Automatic cooking equipment

An automatic cooking and equipment technology, applied in cooking utensils, cooker brackets, plug-ins, etc., can solve the problems of leafy vegetables easily adhering to the inner surface of the pot, the influence of the oil temperature rising speed, and the cumbersome cleaning of the pot body. Facilitates stable quality, high cooking efficiency, and low cooking skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

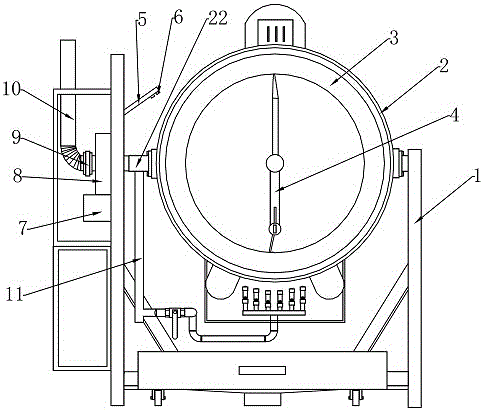

[0032] Such as Figure 1-2 As shown, the automatic cooking equipment in Embodiment 1 includes a frame 1, a jacket 2 and a pot body 3. The pot body 3 is detachably and rotatably arranged in the jacket 2, and the bottom end of the jacket 2 is provided with a heating mechanism 4. The jacket The overturning shaft 22 and the overturning drive mechanism are connected with the frame 1. A shift fork 4 is arranged inside the pot body 3, and the shift fork 4 is connected with the stirring drive mechanism outside the pot body through a transmission member; a cantilever rod is arranged near the opening of the pot body 3. 5. The cantilever rod 5 is provided with a material outlet 6, and the material outlet 6 communicates with the water supply mechanism and / or the oil supply mechanism and / or the liquid seasoning mechanism.

[0033]In Embodiment 1, the heating device is a gas burner, and the turning drive mechanism includes a turning motor 7 and a reducer 8, and the reducer 8 is connected to...

Embodiment 2

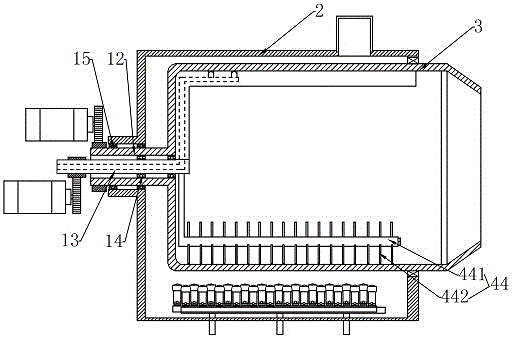

[0038] Such as Figure 3-5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the suspended end of the cantilever rod 5 is provided with two discharge ports 6, and the discharge ports 6 are respectively connected with the discharge pipe 16 in the cantilever rod 5, and a discharge pipe 16 communicates with the oil supply mechanism, and another discharge pipe 16 communicates with the water supply mechanism and / or the liquid seasoning mechanism.

[0039] Oil, water, soy sauce, vinegar and cooking wine are all in liquid state, and its feeding mechanism includes a feeding pipe connected with the oil phase, soy sauce, vinegar and cooking wine storage tanks, and a booster pump is connected on the feeding pipe.

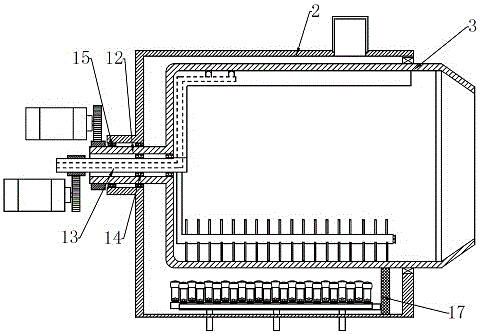

[0040] The outer edge of the silica gel layer 42 is attached to the inner surface of the pot body 3, and there is a gap between the probe of the temperature sensor 43 and the inner surface of the pot body. A fire baffle 17 is provided on the inner surface...

Embodiment 3

[0042] Such as Figure 6-8 As shown, the difference between embodiment 3 and embodiment 2 is that the outer edge of the silica gel layer is blade-shaped, and the outer edge of the blade-shaped silica gel layer contains a magnetic metal sheet 18, and between the edge-shaped silica gel layer outer edge and the pot body 3 is In line contact, the outer surface of the jacket 2 is provided with an electromagnetic element 19 for controllably absorbing the magnetic metal sheet 18 .

[0043] The bottom of the pot body is provided with a vegetable washing tank 20. The vegetable washing tank 20 includes a drawer 201 for holding a vegetable dish and a sink body 202 positioned at the lower end of the drawer. The bottom surface of one end of the drawer 201 is provided with first casters 21. A caster 21 is in contact with the base surface carrying the cooking equipment. The bottom surface of the drawer 201 and the top surface of the sink body 202 are connected by sliding fit or rolling fit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com