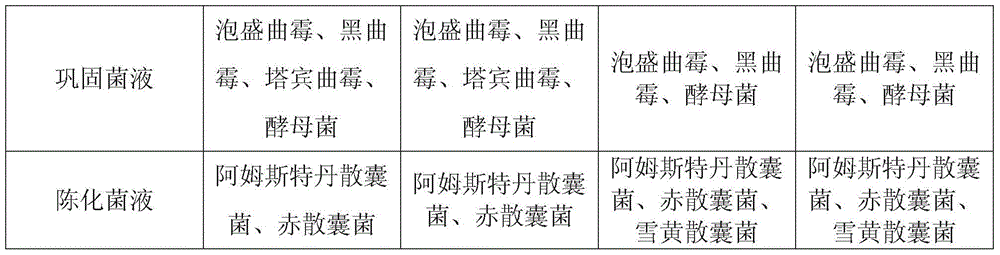

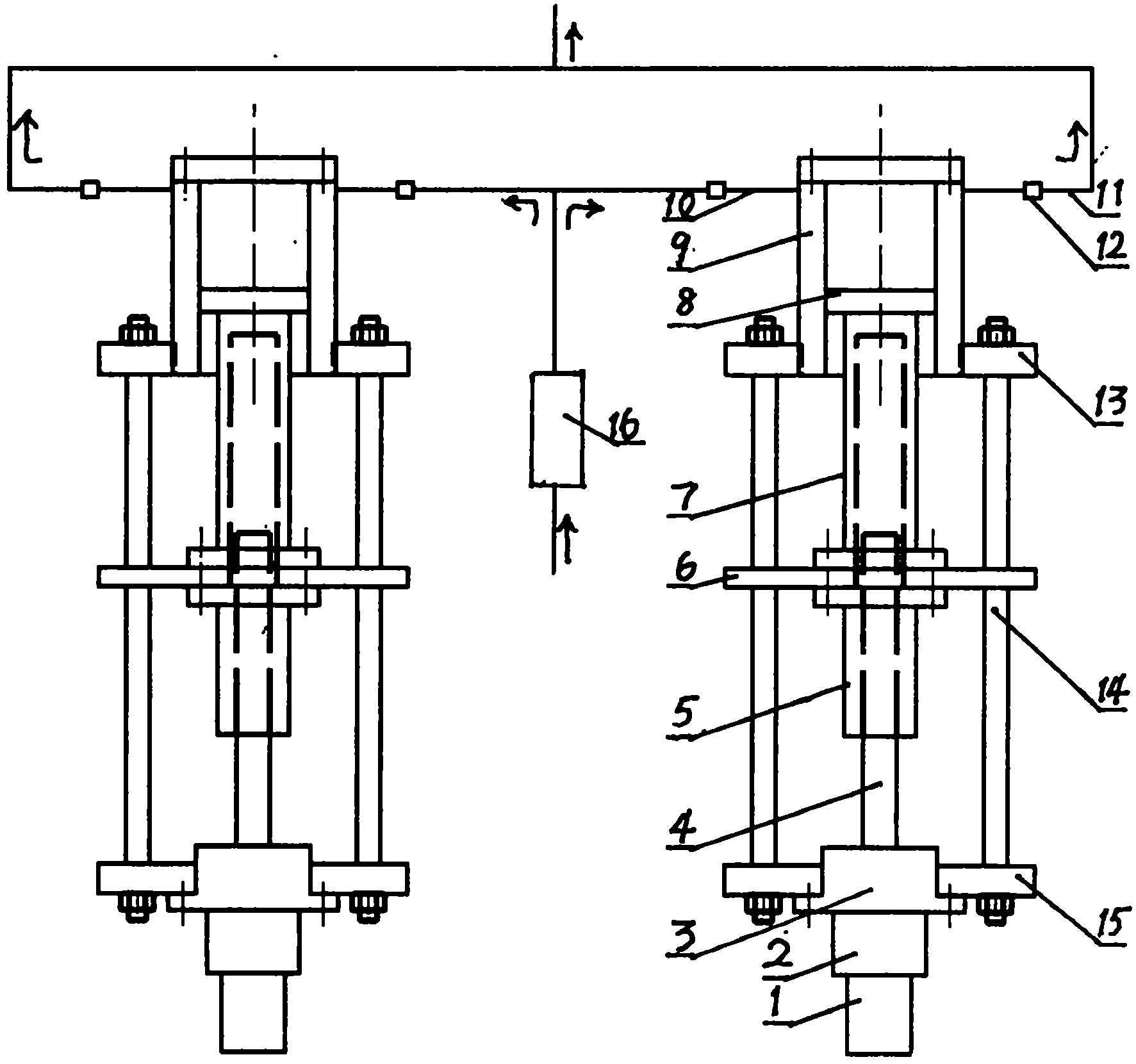

All-electric dual-cylinder linkage injection unit

An all-electric twin-cylinder linkage injection unit, consisting of two sets of injection units with the same structure, each injection unit includes a material cylinder (9), a piston (8), a feed pipe (10) and a discharge pipe (11) , the piston is connected with the ball screw nut (5) through the connecting sleeve (7), the lower end of the ball screw shaft (4) is connected with the precision planetary gearbox (2) through the bearing seat (3), and the latter is connected with the servo motor (1 ) to extend out the shaft connection, fix the upper cross plate (13) of the material cylinder (9) and the lower cross plate (15) of the fixed bearing seat (3), and the slide plate (6) between the two cross plates (13,15) ) are parallel to each other, and the left and right sides of the three have guide posts (14) that also serve as connecting rods. The present invention has the advantages of small size, few pipelines, long service life, energy saving, no noise, high precision, accurate injection volume, material saving, and high-quality products. Stable quality, continuous long-term feeding and super-large or small-capacity feeding, suitable for both injection molding and extrusion molding.

Owner:佘晓峰

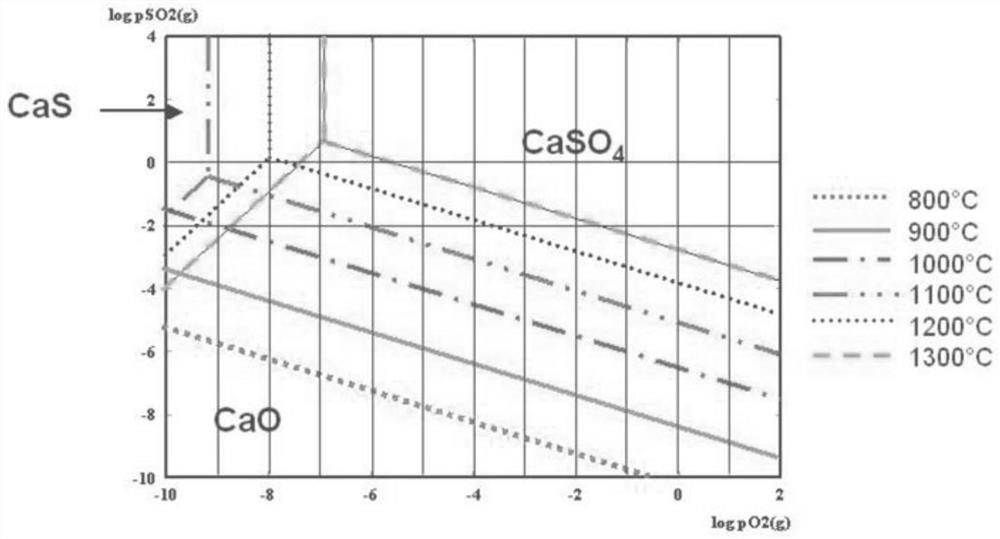

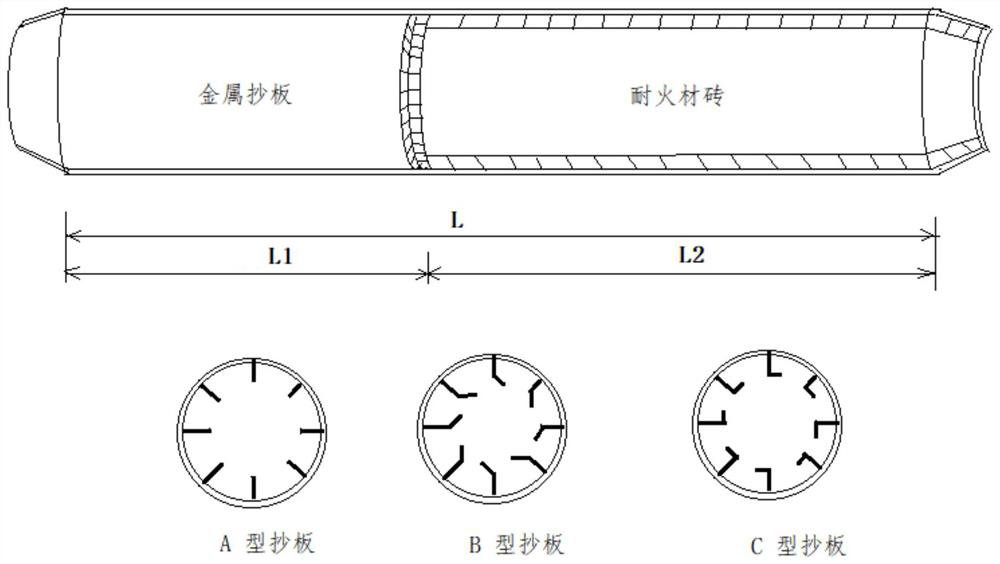

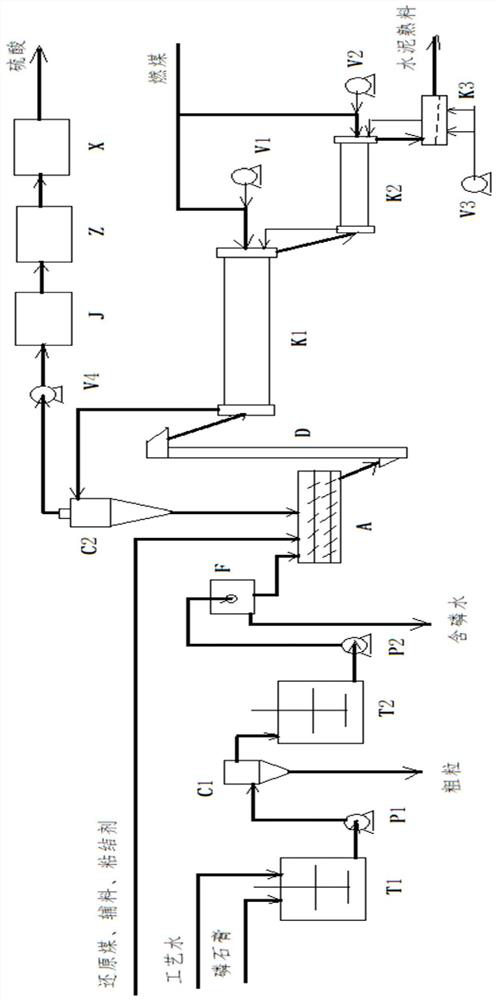

Production method for producing cement and sulfuric acid from phosphogypsum

InactiveCN112694067AImprove product qualityEliminate the environmental problems of stackingSulfur compoundsCeramic production plantsReductive decompositionDust control

The invention discloses a production method for producing cement and sulfuric acid by using phosphogypsum. The method comprises the following steps: carrying out pretreatment purification on phosphogypsum to reduce insoluble phosphorus, water-soluble phosphorus impurities and most free water in the phosphogypsum, kneading with a reducing agent, granulating, and directly feeding the material into a reductive decomposition integrated rotary kiln with fluidization preheating function; controlling a gas phase atmosphere to perform step-by-step heating, drying, dehydration and reductive decomposition under the combustion of the pulverized coal; sulfur dioxide gas generated after reductive decomposition is used for producing sulfuric acid after being subjected to dust removal and purification; and the reduced and decomposed material enters an oxidation calcining kiln for cement clinker sintering, and the gas-phase atmosphere is controlled under the combustion of pulverized coal for heating, mineralizing and sintering to obtain the cement clinker. Compared with the prior art, the production method for producing cement and co-producing sulfuric acid by using phosphogypsum has the advantages that the coal consumption for reduction and firing is reduced, the production efficiency and the product quality are improved, the device investment is saved, the economic benefit of producers is increased, and the environmental protection problem of phosphogypsum stacking treatment is eliminated.

Owner:CHENGDU QIANLIJIN TECHCAL INNOVATION CO LTD

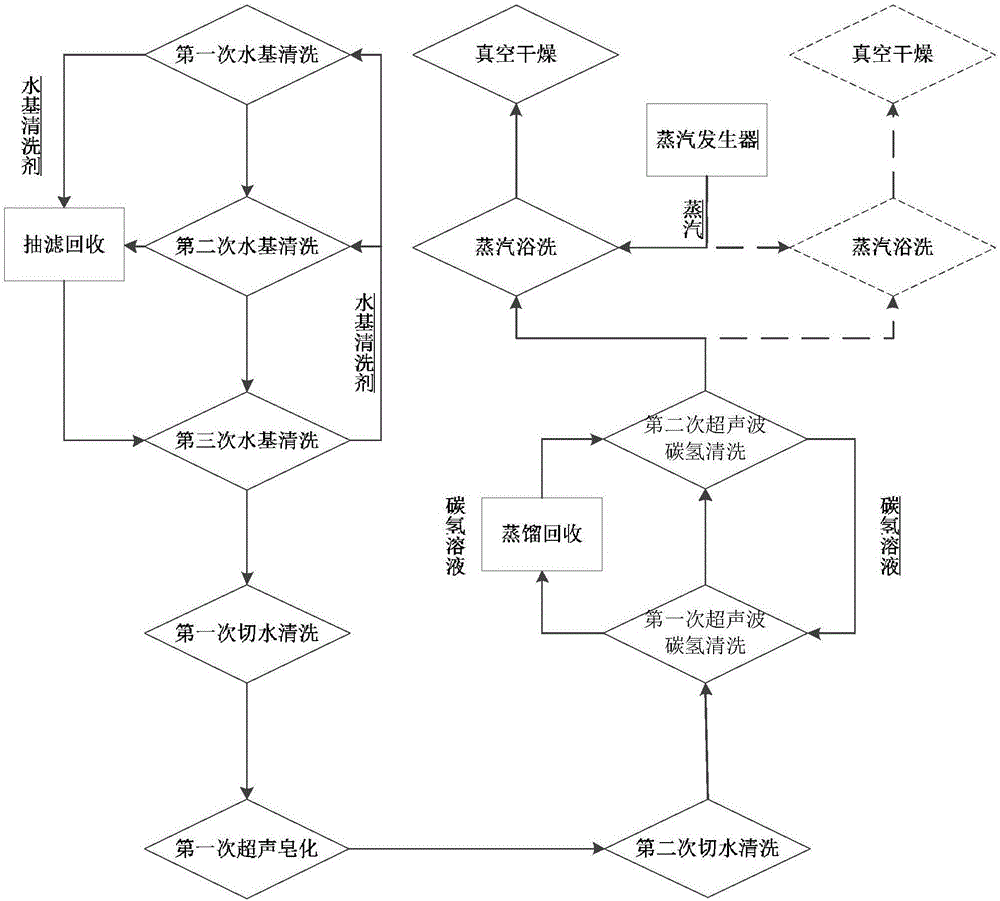

New energy battery case cleaning technology

The invention discloses a new energy battery case cleaning technology. The new energy battery case cleaning technology sequentially comprises the cleaning working procedures of the first time of water base cleaning, the second time of water base cleaning, the third time of water base cleaning, the first time of water draining cleaning, the first time of ultrasonic saponification, the second time of water draining cleaning, the first time of ultrasonic hydrocarbon cleaning, the second time of ultrasonic hydrocarbon cleaning, the first time of vacuum bathing and drying, and the second time of vacuum bathing and drying, wherein a distillation recovery working procedure is arranged between the first time of ultrasonic hydrocarbon cleaning and the second time of ultrasonic hydrocarbon cleaning, a leaching recovery working procedure is arranged between the first time of water base cleaning and the second time of water base cleaning, and a leaching recovery working procedure is arranged between the second time of water base cleaning and the third time of water base cleaning. According to the new energy battery case cleaning technology, precleaning is carried out through the action of emulsification, permeation, cleaning and the like of surfactants, then metathesis is carried out with a hydrocarbon water draining agent, water draining is carried out after ultrasonic saponification is carried out, and at last, strengthened cleaning is carried out with a vacuum hydrocarbon cleaning agent so that dirt on a highlight surface can be thoroughly removed. The new energy battery case cleaning technology is good and stable in quality, and furthermore, the cleaning agent is recyclable, the cost is low, and the influence on the environment is little.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

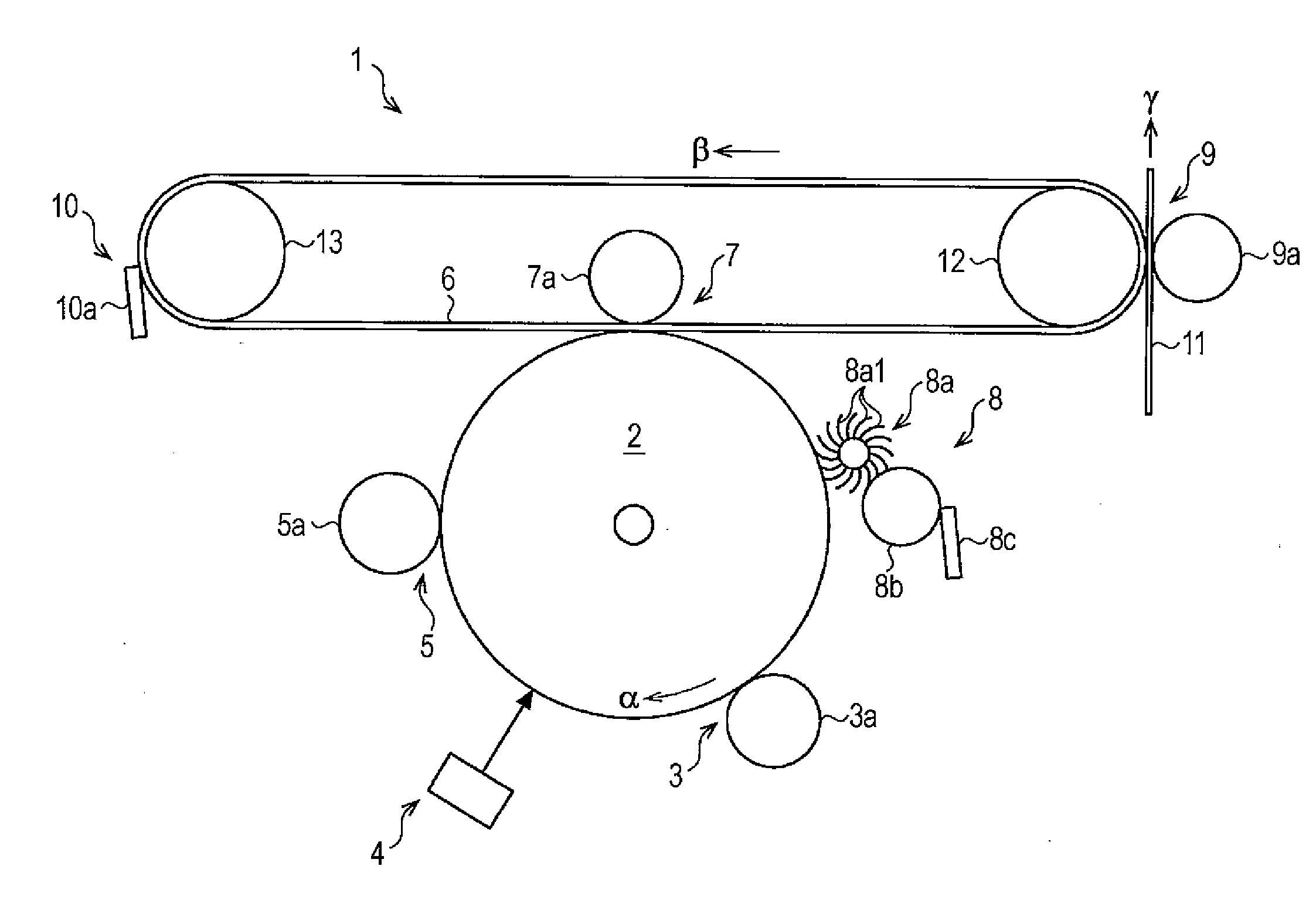

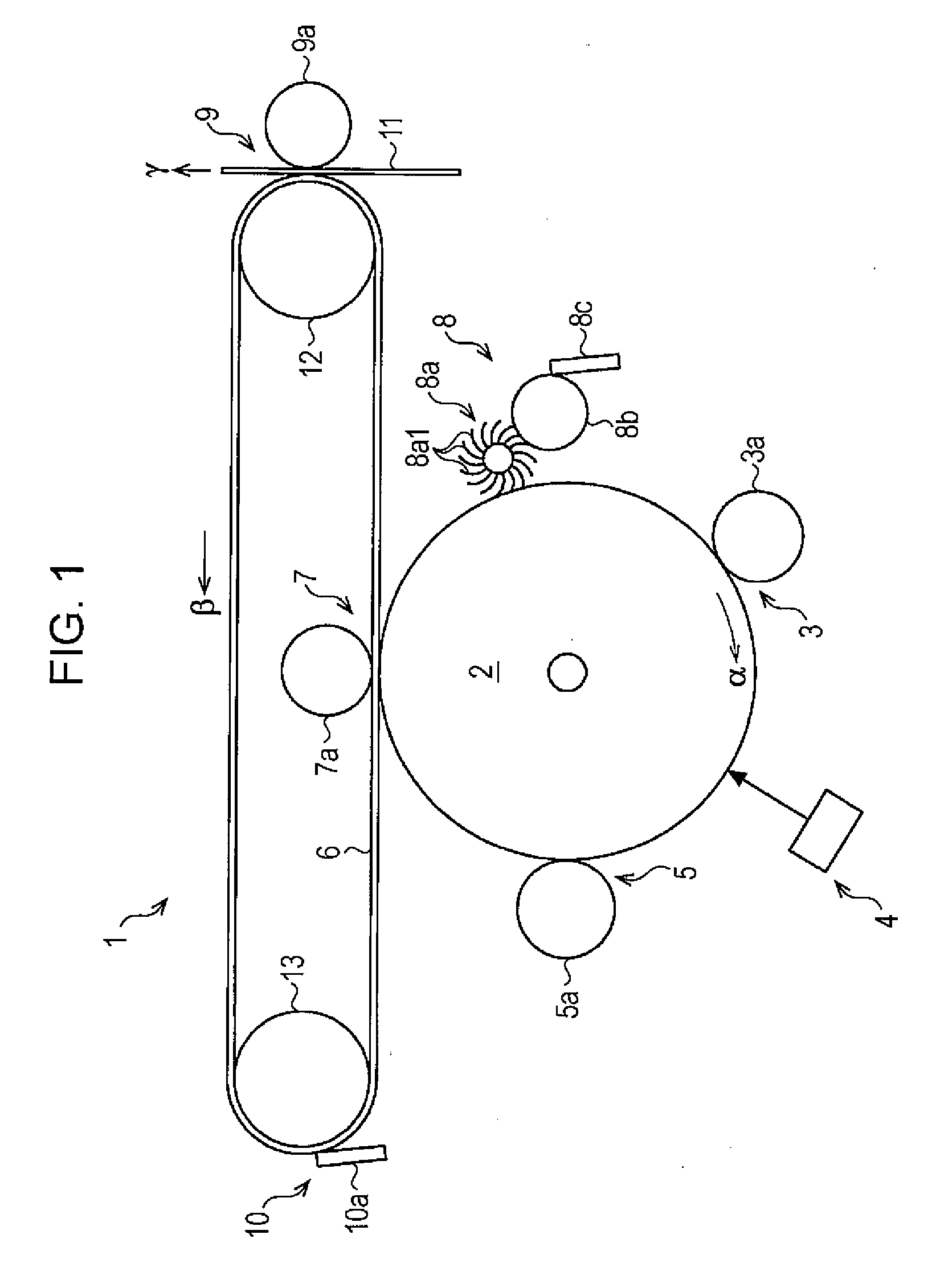

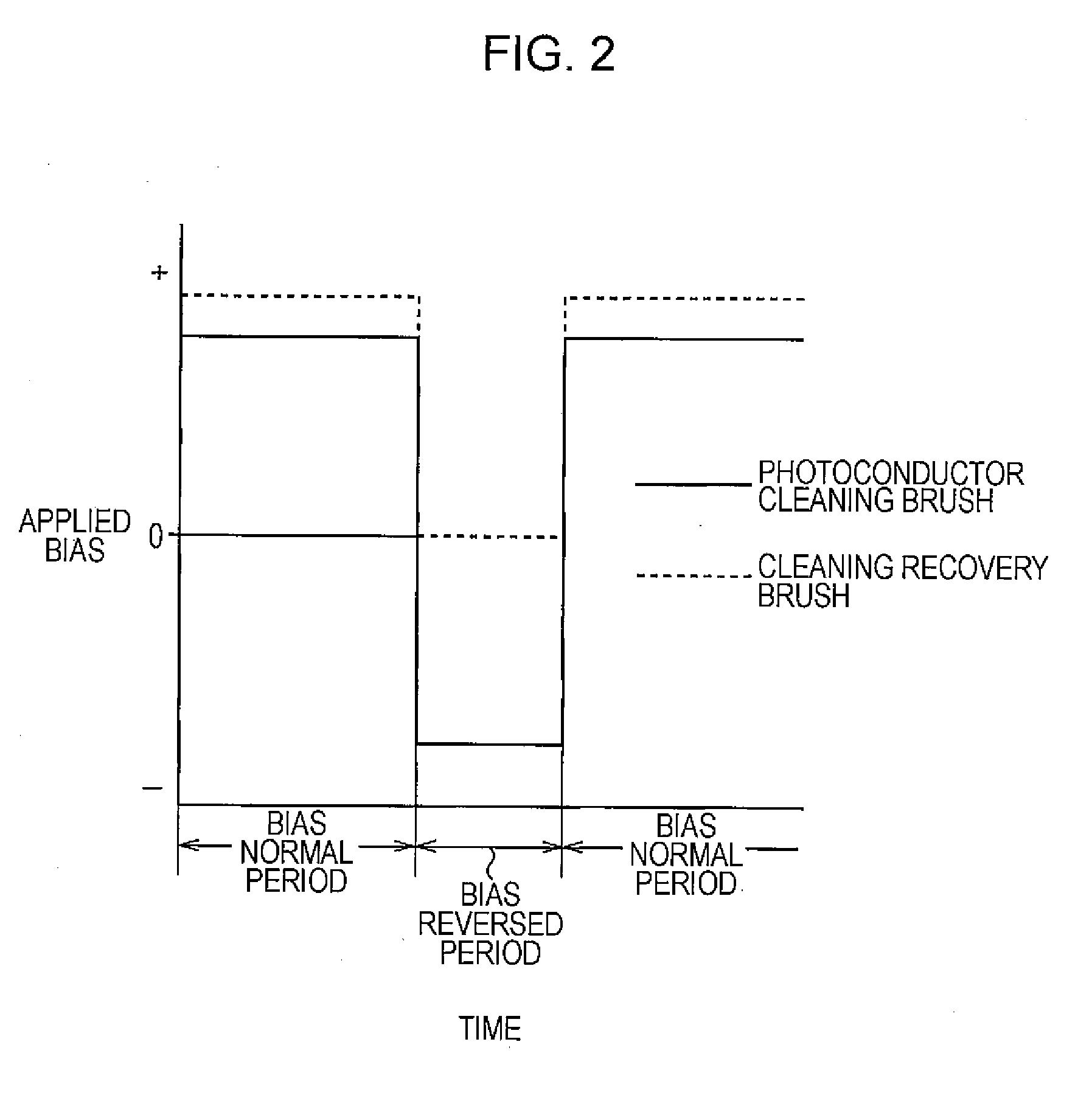

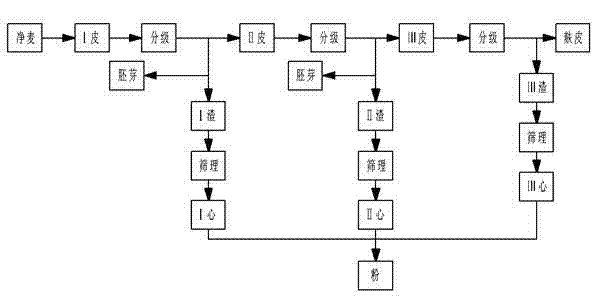

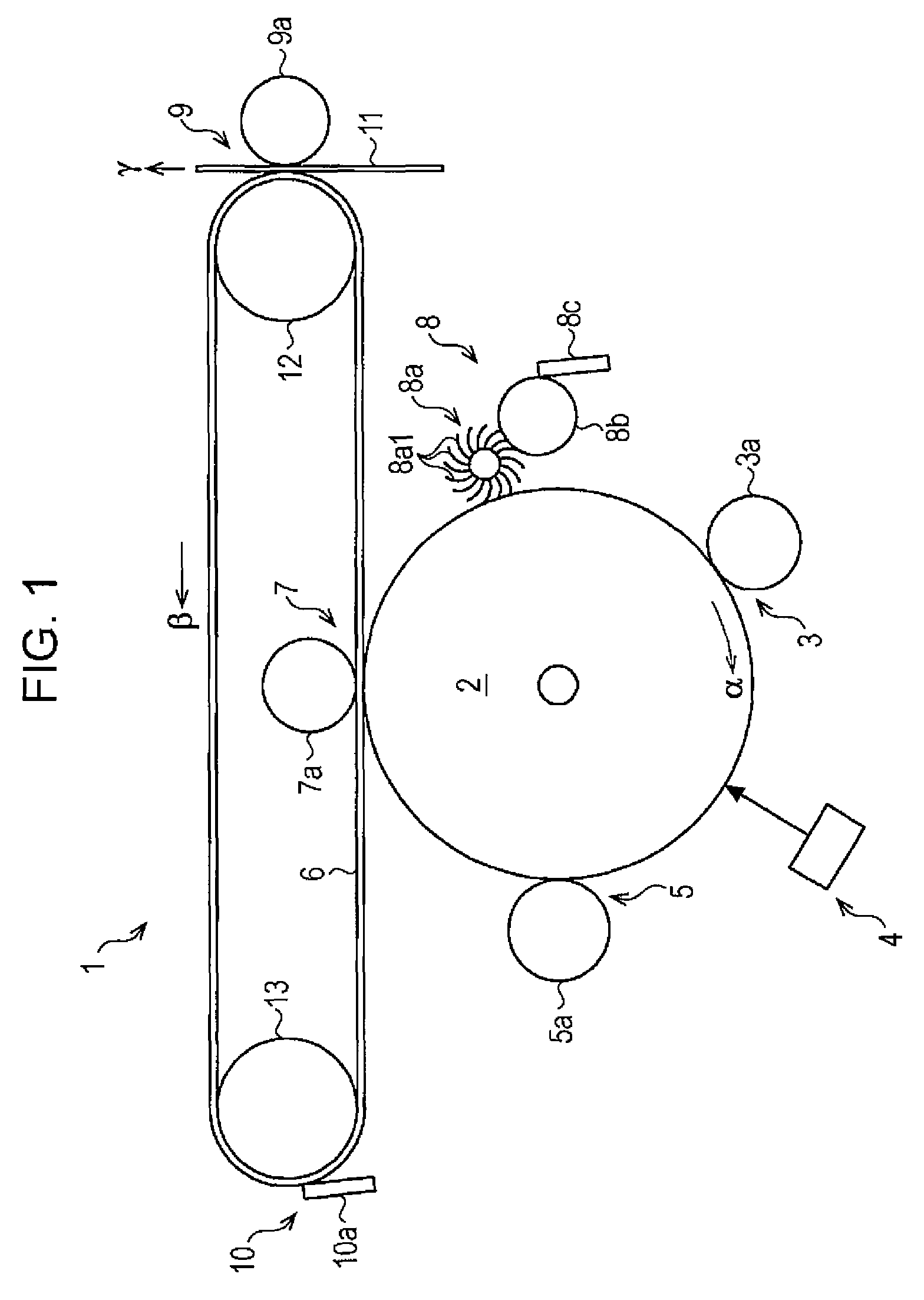

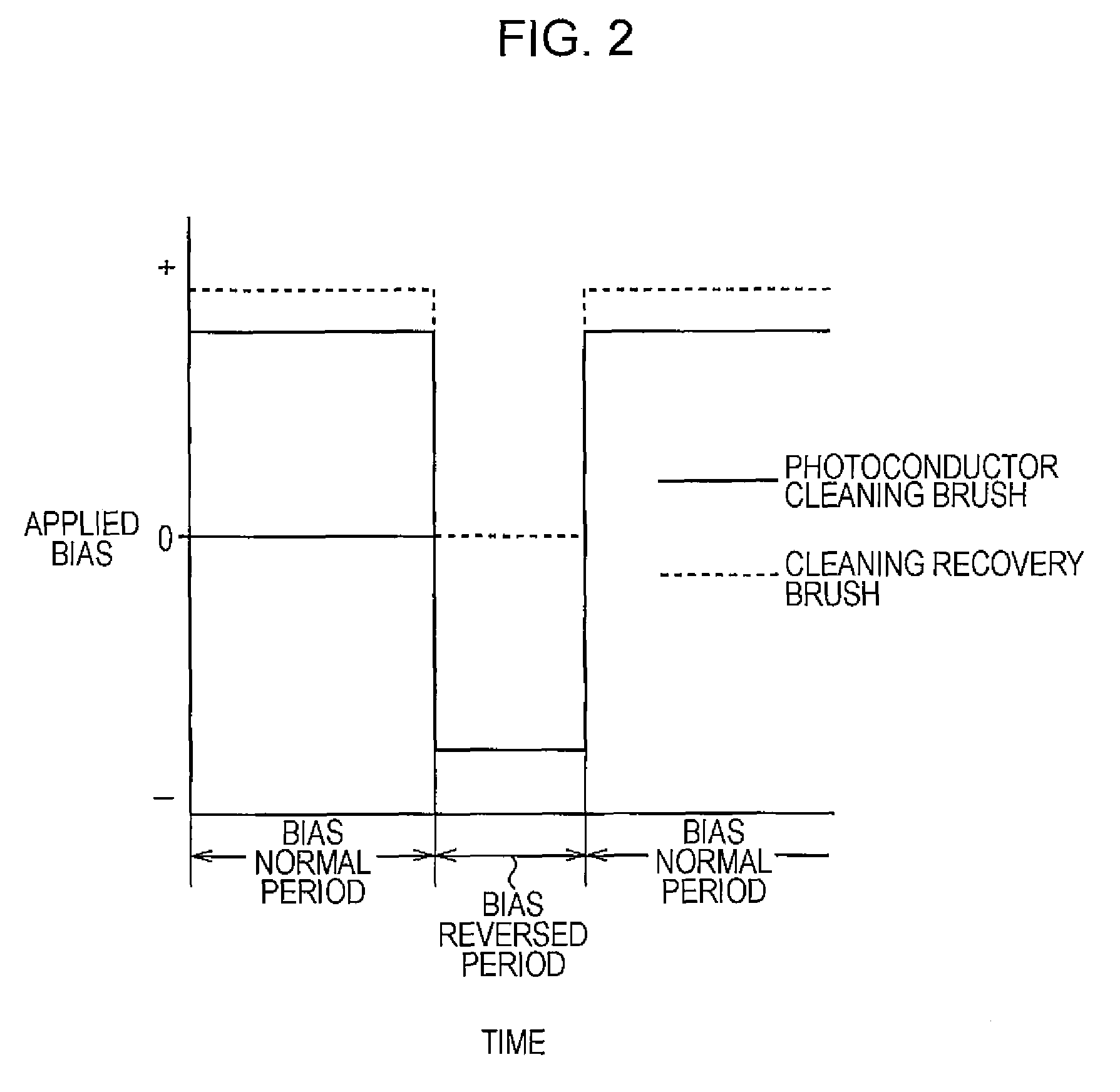

Cleaning Blade Anti-Peeling Apparatus, Image Forming Apparatus, and Cleaning Blade Anti-Peeling Method

InactiveUS20090129810A1Easy and effective cleaningInhibit transferElectrographic process apparatusImage formationVoltage

A cleaning blade anti-peeling apparatus includes an image carrier on which a toner image is formed, a transfer apparatus which transfers the toner image of the image carrier to an endless transfer member, an image carrier cleaning member which captures toner remaining on the image carrier after the toner image is transferred, a cleaning recovery member which recovers the toner on the image carrier cleaning member, a bias applying apparatus which moves the toner of the image carrier cleaning member to the image carrier by applying a bias voltage to the image carrier cleaning member, and an endless transfer member cleaning blade which removes toner adhering to the endless transfer member after the toner image of the endless transfer member is transferred to the transfer material while abutting against the endless transfer member, in which the cleaning blade anti-peeling apparatus is structured to satisfy a relationship, a width of the cleaning recovery member <a width of the endless transfer member cleaning blade <a width of the image carrier cleaning member.

Owner:SEIKO EPSON CORP

Intelligent integrated two-core plug device

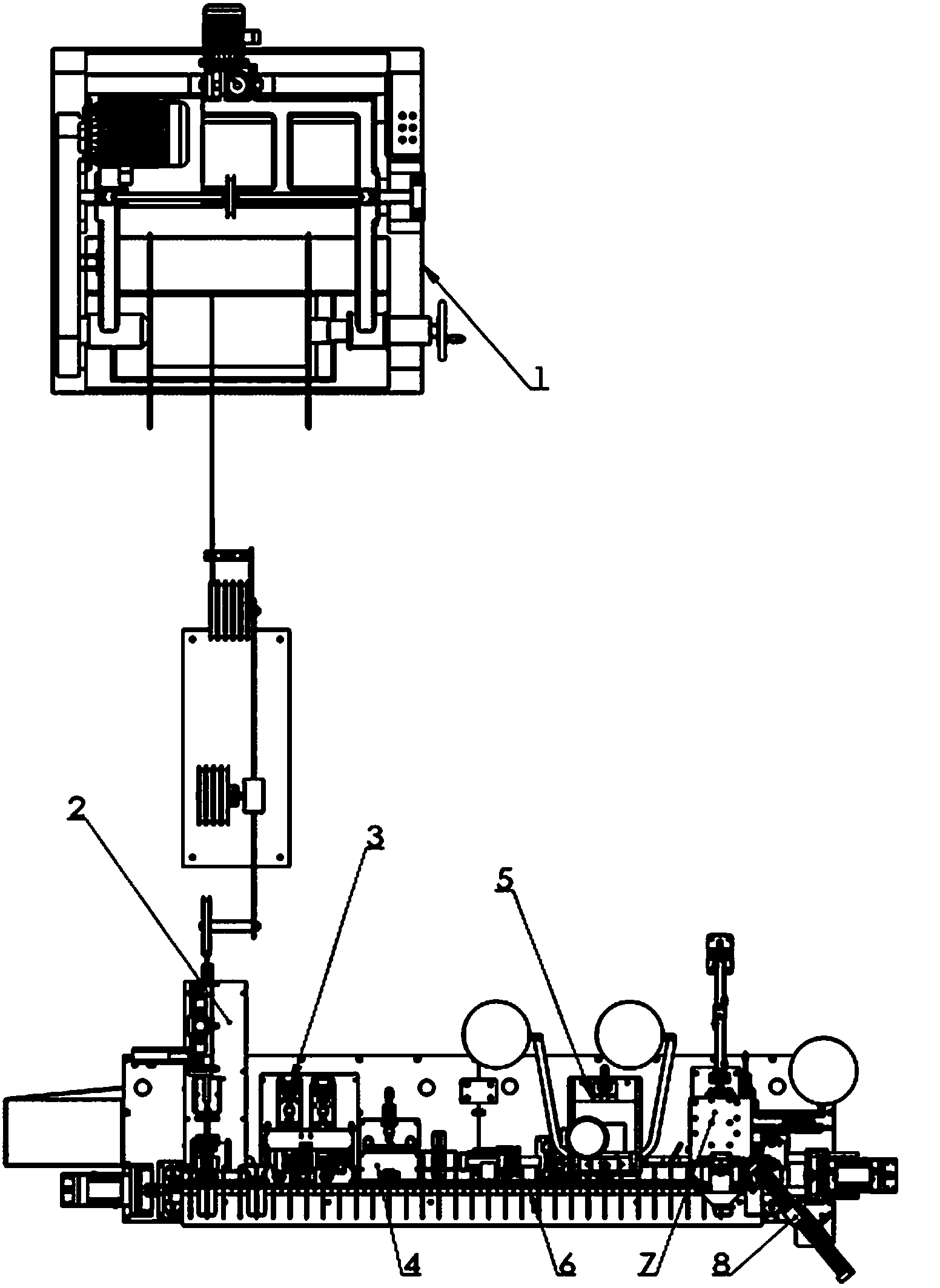

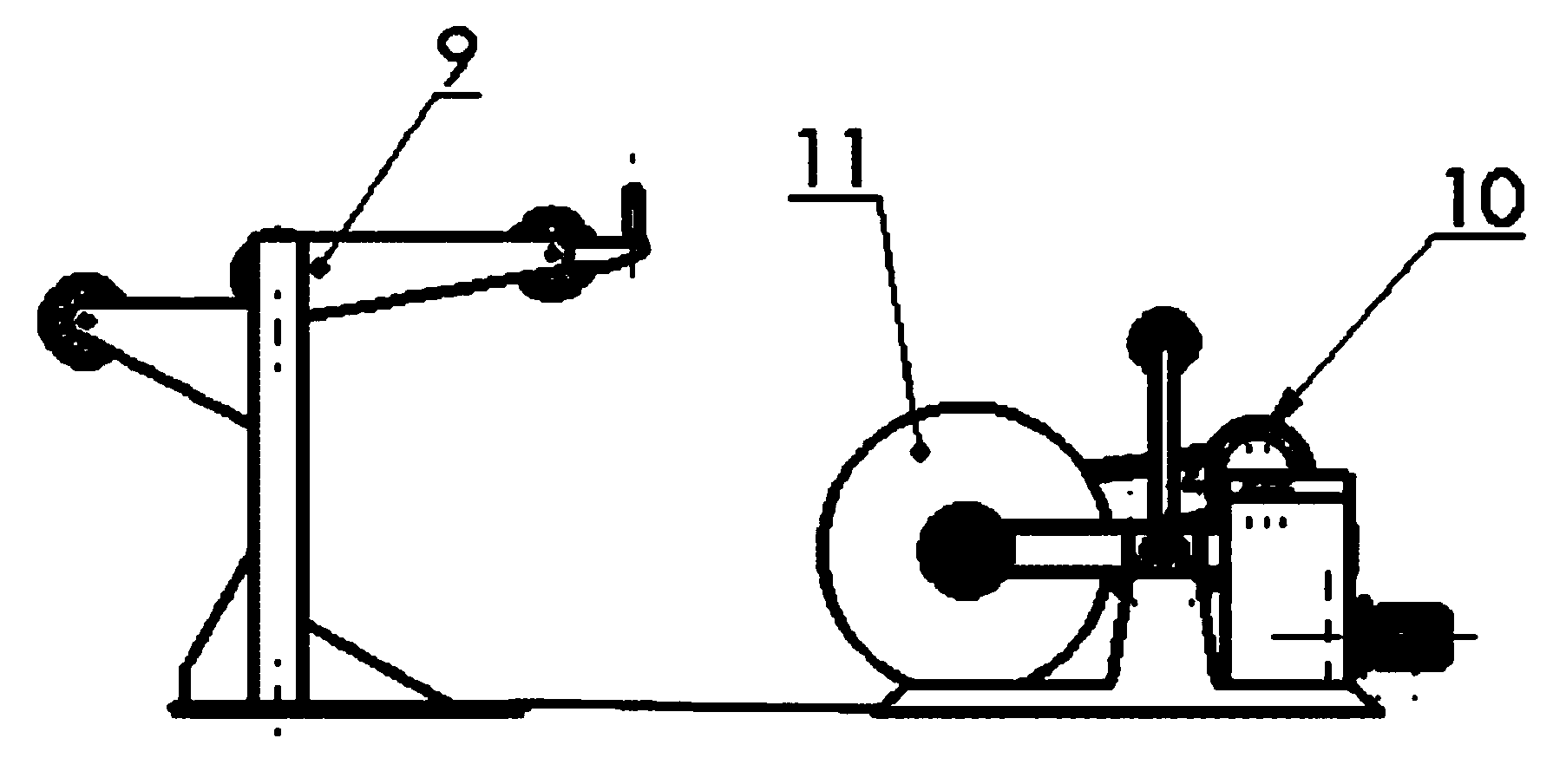

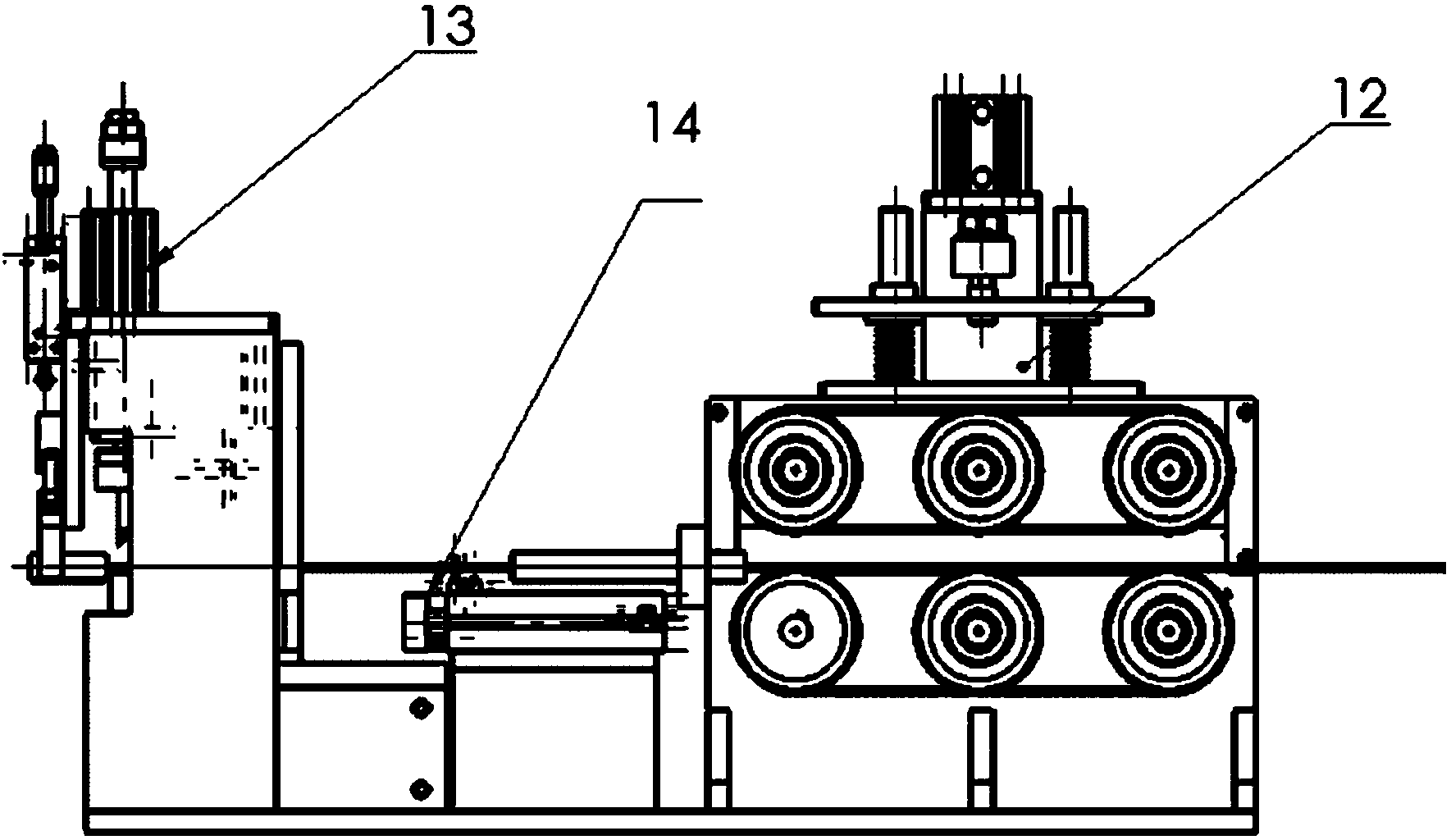

InactiveCN104124596AIncrease productivityImprove qualityContact member assembly/disassemblyConnection formation by deformationEngineeringFixed length

The invention relates to an intelligent integrated two-core plug device comprising power line pay-off machine (1), an automatic power line fixed-length cutting and tail peeling portion (2), a power line head peeling and inner core wire separation portion (3), a power line head inner core wire separation portion (4), a power line head and terminal riveting and fixing portion (5), a power line moving portion between stations (6), a power line head terminal loading skeleton portion (7), and an automatic power line material-taking portion (8). The provided intelligent integrated two-core plug device has the following beneficial effects: full-automatic two-core power plug line production and assembling can be realized; the production efficiency is high; the product quality is excellent and stable; and the production cost is low and the like.

Owner:HEFEI PASE MECHANICAL AUTOMATION

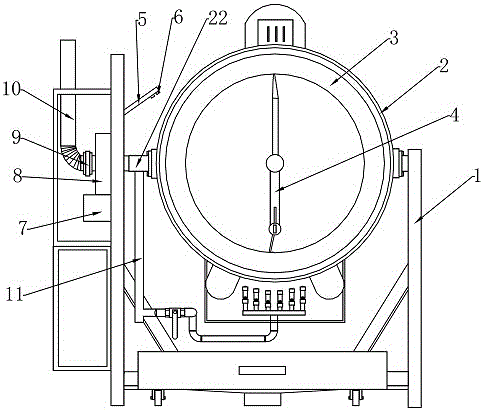

Automatic cooking equipment

ActiveCN106618175AReasonable structureEvenly heatedCooking insertsCooking vessel supportControl systemCantilever

The invention discloses automatic cooking equipment. The automatic cooking equipment comprises a machine frame, a jacket and a pot body which is detachably arranged inside the jacket in an autorotation mode. A heating mechanism is arranged at the bottom end of the jacket, the jacket is connected with the machine frame in a matched mode through a turning shaft and a turning driving mechanism, and a poking fork is arranged inside the pot body and connected with a stirring driving mechanism outside the pot body through a transmission part; a cantilever rod is arranged nearby the opening of the pot body, and a discharging port is formed in the cantilever rod and communicated with a water supply mechanism and / or oil supply mechanism and / or liquid seasoning supply mechanism. The automatic cooking equipment is reasonable in structure; by arranging the rotatable poking fork in the pot body, a dish inside the pot body is fully poked and scattered, all the parts of the dish are heated uniformly; the automatic cooking equipment is used in cooperation with a cooking control system, the dish can be automatically cooked, the quality of the dish is convenient to stabilize, cooking efficiency is high, the automation degree is high, and the requirement for cooking skills is low for an operator.

Owner:WUXI LIBANG KITCHEN UTENSILS +1

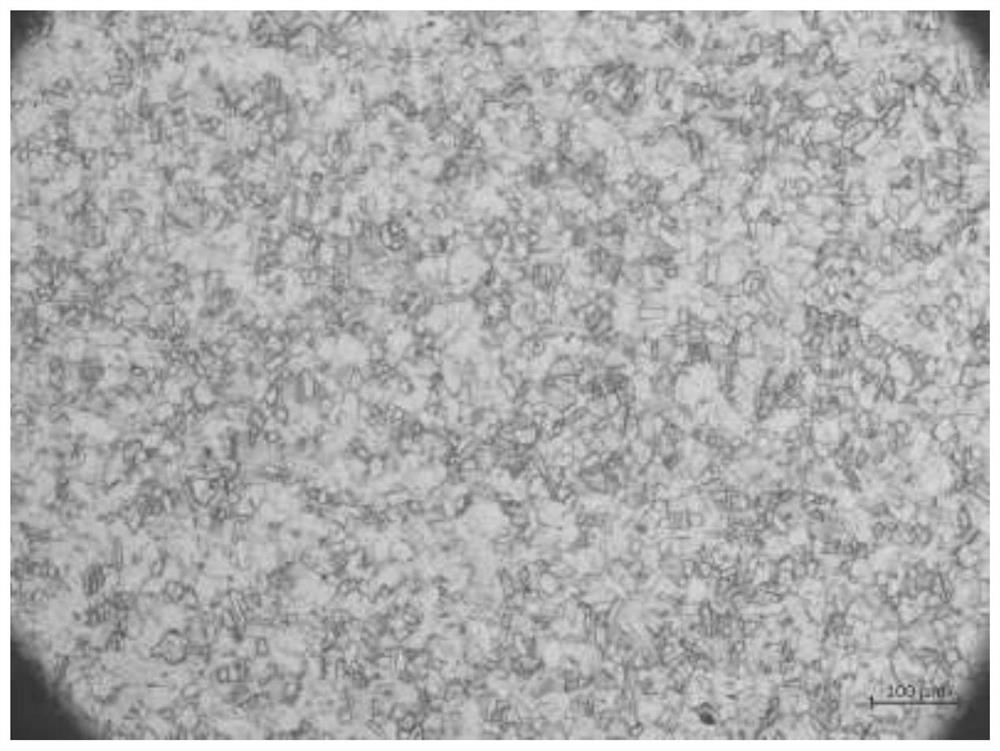

Processing technology of chromium-zirconium-copper contact wire for high-speed electrified railway

ActiveCN111799035AIncrease profitReduce energy consumptionApparatus for heat treatmentConductive materialElectric conductanceMachining process

The invention discloses a processing technology of a chromium-zirconium-copper contact wire for a high-speed electrified railway. The method specifically comprises the following steps: upward continuous casting of a chromium-zirconium-copper rod blank, continuous extrusion, solid solution heat treatment, continuous rolling, aging heat treatment, peeling and drawing to obtain a finished product. According to the process, large-length and large-piece-weight industrial production of the chromium-zirconium-copper contact line of the high-speed railway is realized. The product performance is more excellent. The material structure is further refined and uniform through continuous extrusion and rolling. The average grain size is 10-50 [mu]m, the mechanical performance of the material is further improved, the tensile strength Rm reaches 600 Mpa or above, the conductivity is 80% IACS or above, the advantages of being stable and excellent in quality, high in material utilization rate and the like are achieved, a new way is provided for domestication of the chromium-zirconium-copper contact wire, and the method is suitable for wide popularization.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

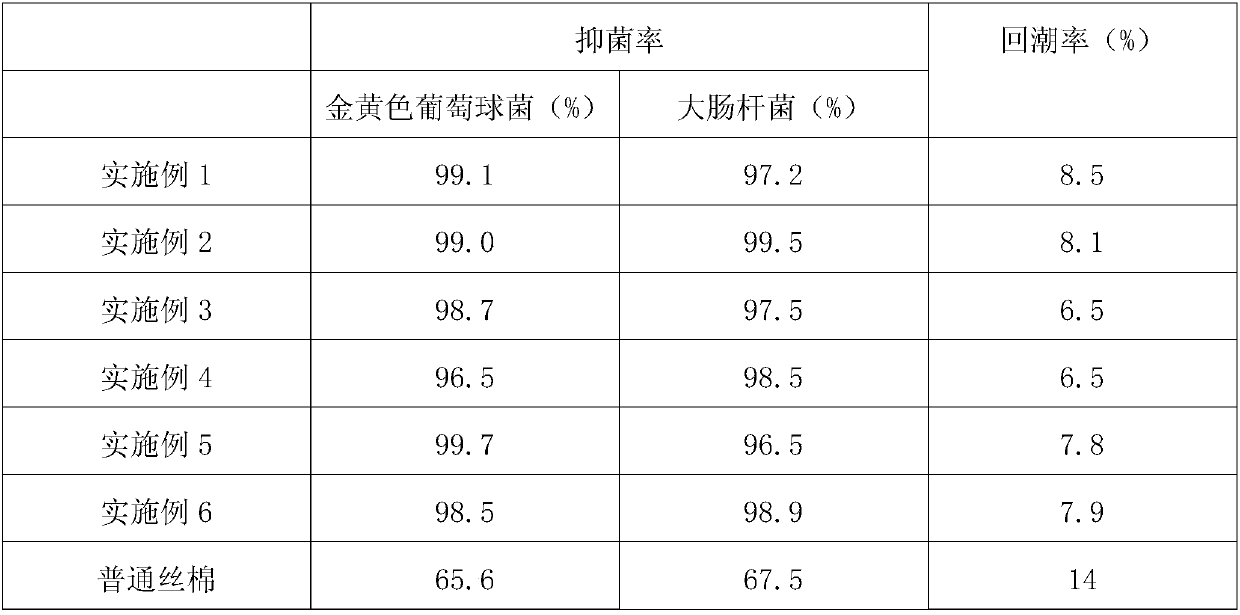

Method for preparing healthcare silk quilt

InactiveCN107669043AIncrease productivityImprove antibacterial propertiesBlanketBiochemical fibre treatmentFiberHusk

The invention belongs to the technical field of silk quilts, and discloses a method for preparing a healthcare silk quilt. The method comprises the following steps that 1, silkworm cocoon raw materials are manually screened; 2, the silkworm cocoon raw materials are dried; 3, after husks on the outermost layers of dried silkworm cocoons are removed, the cocoons are peeled and made into silk pieces;4, the silk pieces are soaked, stirred, cleaned and dehydrated; 5, the dehydrated silk pieces and a degumming agent are placed in a cocoon cooking machine to be stewed, then the silk pieces are fastcleaned with cold water for cooling, then the silk pieces are placed in a drying machine to be dehydrated, and the silk pieces are dried till the water content ranges from 10% to 15%; 6, a finishing agent and natural aromatic are sprayed to the surfaces of the silk pieces; 7, the silk pieces are stretched and spread into multiple layers, and a layer of cotton fibers soaked with the natural aromatic is spread between every two layers; 8, a cotton kneading machine is used for planishing, and the healthcare silk quilt is obtained. The production efficiency is high, and the prepared healthcare silk quilt is good in filling power and tension, and has the healthcare functions of resisting bacteria, preventing mites, preventing insects and the like.

Owner:YIZHOU ZHUANGGE SILK

Side jet flow control based elastic vibration suppressing method

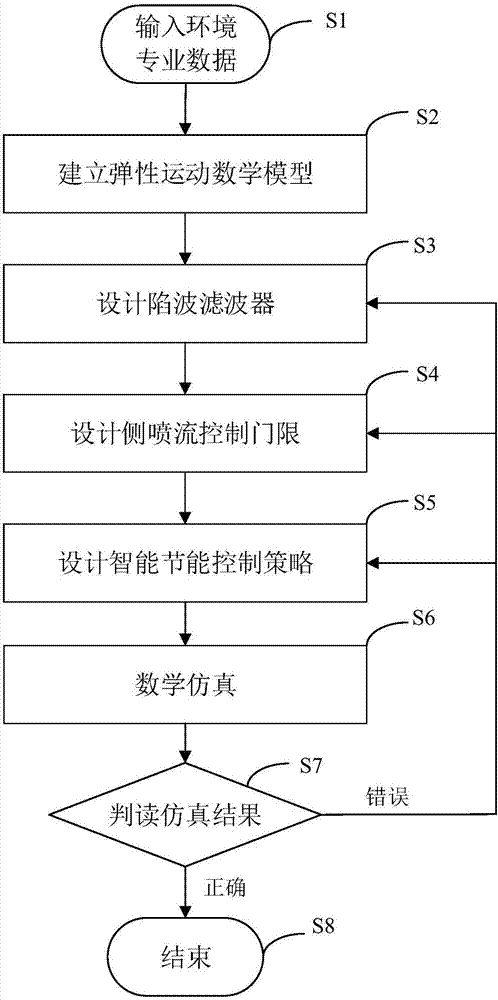

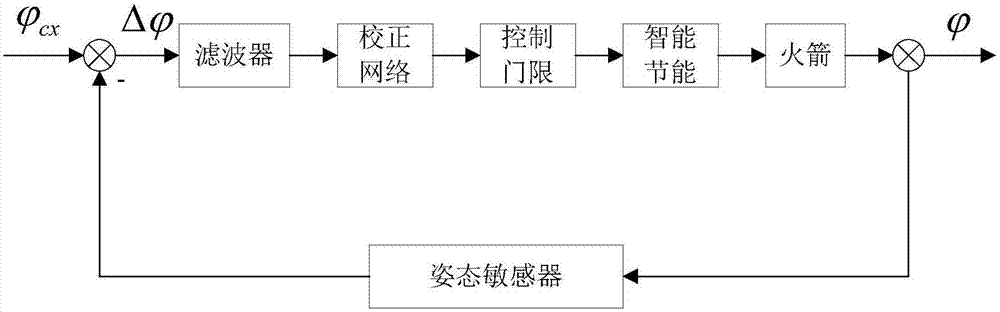

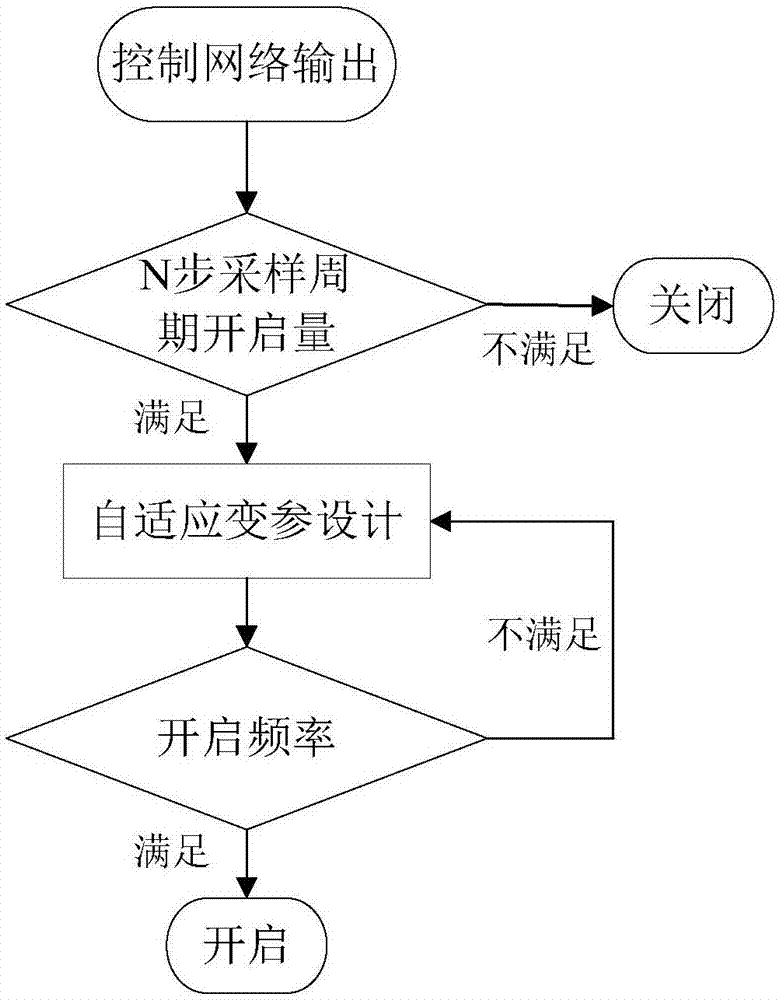

ActiveCN107515612AReasonably control the opening frequencyLow costCosmonautic vehiclesCosmonautic partsJet flowAttitude control

The invention relates to a side jet flow control based elastic vibration suppressing method. The method includes steps of S1, inputting data of environment specialty; S2, according to elastic movement related data provided by the environment specialty, establishing a mathematics model of elastic arrow angular velocity generated by a side jet flow switch action; S3, designing a corresponding filter according to the elastic movement property of the arrow; S4, designing a control threshold matching the control property and controlling the opening frequency of a side jet flow spray pipe reasonably; S5, designing an intelligent energy-saving control strategy so as to enable the self-adaptive adjustment on the threshold of the opening frequency. According to the invention, intelligent self-adaptive control strategy of the switching action of a side jet flow attitude control engine can be realized, interference on attitude control due to high frequency elastic vibration can be suppressed in the maximal level, so that the control efficiency is enhanced substantially and demands for attitude control precision of a solid carrier rocket are met.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

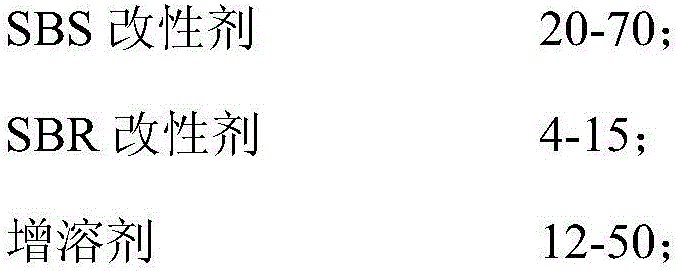

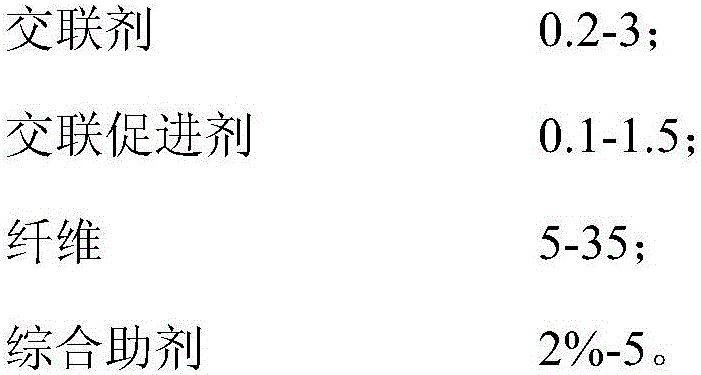

Composite modifier and high-scattering-resistance drainage asphalt concrete prepared through same

ActiveCN106630731AImprove adhesionImprove heat aging resistanceClimate change adaptationCeramicwareFiberCross-link

The invention discloses a composite modifier and a high-scattering-resistance drainage asphalt concrete prepared through the same and relates to the field of road engineering materials. The composite modifier is composed of base materials, fiber, comprehensive additives, cross-linking agent and cross-linking promoter, wherein the base materials are composed of SBS (styrene-butadiene-styrene) modifier, SBR (styrene butadiene rubber) modifier and solubilizer. The drainage asphalt concrete prepared through the composite modifier is high in scattering resistance. Through field deployment of conventional asphalt, aggregate, mineral powder and the composite modifier, a high-performance and stable-performance drainage mixture can obtained and meanwhile is more stable in properties compared with those applying modified asphalt, so that worries on storage segregation and performance degradation of the modified asphalt can be saved, and meanwhile construction deficiencies of dispersing non-uniformity of fiber deployment and grease spots can be completely avoided.

Owner:BEIJING ZHONGLU PAVING TECH +2

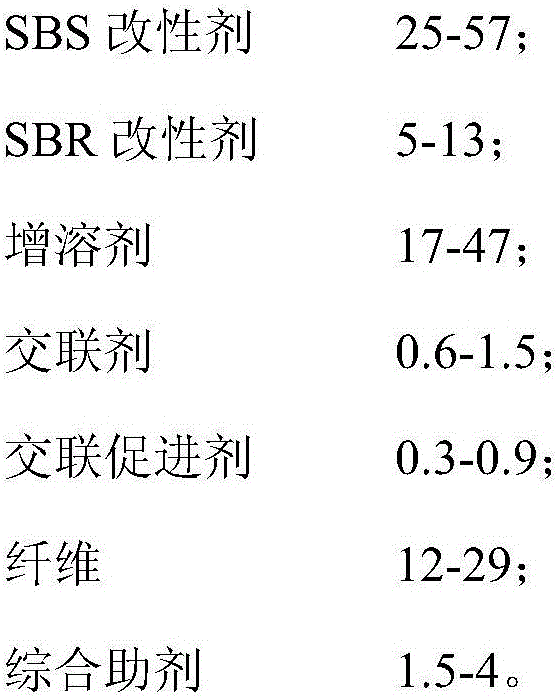

Wheat milling process

The invention belongs to the technical field of flour production and particularly relates to a wheat milling process. The wheat milling process can separate wheat germs independently and is simple in unit combination, high in flour yield and good in quality. The wheat milling process adopts the technical scheme that cleaned and wetted clean wheat with the moisture content of 14.4-14.8% is continuously fed to a I shelling mill, a II shelling mill and a III shelling mill, then to a I slag mill, a II slag mill and a III slag mill after classification, and finally to a I core mill, a II core mill and a III core mill, outlet flour is collected, and the flour entering a high box screen is obtained. The wheat milling process is widely applied to the field of wheat milling.

Owner:山西天美食品有限公司

Method for processing high-grade and high-quality chrysanthemum beverage

The invention provides a method for processing a high-grade and high-quality chrysanthemum beverage. The method comprises the following steps of: killing green of high-quality feverfew or buds (chrysanthemum buds), which serve as raw materials, by a wire mesh belt steam heat green killing machine with steam and hot air, and then heating, dewatering and drying the processed high-quality feverfew or buds in a closed container with vacuumizing, refrigerating and heating functions under a certain vacuum degree and a certain refrigeration condition until the moisture content of the dried feverfew or buds is less than or equal to 10 percent. The chrysanthemum beverage product keeps more effective substances such as flavones and has the advantages that the color and the form are natural, fresh and live, the fragrance is mellow and rich, the flavor is purely sweet and the quality is high.

Owner:GUANGXI GUILIN TEA RES INST

Frozen fermented glutinous rice or rice noodle products and key preparation method thereof

The invention relates to frozen fermented glutinous rice or rice noodle products and a key preparation method thereof. The products comprise a frozen pure fermented glutinous rice product and a mixedfrozen rice noodle product of fermented glutinous rice and other rice noodles. The key preparation method adopts drying and freezing techniques. Limited by the problems that the fermented glutinous rice is not easy to form due to high water content and not easy to dewater due to high sugar degree, starch is easy to age in products, and the like, the varieties of products using the fermented glutinous rice as a raw material are few, all the products cannot serve as convenient staple food, and the market rate is extremely low. The frozen fermented glutinous rice or rice noodle products are characterized in that glutinous rice and the like are used as raw materials to be fermented into fermented glutinous rice, and then the fermented glutinous rice is subjected to boiling, grinding, drying (partial dewatering) or addition of rice noodles, cooling, forming and freezing to obtain cooked or half-cooked frozen products. When eaten, the frozen fermented glutinous rice or rice noodle products are heated by roasting, frying, deep-frying, steaming, microwaving and the like. The products provided by the invention are purely natural fermented food, are sour, sweet, mellow, fragrant and chewy inmouthfeel, can serve as staple food or non-staple food, can be subjected to large-scale and standardized production, have a long shelf life, a simple and convenient preparation method, simple equipment and low cost, and can be prepared at home.

Owner:HARBIN UNIV OF COMMERCE

Cleaning blade anti-peeling apparatus, image forming apparatus, and cleaning blade anti-peeling method

InactiveUS7929880B2Easy and effective cleaningInhibit transferElectrographic process apparatusImage formationEngineering

A cleaning blade anti-peeling apparatus includes a transfer apparatus that transfers a toner image formed on an image carrier to an endless transfer member. An image carrier cleaning member captures toner remaining on the image carrier after the toner image is transferred. A cleaning recovery member recovers the toner on the image carrier cleaning member. A bias applying apparatus applies a bias voltage to move the toner of the image carrier cleaning member to the image carrier. An endless transfer member cleaning blade removes toner adhering to the endless transfer member after the toner image of the endless transfer member is transferred to a transfer material while abutting against the endless transfer member. The following relationship is satisfied: cleaning recovery member width<endless transfer member cleaning blade width<image carrier cleaning member width.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com