Composite admixture applied to hydraulic concrete and preparation method thereof

A technology of hydraulic concrete and composite admixture, which is applied in cement production, sustainable waste treatment, solid waste management, etc., can solve the problems of hydration heat control and rust prevention at the same time, and achieve the reduction of temperature shrinkage cracks, Reduce the temperature difference and reduce the effect of early heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

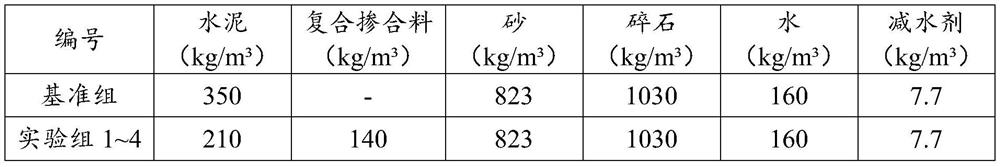

Method used

Image

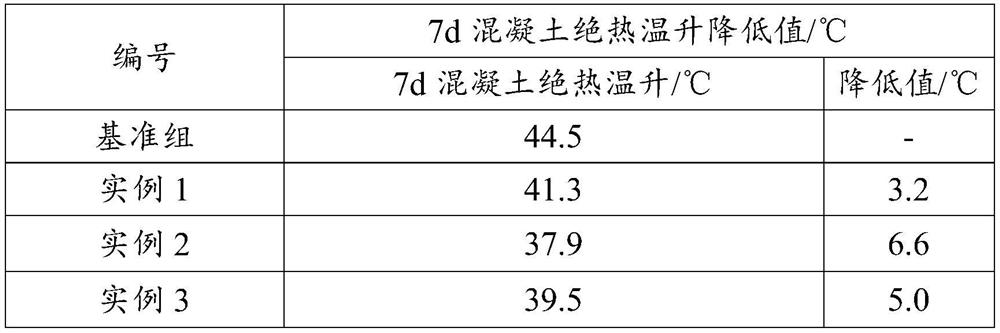

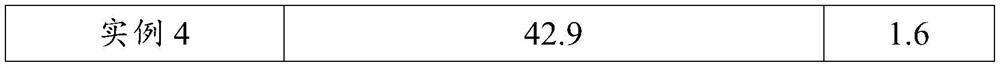

Examples

preparation example Construction

[0022] In order to solve the above technical problems, the present invention provides a second solution: a method for preparing a composite admixture applied to hydraulic concrete is provided, which is used to prepare the composite admixture applied to hydraulic concrete in the aforementioned first solution Admixtures, the specific steps are as follows:

[0023] After taking mineral powder, manganese slag powder, phosphogypsum powder and silica fume according to the proportion, stir and premix for 1-2 minutes to obtain the first mixture; ~3 minutes to obtain the second mixture; add the second mixture into the first mixture according to the ratio, and stir evenly to obtain a composite admixture for hydraulic concrete.

[0024] In addition, after obtaining the composite admixture applied to hydraulic concrete, the composite admixture is applied to hydraulic concrete instead of the cementitious material in the cement base material, so that the hydraulic concrete has both hydratio...

Embodiment 1

[0031]In this embodiment, the following raw materials are weighed in terms of mass percentages: 45% mineral powder, 35% manganese slag powder, 3.9% phosphogypsum powder, 15% silica fume, 0.95% sodium citrate, diethanol monoisopropanolamine 0.05%, sodium monofluorophosphate 0.05%, sodium gluconate 0.05%; among them, sodium citrate is the heat of hydration inhibitor component, and the mixture of diethanol monoisopropanolamine, sodium monofluorophosphate and sodium gluconate is the rust inhibitor components.

[0032] Stir and premix mineral powder, manganese slag powder, phosphogypsum powder, and silica fume for 1 minute to obtain the first mixture; stir and premix the pre-prepared hydration heat suppression component and antirust component for 2 minutes to obtain the second Mixed material: adding the second mixed material into the first mixed material, and stirring evenly to obtain a composite admixture applied to hydraulic concrete.

Embodiment 2

[0034] In this embodiment, the following raw materials are weighed in terms of mass percentages: 45% mineral powder, 35% manganese slag powder, 3% phosphogypsum powder, 13.95% silica fume, 1.0% sodium citrate, 1.90% sodium fluorosilicate, 0.05% diethanol monoisopropanolamine, 0.05% sodium monofluorophosphate, 0.05% sodium gluconate; among them, sodium citrate and sodium fluorosilicate are heat of hydration inhibiting components, diethanol monoisopropanolamine, mono The mixture of sodium fluorophosphate and sodium gluconate is an antirust component.

[0035] The mineral powder, manganese slag powder, phosphogypsum powder, and silica fume were stirred and premixed for 2 minutes to obtain the first mixture; the pre-prepared hydration heat suppression component and antirust component were stirred and premixed for 2 minutes to obtain the second mixture. Mixed material: adding the second mixed material into the first mixed material, and stirring evenly to obtain a composite admixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com