A preparation method of a large amount of wet-grinding phosphorus solid waste ultra-retarded gelling material

A cementitious material, ultra-retarding technology, applied in the field of building materials, can solve the problem of only 28-day strength, achieve high strength in the later stage, increase the dosage, and have obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

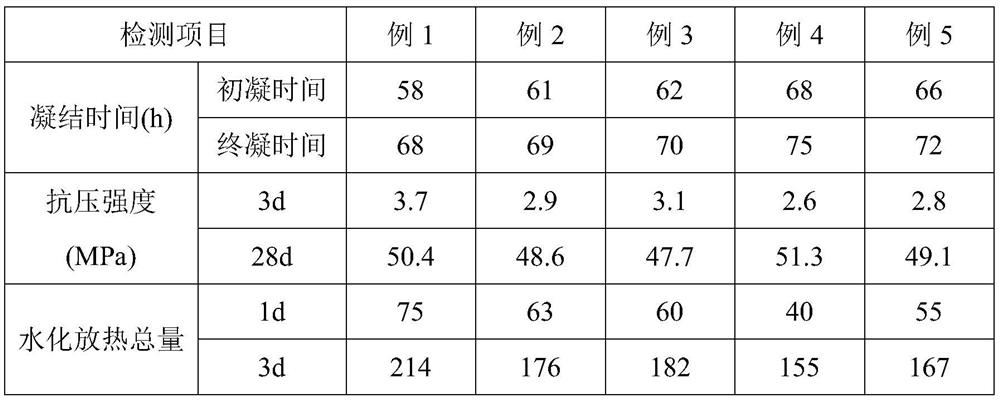

Examples

Embodiment 1

[0038] 1) Take 200 parts by weight of phosphorus slag and send 20 parts of desulfurization ash into a wet ball mill, add water according to the ratio of water to material mass ratio of 0.4, and obtain mixed slurry A;

[0039] The average particle size of the mixed slurry A is 4 μm;

[0040] 2) Take 5 parts by weight of alkali slag, 2 parts of phosphogypsum, and 4 parts of fly ash and grind them with a dry mill to obtain a mixed powder material B;

[0041] The average particle size of the mixed powder material B is 9 μm;

[0042] 3) Mix the mixed slurry A with the mixed powder material B to obtain the mixed material C, add 5 parts of cement, 0.5 parts of water-soluble resin sulfonate water reducing agent, 0.5 parts of sodium pyrophosphate, 150 1 part of tailings sand, 300 parts of gravel, stirred for 4 minutes to obtain super retarded concrete;

[0043] The phosphorus slag P 2 o 5 The content of F is 2.5%, and the content of F is 1.9%.

Embodiment 2

[0045] 1) Take 230 parts by weight of phosphorus slag and 25 parts of desulfurized ash and send them into a wet ball mill, add water according to the ratio of water to material mass ratio of 0.4, and obtain mixed slurry A;

[0046] The average particle size of the mixed slurry A is 3.2 μm;

[0047] 2) Take 7 parts by weight of alkali slag, 8 parts of phosphogypsum, and 10 parts of fly ash and grind them with a dry mill to obtain a mixed powder material B;

[0048] The average particle size of the mixed powder material B is 8.5 μm;

[0049] 3) Mix the mixed slurry A with the mixed powder material B to obtain the mixed material C, add 10 parts of cement, 0.5 parts of water-soluble resin sulfonate water reducing agent, 0.5 parts of sodium pyrophosphate, 0.5 parts of 1 part of phosphate, 100 parts of tailings sand, 250 parts of gravel, and stirred for 4 minutes to obtain super retarded concrete.

[0050] The phosphorus slag P 2 o 5 The content of F is 3%, and the content of F ...

Embodiment 3

[0052] 1) Take 260 parts by weight of phosphorus slag and 25 parts of desulfurization ash and send them into a wet ball mill, add water according to the ratio of water to material mass ratio of 0.45, and obtain mixed slurry A;

[0053] The average particle size of the mixed slurry A is 2.4 μm;

[0054] 2) Take 10 parts by weight of alkali slag, 8 parts of phosphogypsum, and 8 parts of fly ash and grind them with a dry mill to obtain a mixed powder material B;

[0055] The average particle size of the mixed powder material B is 7 μm;

[0056] 3) Mix the mixed slurry A with the mixed powder material B to obtain the mixed material C, add 15 parts of cement, 0.5 parts of water-soluble resin sulfonate water reducing agent, 0.7 parts of phosphate, 200 parts of Tailings sand, 400 parts of gravel, stirred for 4 minutes to obtain super retarded concrete.

[0057] The phosphorus slag P 2 o 5 The content of F is 3.5%, and the content of F is 2.9%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com