Method for bending large-diameter pipelines through fire

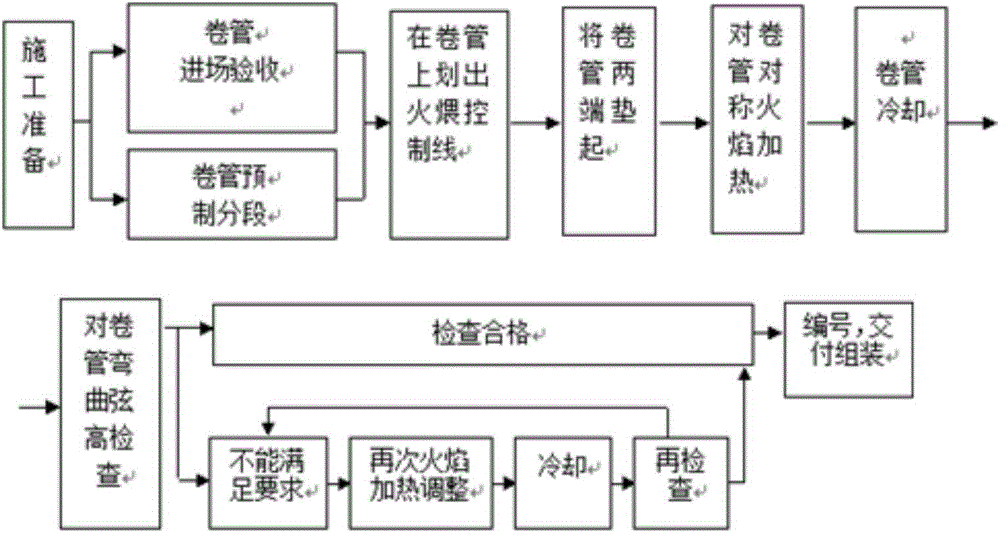

A large-diameter, simmer-bending technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of pipeline difficulty, hidden dangers in construction, and high requirements for equipment, so as to simplify construction procedures, save construction costs, and make equipment simple and light. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

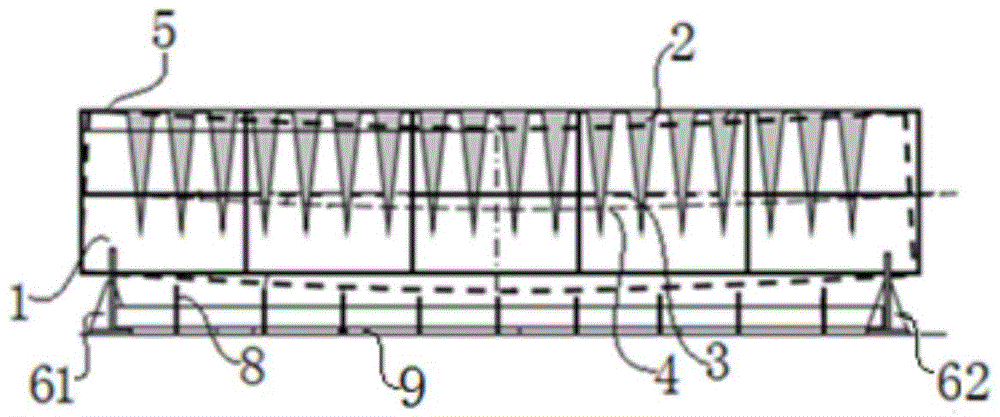

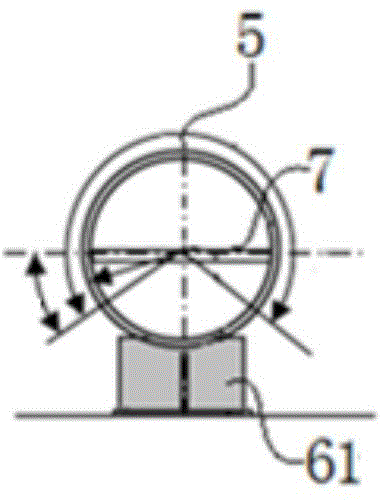

[0038] There are two methods for bending large steel components: cold bending and hot bending. Due to factors such as the volume of large steel components and the use of machinery, most of them use the hot-simmer bending process, and the hot-simmer bending process is also subdivided into several types: using a large-caliber intermediate-frequency bending machine to bend, heating first and then extruding the bend , Partial simmering and extrusion molding first, and then integral welding of elbows, etc. Although the existing hot bending technology can achieve the purpose of bending large steel components, the disadvantages are also very obvious: it is necessary to use large equipment, such as: intermediate frequency bending machine, hydraulic jack, infrared temperature measuring instrument, etc. It is worth noting that many construction areas are very remote. These large-scale equipment are either difficult to transport or the transportation cost is high, which brings great inco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com