Processing technology of chromium-zirconium-copper contact wire for high-speed electrified railway

A technology for electrified railways and processing technology, applied to circuits, electrical components, conductive materials, etc., can solve problems such as low production efficiency, high production cost, and long production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

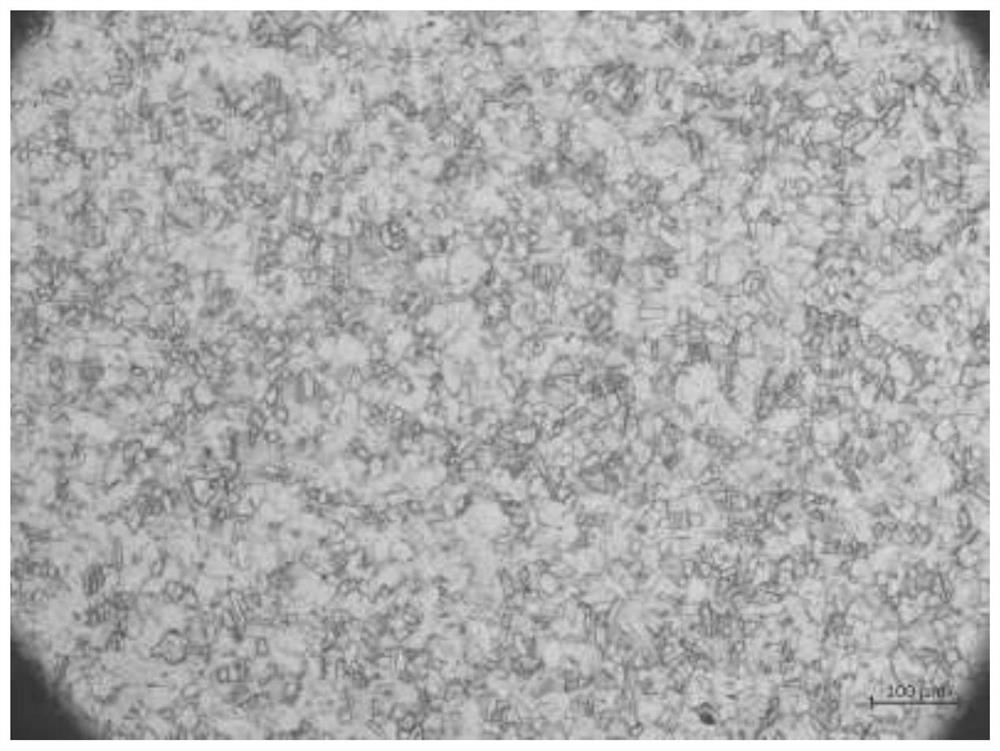

Image

Examples

Embodiment 1

[0025] A process for processing chromium-zirconium-copper contact wires for high-speed electrified railways, specifically carried out according to the following steps:

[0026] Step 1: Use upward continuous casting technology to obtain chromium-zirconium copper rods, use upward-oriented oxygen-free copper rods, copper-chrome core-covered wires, and copper-zirconium core-covered wires as raw materials, and cast chromium-zirconium copper rods on the upward vertical continuous casting machine Copper rods are drawn up and continuously cast to obtain upcast chromium-zirconium-copper copper rods whose composition satisfies Cr: 0.6%, Zr: 0.06%, and Cu: the balance, and the copper content of the uplinked oxygen-free copper rods is above 99.97%. , and the oxygen content is lower than 5ppm, and the uplifting speed is controlled to 1200mm / min, and the uplifting cast chromium-zirconium copper copper rod with a copper rod diameter of Φ25mm is selected as the copper rod disc round material; ...

Embodiment 2

[0034] The difference from the first embodiment is that:

[0035]Chromium-zirconium copper rods are obtained by adopting upward continuous casting technology. Using upward-oriented oxygen-free copper rods, copper-chrome core-covered wires, and copper-zirconium core-covered wires as raw materials, the chrome-zirconium copper rods are cast on vertical continuous casting machines. Leading and continuous casting to obtain an upward casting chromium-zirconium-copper copper rod whose composition satisfies Cr: 0.8%, Zr: 0.09%, and Cu: the balance. The copper content of the upward-leading oxygen-free copper rod is above 99.97%, and contains The oxygen content is lower than 5ppm, and the uplift speed is controlled at 800mm / min. The uplift casting chromium-zirconium copper copper rod with a copper rod diameter of Φ25mm is selected as the round material for the copper rod.

[0036] Get: the cross-sectional area is 121mm 2 , Tensile strength: 670Mpa, softening rate: 95%, elongation: 6%, ...

Embodiment 3

[0038] The difference from the second embodiment is that:

[0039] Chromium-zirconium copper rods are obtained by adopting upward continuous casting technology. Using upward-oriented oxygen-free copper rods, copper-chrome core-covered wires, and copper-zirconium core-covered wires as raw materials, the chrome-zirconium copper rods are cast on vertical continuous casting machines. Leading and continuous casting to obtain an upward casting chromium-zirconium-copper copper rod whose composition satisfies Cr: 1.0%, Zr: 0.2%, and Cu: the balance. The copper content of the upward-leading oxygen-free copper rod is above 99.97%, and contains The oxygen content is lower than 5ppm, and the uplift speed is controlled at 800mm / min. The uplift casting chromium-zirconium copper copper rod with a copper rod diameter of Φ30mm is selected as the round material for the copper rod.

[0040] Step 4: rolling the round rod material obtained from step 3 after solution heat treatment, and rolling the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sectional area | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com