Preparation method of modified limestone powder for mass concrete

A technology for mass concrete and limestone powder, applied in the field of concrete materials, can solve the problems of large workability loss, low activity and low strength of concrete, and achieve the effects of reducing surface cracking, improving economic value, and reducing the temperature difference between inside and outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

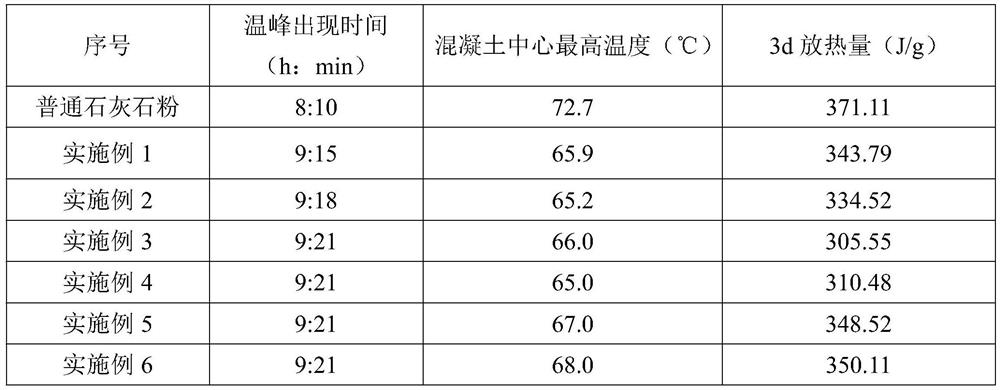

Examples

Embodiment 1

[0030] Dissolve 50g of limestone powder in 200ml of absolute ethanol, add 50g of KH570 and stir at 80°C for 1h; cool down to 65°C, add 242g of prenol polyoxyethylene ether, add 1g of ammonium persulfate, stir for 1.5h, and cool down to room temperature ; Add 0.5 g of PEG-PCL copolymer with a molecular weight of 20,000, stir at high speed for 1 hour, and dry to obtain modified limestone powder.

Embodiment 2

[0032] Dissolve 50g of limestone powder in 200ml of absolute ethanol, add 50g of KH550 and stir at 80°C for 1.5h; cool down to 65°C, add 242g of prenol polyoxyethylene ether, add 1g of ammonium persulfate and stir for 1.5h, drop to Room temperature; add 2.5 g of PEG-PBLA copolymer with a molecular weight of 20,000, stir at high speed for 1 hour, and dry to obtain modified limestone powder.

Embodiment 3

[0034] Dissolve 50g of limestone powder in 200ml of absolute ethanol, add 50g of KH570 and stir at 80°C for 2h; cool down to 65°C, add 242g of hydroxybutyl vinyl ether, add 1g of ammonium persulfate and stir for 1.5h, then cool down to room temperature; add 2.5 g of PEG-PCL copolymer with a molecular weight of 20,000 was stirred at high speed for 1 hour, and dried to obtain modified limestone powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com