Low-cement-sand-ratio anti-cracking Portland cement adhesive for insulator

A cement adhesive and Portland cement technology, which can be used in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of reducing dry shrinkage, improving fluidity and compressive strength, and improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

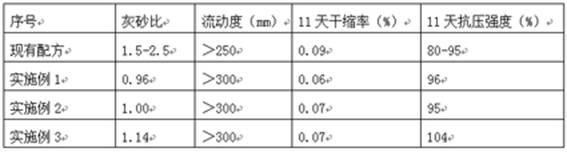

Examples

Embodiment 1

[0013] Embodiment 1: This embodiment is a low lime-sand ratio anti-crack Portland cement adhesive for insulators. The adhesive is composed of the following components in weight percentage: Portland cement 39.37%, glued sand 41.16%, glue Use SiO for sand filling 2 Natural sand with a content of 94%, zirconium-containing silica fume 1.84%, blast furnace slag powder 3.82%, expansion agent 2.04%, polyacrylonitrile fiber with a fiber length of 5mm 0.036%, water reducing agent 0.15%, water retention agent 0.01%, water 11.57 %, defoamer 0.004%.

[0014] Portland cement is 52.5 Portland cement.

[0015] SiO in zirconium silica fume 2 The content is 95.1%.

[0016] The specific surface area of blast furnace slag powder is 800m 2 / kg.

[0017] The water-reducing agent is a high-water-reducing polycarboxylate water-reducer, and the weight percentage of the high-water-reducing polycarboxylate water-reducer in the adhesive is 0.15%.

Embodiment 2

[0018] Example 2: This implementation is a low-lime-sand ratio anti-crack Portland cement adhesive for insulators. The adhesive is composed of the following components in weight percentage: Portland cement 41.08%, glued sand 41.22%, glued Sand chooses SiO 2 Processed sand with a content of 99%, zirconium-containing silica fume 2.05%, blast furnace slag powder 3.38%, polyacrylonitrile fiber with a fiber length of 6mm 0.045%, water reducing agent 0.16%, water retaining agent 0.03%, water 12.06%, defoamer 0.005%.

[0019] Portland cement is 52.5R Portland cement.

[0020] SiO in zirconium silica fume 2 The content is 94.2%.

[0021] The specific surface area of blast furnace slag powder is 1000m 2 / kg.

[0022] Water-reducing agents include high-water-reducing polycarboxylate water-reducers and slump-retaining polycarboxylate water-reducers. Among them, the weight percentage of high-water-reducing polycarboxylate water-reducers in the cement is 0.13%, and the slump-retaini...

Embodiment 3

[0023] Embodiment 3: This embodiment is a low lime-sand ratio anti-crack Portland cement adhesive for insulators. The adhesive is composed of the following components in weight percentage: Portland cement 42.79%, glued sand 37.65%, glue Use SiO for sand filling 2 Natural sand with a content of 94%, silica fume containing zirconium 2.28%, blast furnace slag powder 3.79%, expansion agent 1.82%, polyacrylonitrile fiber with a fiber length of 4mm 0.046%, water reducing agent 0.17%, water 11.45%, defoamer 0.004%.

[0024] Portland cement is 52.5R Portland cement.

[0025] SiO in zirconium silica fume 2 The content is 95.1%.

[0026] The specific surface area of blast furnace slag powder is 800m 2 / kg.

[0027] The water reducing agent includes high water-reducing polycarboxylate superplasticizer and slump-retaining polycarboxylate water-reducing agent. The weight percentage of polycarboxylate water reducer in the adhesive is 0.03%.

[0028] In actual application, Portland ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com