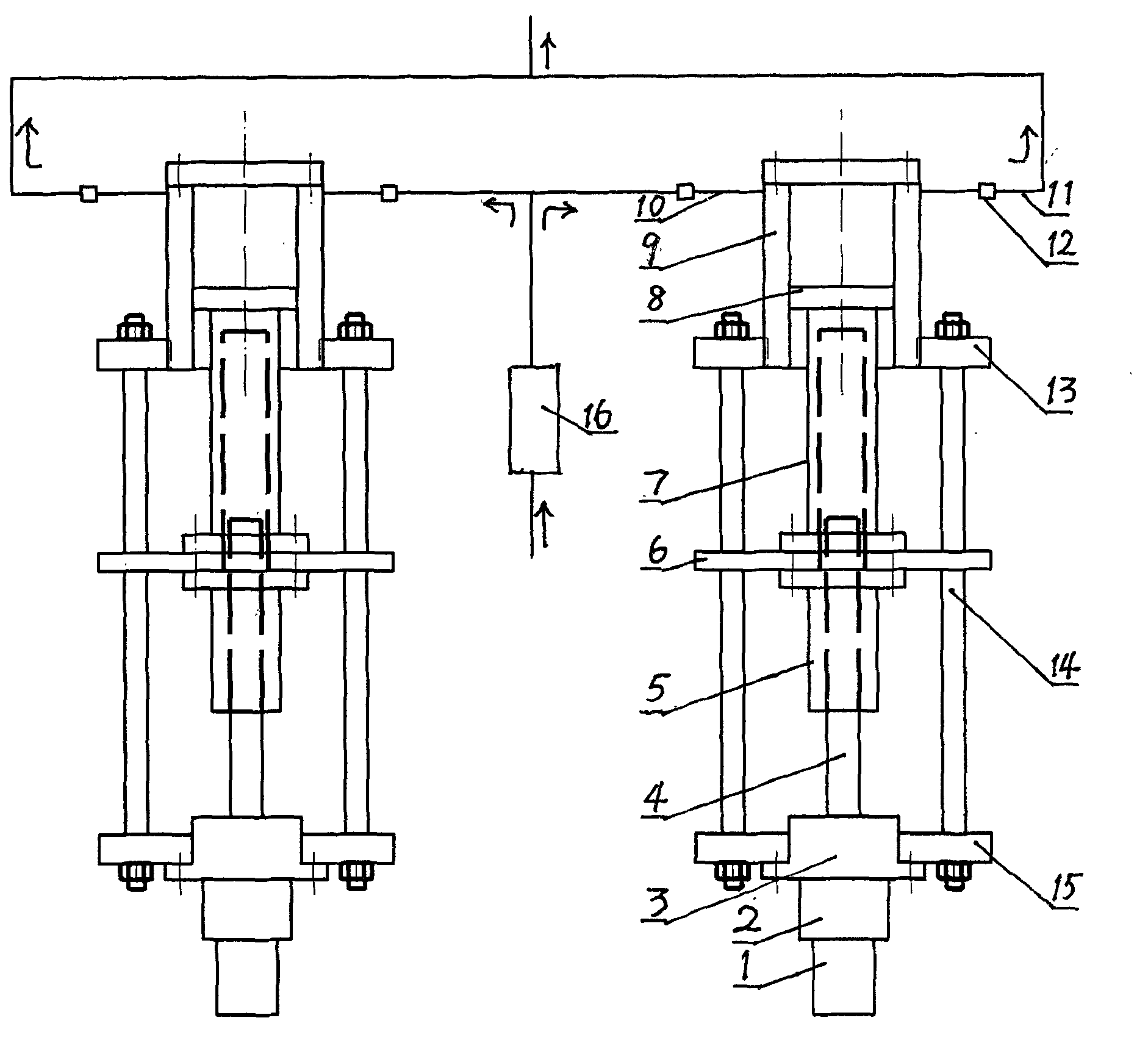

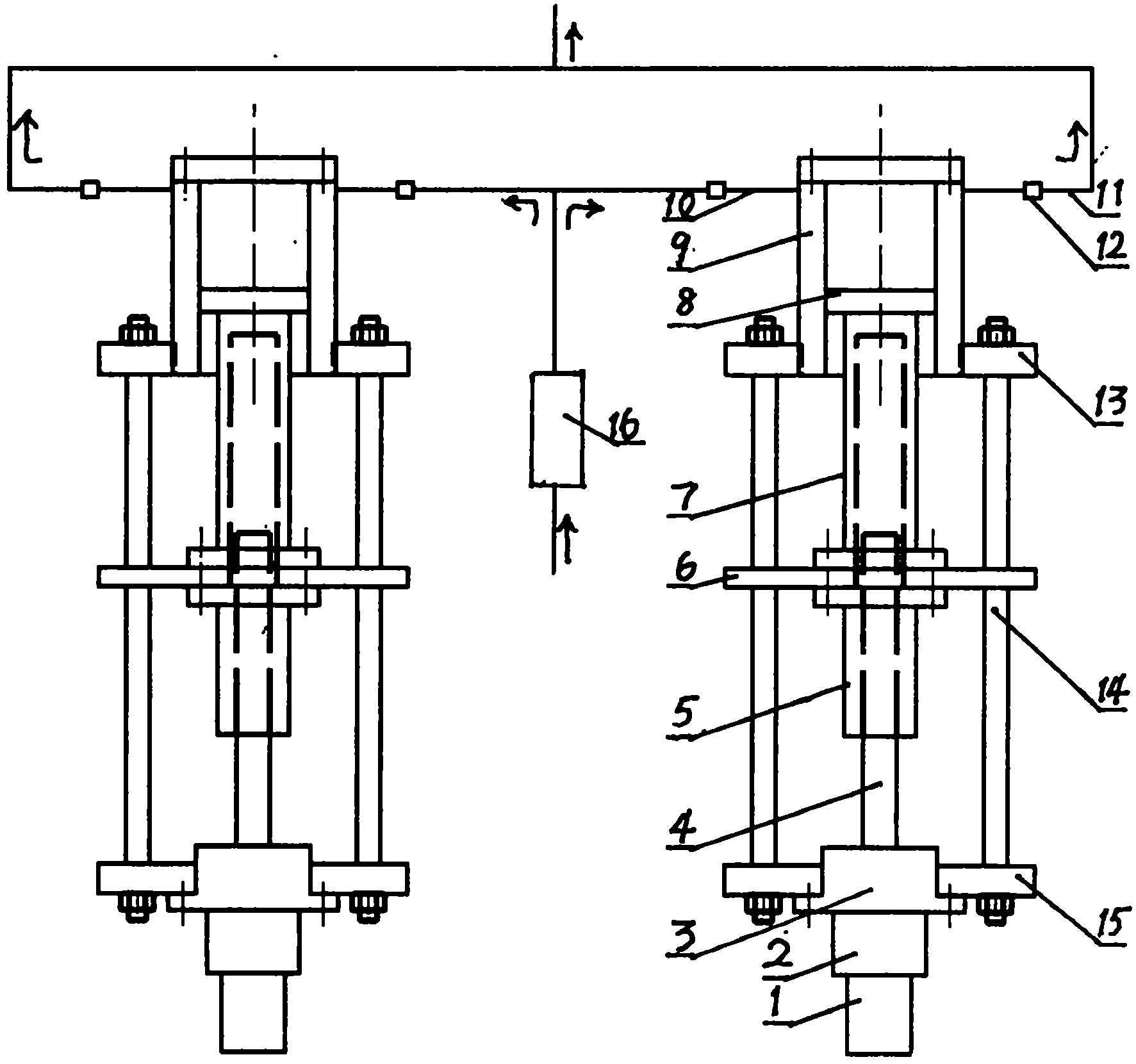

All-electric dual-cylinder linkage injection unit

An injection unit and electric technology, applied in the field of injection devices for liquid rubber injection molding, can solve the problems of difficulty in ensuring product quality, product cracking and scrapping, small injection volume, etc., and achieve good quality of finished products and quality of finished products. Stable, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the embodiments and with reference to the accompanying drawings: the accompanying drawings show the structure of an all-electric twin-cylinder linkage injection unit. This all-electric twin-cylinder linkage injection unit consists of two sets of injection units with the same structure. The sleeve injection unit includes a material cylinder 9, a piston 8, a feed pipe 10 and a discharge pipe 11. It is characterized in that the piston is connected with the ball screw nut 5 of the ball screw pair through the connecting sleeve 7, and the lower end of the ball screw shaft 4 is passed through the bearing. The seat 3 is connected with the precision planetary reduction box 2, and the latter is connected with the extension shaft of the servo motor 1, the upper horizontal plate 13 of the fixed material cylinder 9 and the lower horizontal plate 15 of the fixed bearing seat 3, and the two horizontal plates 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com