Wheat milling process

A process and wheat technology, applied in the field of wheat flour milling technology, can solve the problems of affecting the quality of flour, deterioration during storage, affecting the color of flour, etc., and achieve the effects of excellent and stable quality, simple unit combination and high flour yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

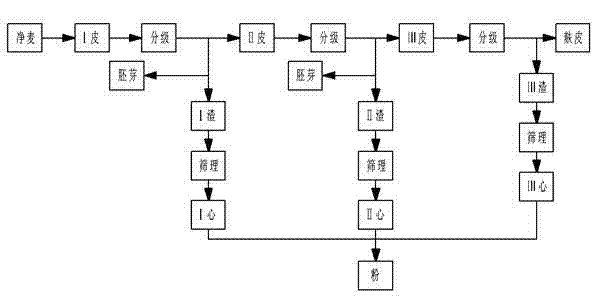

[0012] like figure 1 The present invention is further described as shown.

[0013] A wheat flour milling process is carried out according to the following steps: the clean wheat that has been cleaned and moistened, with a water content of 14.4-14.8%, is put into the I skin mill, and then coarsely screened to separate the skin from the wheat germ and the heart. Afterwards, the skin enters the skin mill II, the heart enters the slag mill I, and collects wheat germ; after the heart enters the slag mill I, it is screened to separate the skin from the heart, and the heart enters the heart mill I;

[0014] After the skins separated by I skin mill enter II skin mill, coarse sieve is carried out to separate the skin, wheat germ and heart. After separation, the skin enters III skin mill and wheat germ is collected; after the heart enters II slag mill, it is sieved , separate the skin from the heart, and the heart enters into the second heart mill;

[0015] After the skins separated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com