Laser-assisted orthogonal micro-cutting device and method having automatic laser focus following function

A laser-assisted, automatic follow-up technology, applied in laser welding equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of inability to monitor the height change of the surface to be processed in real time, reduce vibration, improve processing accuracy, ensure The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

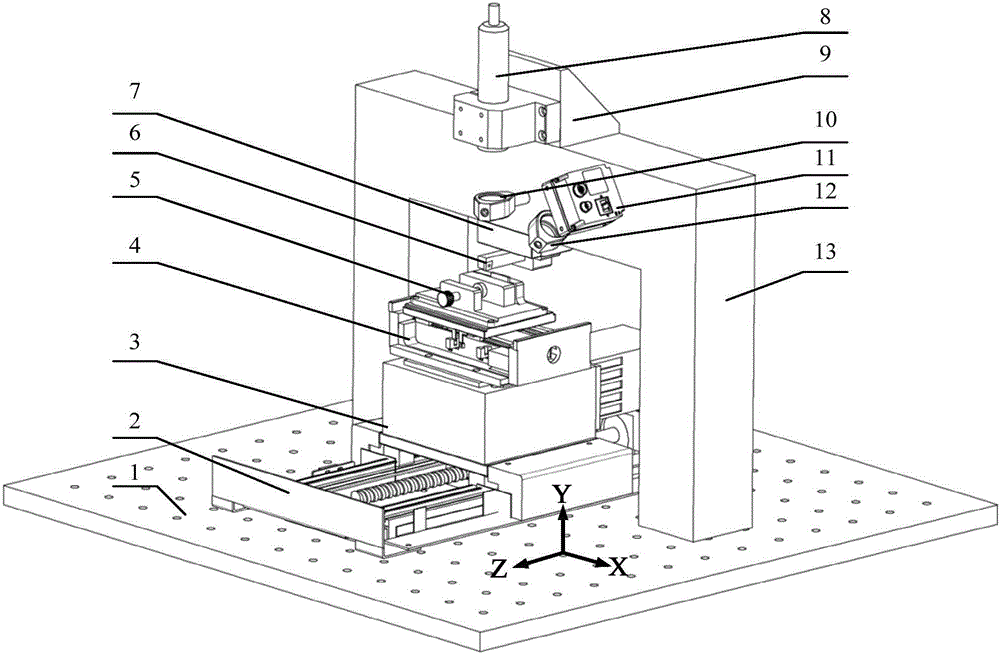

[0037] See attached figure 1 , the laser-assisted orthogonal micro-machining device with laser focus automatic following of the present invention comprises a shock absorption platform 1, a motion unit, a laser-assisted processing unit, an optical automatic following unit and a computer control unit;

[0038] The motion unit is installed on the shock-absorbing platform 1, the gantry support frame 13 of the laser-assisted processing unit is fixed on the shock-absorbing platform 1, and the optical automatic follower unit is arranged on the gantry support of the laser-assisted processing unit. on rack 13;

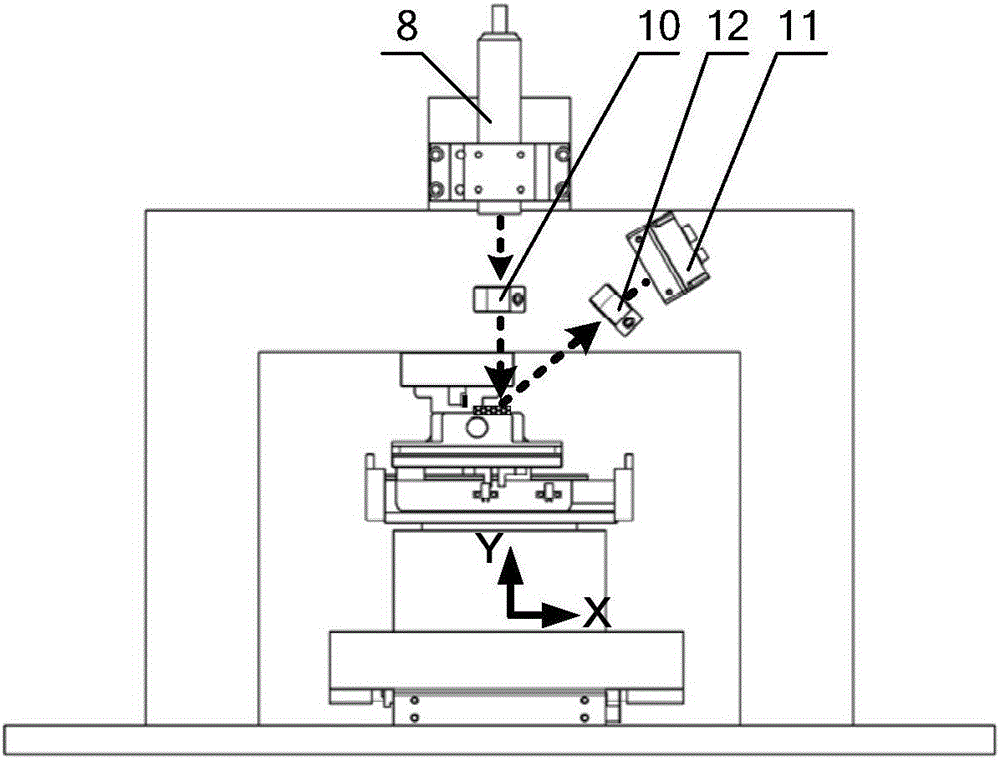

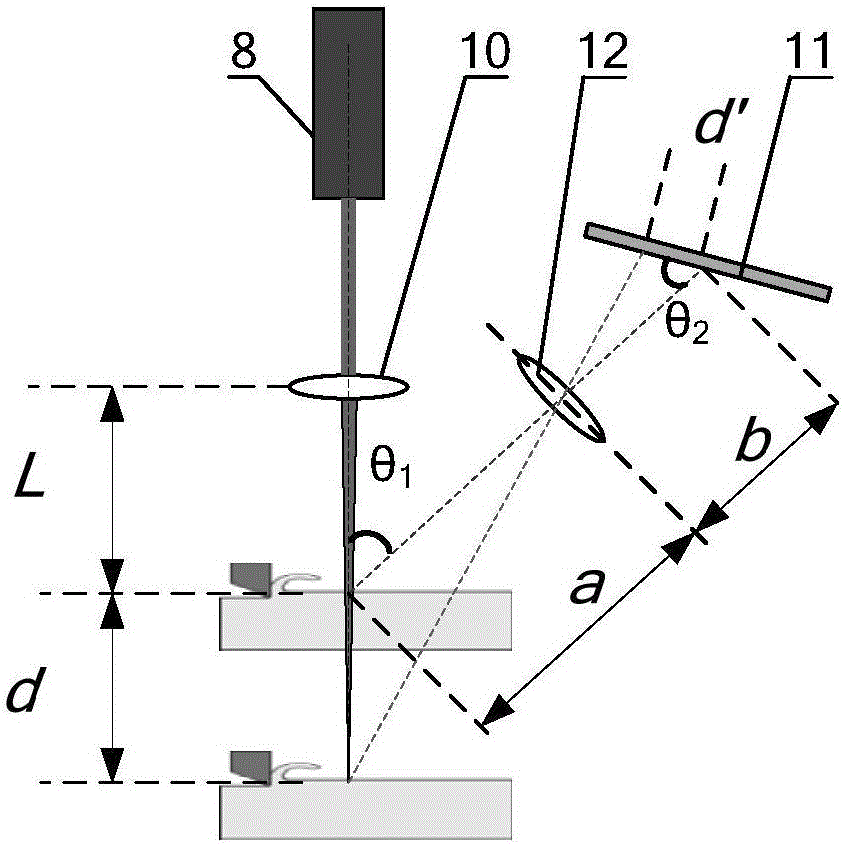

[0039] The optical automatic follow-up unit includes a lens A10, a lens B12 and a linear CCD sensor 11; the laser light emitted by the laser light source 8 in the laser auxiliary processing unit is irradiated to the front end of the tool along the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com