C50 self-compacting concrete for bridges and its preparation method

A self-compacting concrete and concrete technology, applied in the field of building materials, can solve the problems of low elastic modulus and high-quality mineral admixtures, and achieve the effects of alleviating construction noise pollution, shortening the construction period, and increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

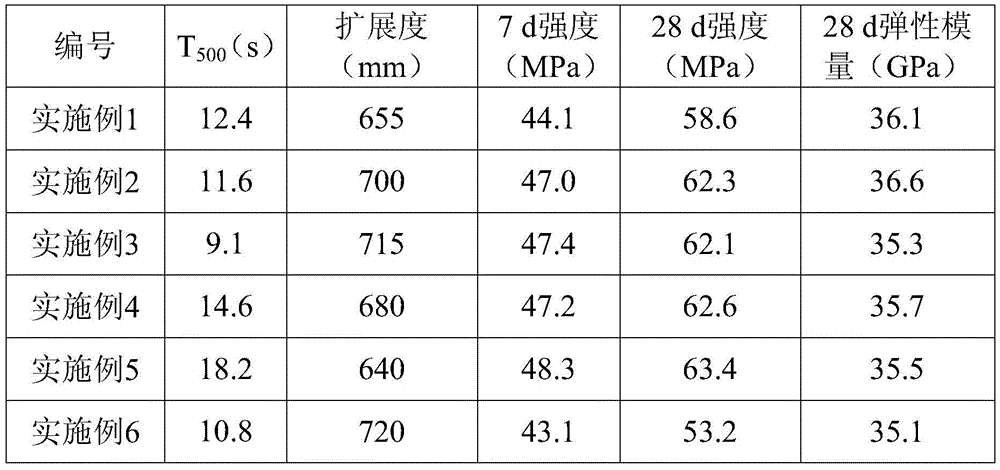

Examples

Embodiment 1

[0023] Take 357kg of P·II cement, 153kg of secondary fly ash, 774kg of medium sand with a fineness modulus of 2.3 and a mud content of less than 1.0% and stir for 0.5min. The 45μm square hole sieve residue of the secondary fly ash is not more than 25%, loss on ignition is not more than 8%, water demand is not more than 105%; add Stir 6.36kg of water reducing agent and 163kg of water for 1min, then put in 946kg of crushed stone with a particle size range of 5-20mm, continuous grading, mud content less than 0.5%, stir for 2min, stir and form to prepare C50 self-compacting concrete for bridge .

Embodiment 2

[0025] Take 371kg of P·II cement, 159kg of secondary fly ash, and 762kg of medium sand with a fineness modulus of 2.5 and a mud content of less than 1.0% and stir for 0.5min. The 45μm square-hole sieve residue of the secondary fly ash is not more than 25%, the loss on ignition is not more than 8%, and the water demand is not more than 105%; add 6.36kg of SKD-14 water reducing agent and 170kg of water, stir for 1min, and then put in the particle size range of 5-20mm, continuous gradation, mud content 932kg of crushed stone of less than 0.5% was mixed for 2 minutes, and then mixed and formed into C50 self-compacting concrete for bridge.

Embodiment 3

[0027] Take 385kg of P·II cement, 165kg of secondary fly ash, 750kg of medium sand with a fineness modulus of 2.8 and a mud content of less than 1.0% and stir for 0.5min. The 45μm square hole sieve residue of the secondary fly ash is not more than 25%, the ignition loss is not more than 8%, and the water demand is not more than 105%; add HP400 water reducing agent 7.7kg and water 176kg and stir for 1min, then put in the particle size range of 5-20mm, continuous grading, and the mud content is less than 0.5 % Of crushed stone is 917kg, mixed for 2min, and then formed into a C50 self-compacting concrete for bridge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com