Equipment and process for producing high-performance polyphenylene sulfide fine-denier fiber

A technology for polyphenylene sulfide and fine denier fiber, which is applied in the process of producing polyphenylene sulfide fine denier fiber and the field of polyphenylene sulfide fine denier fiber production equipment, can solve the problem that technical indicators such as strength and elongation are difficult to meet requirements , It is difficult to produce polyphenylene sulfide fine denier fibers, equipment and process requirements are high, so as to reduce the amount of oxygen entering, reduce the residence time, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

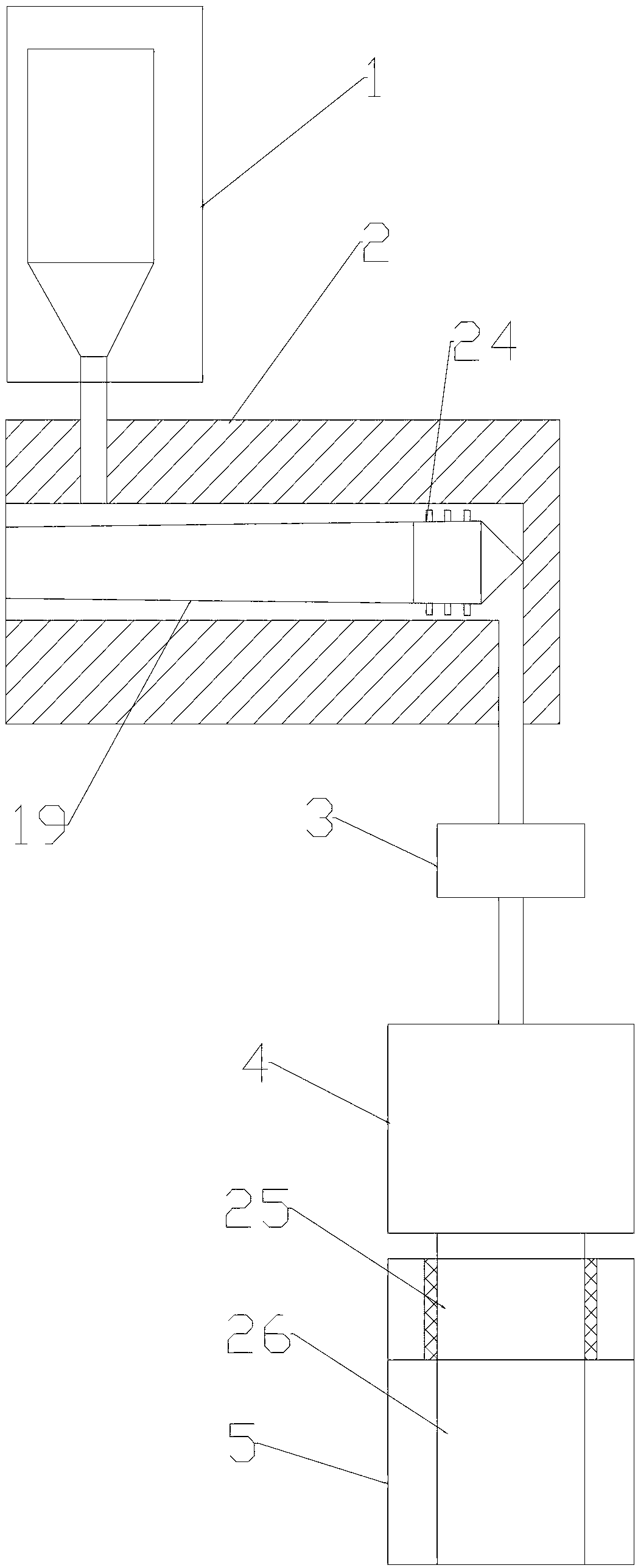

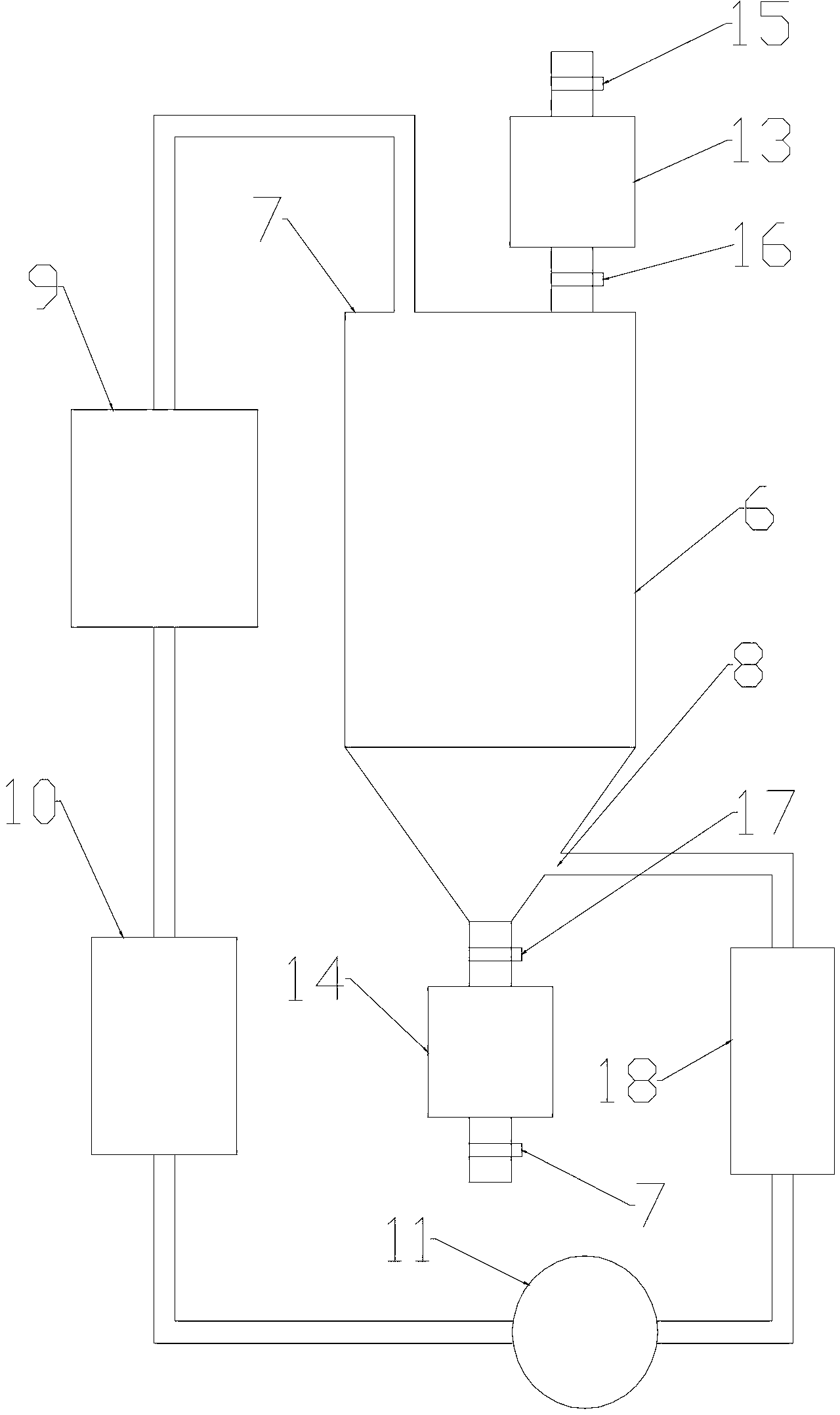

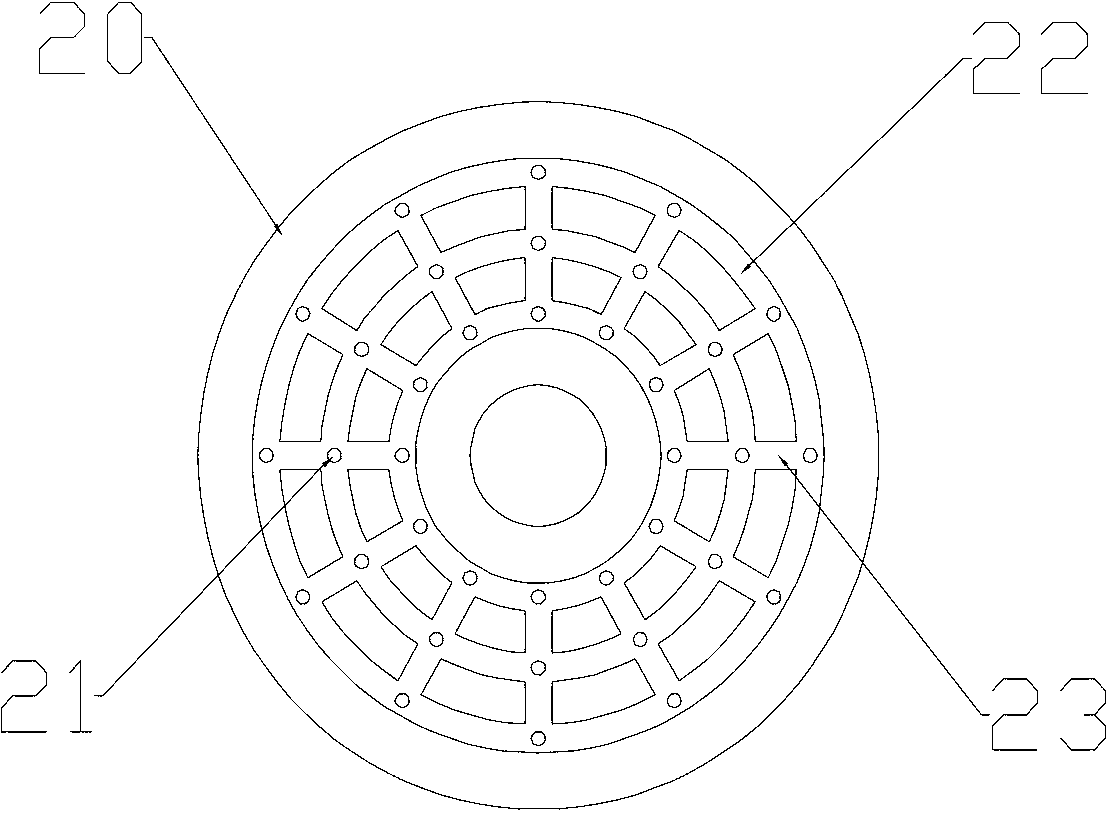

[0027] Such as figure 1 , figure 2 and image 3 As shown, a kind of high-performance polyphenylene sulfide fine-denier fiber production equipment of the present invention comprises a drying system 1, a screw extruder 2, a filter 3, a spinning machine 4 and a cooling device 5 connected in sequence, and the drying system 1 includes a drier 6, the air outlet 7 and the air inlet 8 of the drier 6 are closed and connected in sequence through a gas delivery pipe to a gas purification processor 9, a gas dehumidification processor 10, a fan 11, and a heater 12. The drying The feed port of the machine 6 is connected with an intermediate feed bin 13, and the discharge port of the dryer 6 is connected with an intermediate feed bin 14, and the feed port of the intermediate feed bin 13 is provided with a valve 15 and a discharge port. There is valve two 16, the feed port of the intermediate silo two 14 is provided with valve three 17, and the discharge port is provided with valve four 18...

Embodiment 2

[0029]A kind of technology that adopts the equipment in embodiment 1 of the present invention to produce high-performance polyphenylene sulfide fine denier fiber, comprises the following steps: A, material selection: select melting finger to be in 150-250g / min, molecular weight distribution in ± 2% scope The raw materials inside are cleaned of impurities; B, drying: the raw materials after cleaning are sent to the drying system for crystallization and drying at 100-170°C for 3-16 hours, so that the water content is less than 50ppm; C, melting: reuse The screw extruder is heated to 290-350°C for melting; D, spinning: after the melt impurities are filtered out by a filter, it is sent to the spinning machine for spinning under the condition of 350°C heat preservation and 2MPa pressure; E, cooling : After passing through the circular heating and slow cooling channel at 120°C, the sprayed filaments enter the circular air blowing channel under the conditions of 30°C and relative humi...

Embodiment 3

[0031] A kind of technology that adopts the equipment in embodiment 1 of the present invention to produce high-performance polyphenylene sulfide fine denier fiber, comprises the following steps: A, material selection: select melting finger to be in 150-250g / min, molecular weight distribution in ± 2% scope The raw materials inside are cleaned of impurities; B, drying: the raw materials after cleaning are sent to the drying system for crystallization and drying at 100-170°C for 3-16 hours, so that the water content is less than 50ppm; C, melting: reuse The screw extruder is heated to 290-350°C for melting; D, spinning: after the melt impurities are filtered out by a filter, it is sent to the spinning machine for spinning under the condition of 290°C heat preservation and 15MPa pressure; E, cooling : After passing through the circular heating and slow cooling channel at 80°C, the sprayed filaments enter the circular blowing channel at 20°C and relative humidity of 90 for cooling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com