A kind of admixture suitable for reducing hydration heat of mass concrete and preparation method thereof

A large-volume concrete and admixture technology, applied in the field of concrete building materials, can solve the problems of narrow phase transition temperature range, single phase transition system, and limited application environment range of hydration heat materials, so as to improve water reduction effect and phase transition volume Minimal change, reduced surface cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The admixture suitable for reducing the hydration heat of large-volume concrete prepared in this example comprises, in parts by weight, 60% by weight of double bond-containing polyether monomer, 15% by weight of unsaturated carboxylic acid monomer, and 3% by weight of propylene glycol , trimethylolaminomethane 18wt%;

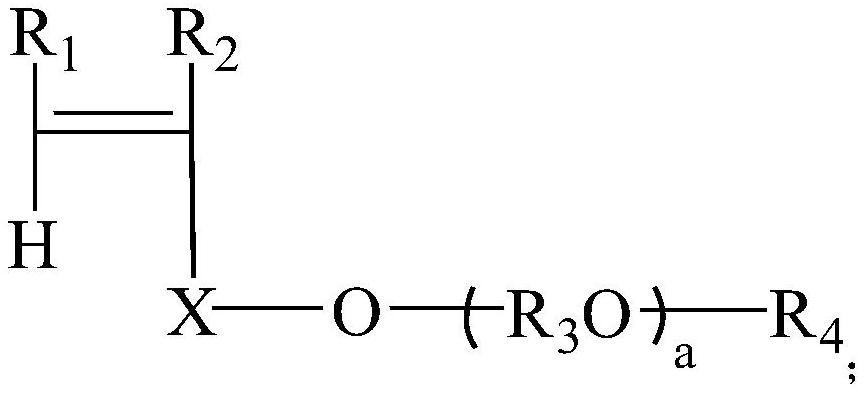

[0060] In the chemical structural formula of the double bond-containing polyether monomer, R 1 is a hydrogen atom, R 2 is methyl; X is an alkyl group of 2 carbon atoms; R 3 O is an alkoxy group with 2 carbon atoms, a=54, R 4 is a hydrogen atom;

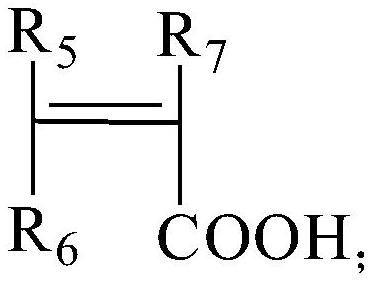

[0061] In the chemical structural formula of the unsaturated carboxylic acid monomer, R 5 is a hydrogen atom, R 6 is a carboxyl group, R 7 is methyl;

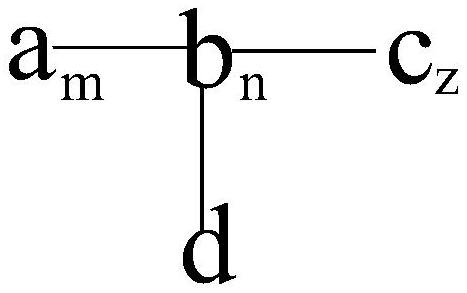

[0062] In the chemical structural formula of the admixture, m and z are respectively 10, and n is 50.

Embodiment 2

[0064] The admixture suitable for reducing the hydration heat of large-volume concrete prepared in this example includes, in parts by weight, 75wt% of double bond-containing polyether monomer, 10wt% of unsaturated carboxylic acid monomer, and 3wt% of methallyl alcohol %, 5-amino-1-hydroxymethyl-cyclohexyl-1,2,3,4-tetraol 12wt%;

[0065] In the chemical structural formula of the double bond-containing polyether monomer, R 1 and R 2 Each is an alkyl group of 5 carbon atoms; X is a methylene group; R 3 O is an alkoxy group of 5 carbon atoms, a=50, R 4 is an alkyl group of 2 carbon atoms;

[0066] In the chemical structural formula of the unsaturated carboxylic acid monomer, R 5 , R 6 , R 7 is methyl;

[0067] In the chemical structural formula of the admixture, m and z are respectively 50, and n is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com