Extraction tank component

A technology of extraction tanks and components, applied in the direction of improving process efficiency, etc., can solve problems such as low construction efficiency and unstable construction quality, and achieve the effect of improving stability and good and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

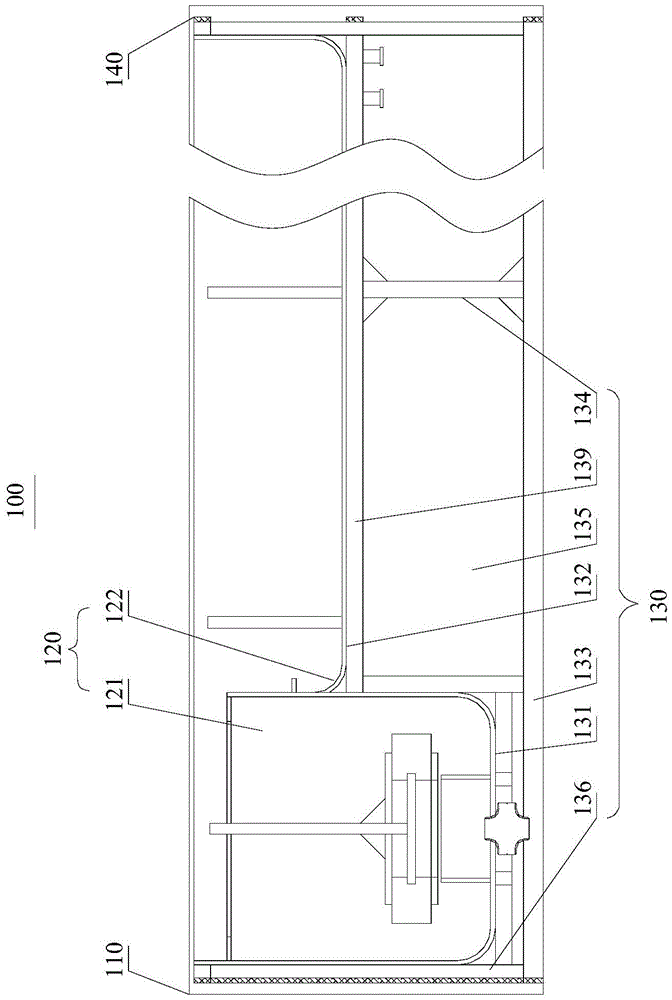

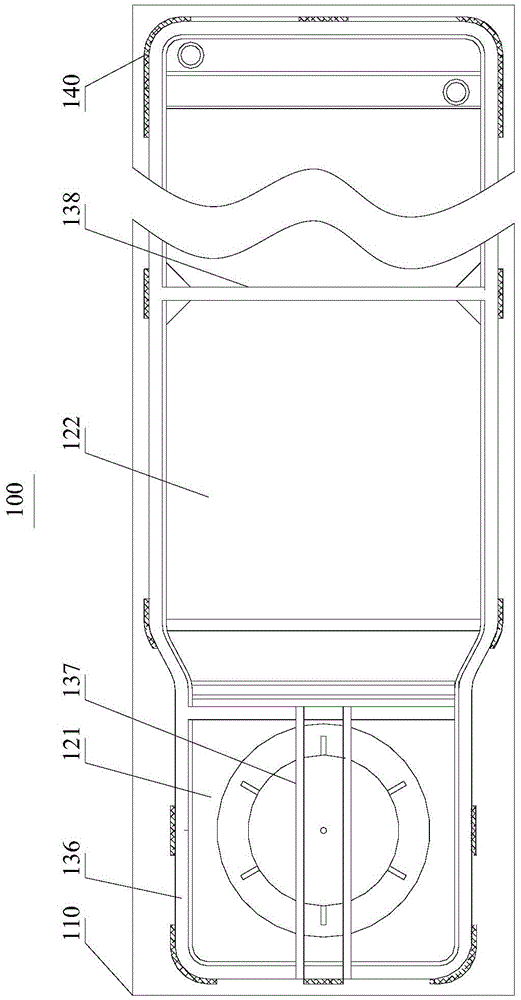

[0069] In the hydrometallurgical process, the extraction tank used for solvent extraction usually includes a settling chamber in which the aqueous solution and the organic solution are separated into various layers for separate discharge.

[0070] The inventor found in the process of realizing the present invention that the extraction production of large-scale hydrometallurgy is carried out in large-scale fixed extraction equipment, but for scattered mineral resources, small-scale extraction plants will be established, so that The extraction factories in China have been relocated due to changes in mineral resource raw materials and external conditions such as energy and transportation. However, since the extraction tank is usually built on site, its construction efficiency is low, its construction quality is unstable, and it is troublesome to dismantle when the factory is relocated. For small and medium-sized enterprises with small or variable resources and on-site leaching-ex...

Embodiment 2

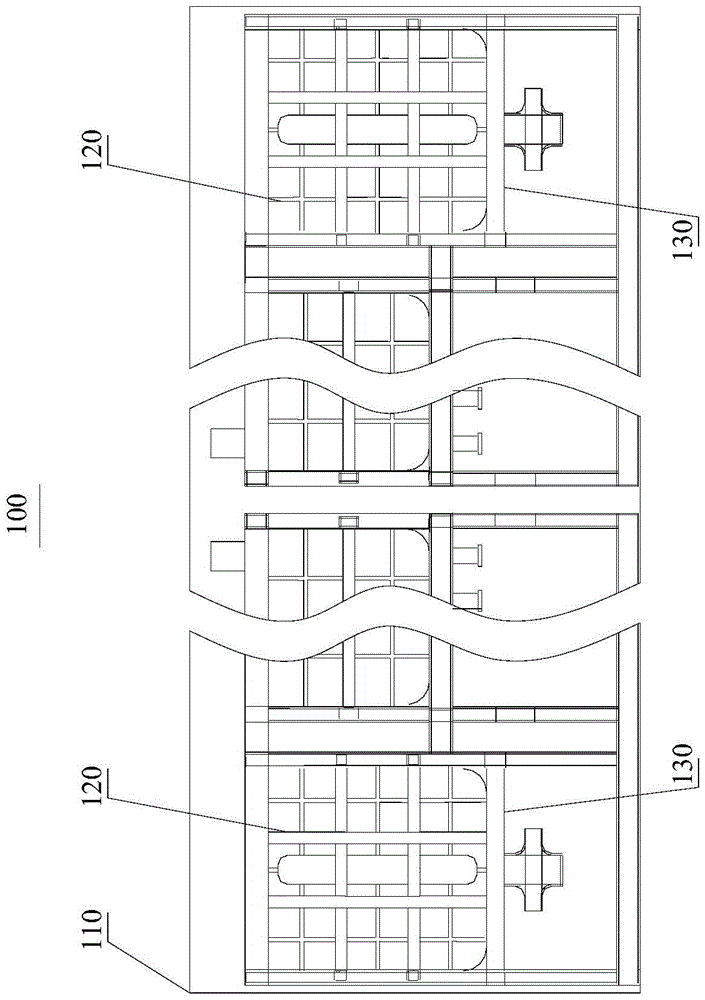

[0086] Such as image 3 with Figure 4 As shown, this embodiment is basically the same as the first embodiment, except that, for the extraction tank assembly 100 in this embodiment, four extraction tanks 120 and four support members 130 are arranged in one container 110 . In this embodiment, the dimensions of the extraction tank 120 and the support member 130 are smaller than those of the extraction tank 120 and the support member 130 in the first embodiment.

[0087] Four support members 130 are evenly arranged on the bottom surface of the container 110 , and each support member 130 supports an extraction tank 120 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com