Glass fiber reinforced silicon dioxide aerogel composite material and preparation method thereof

A glass fiber and silica technology is applied in the field of preparing glass fiber reinforced silica aerogel composite materials, which can solve the problem that the material properties need to be further optimized, and achieve the effects of avoiding excessive volume shrinkage, strengthening strength, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

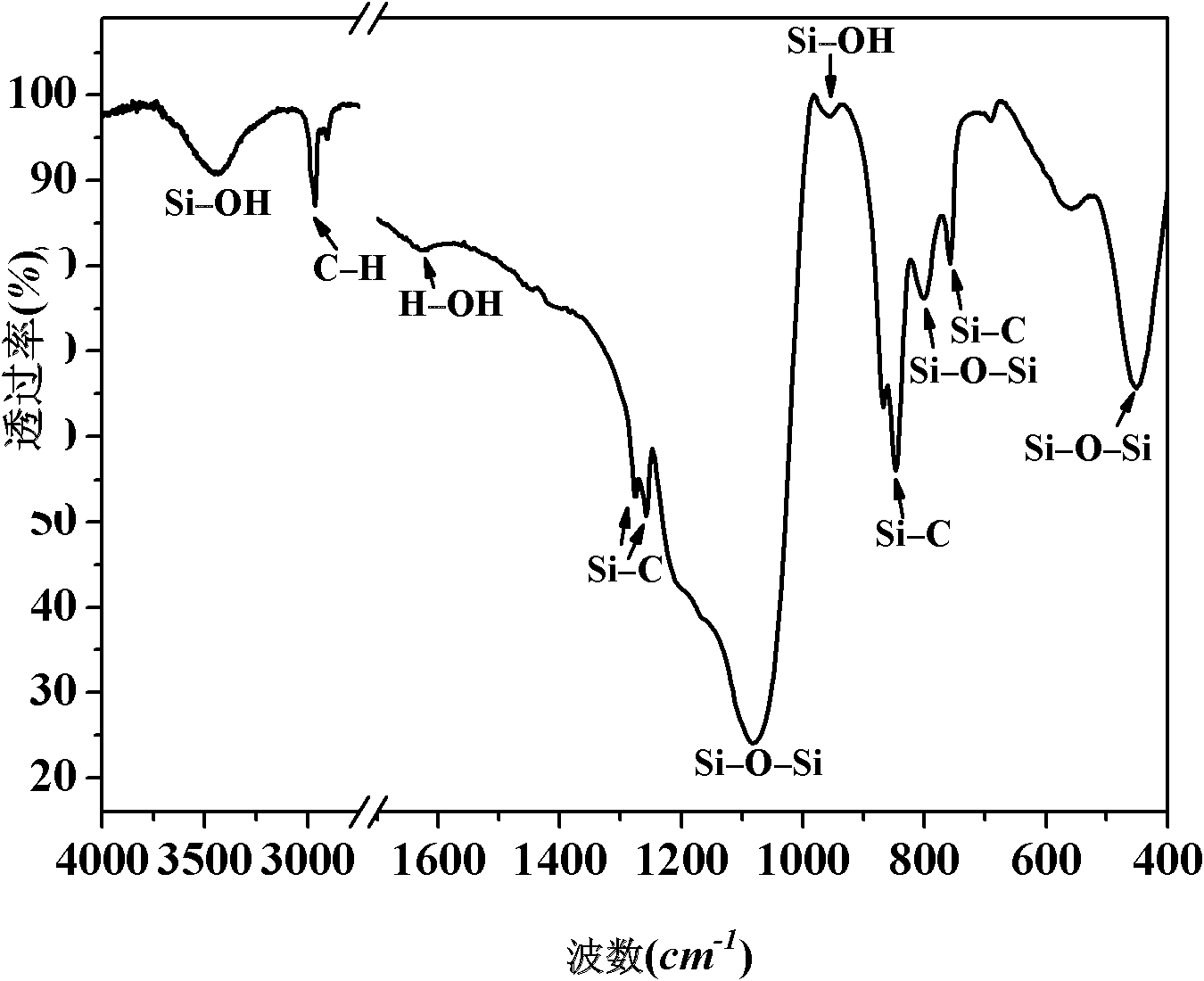

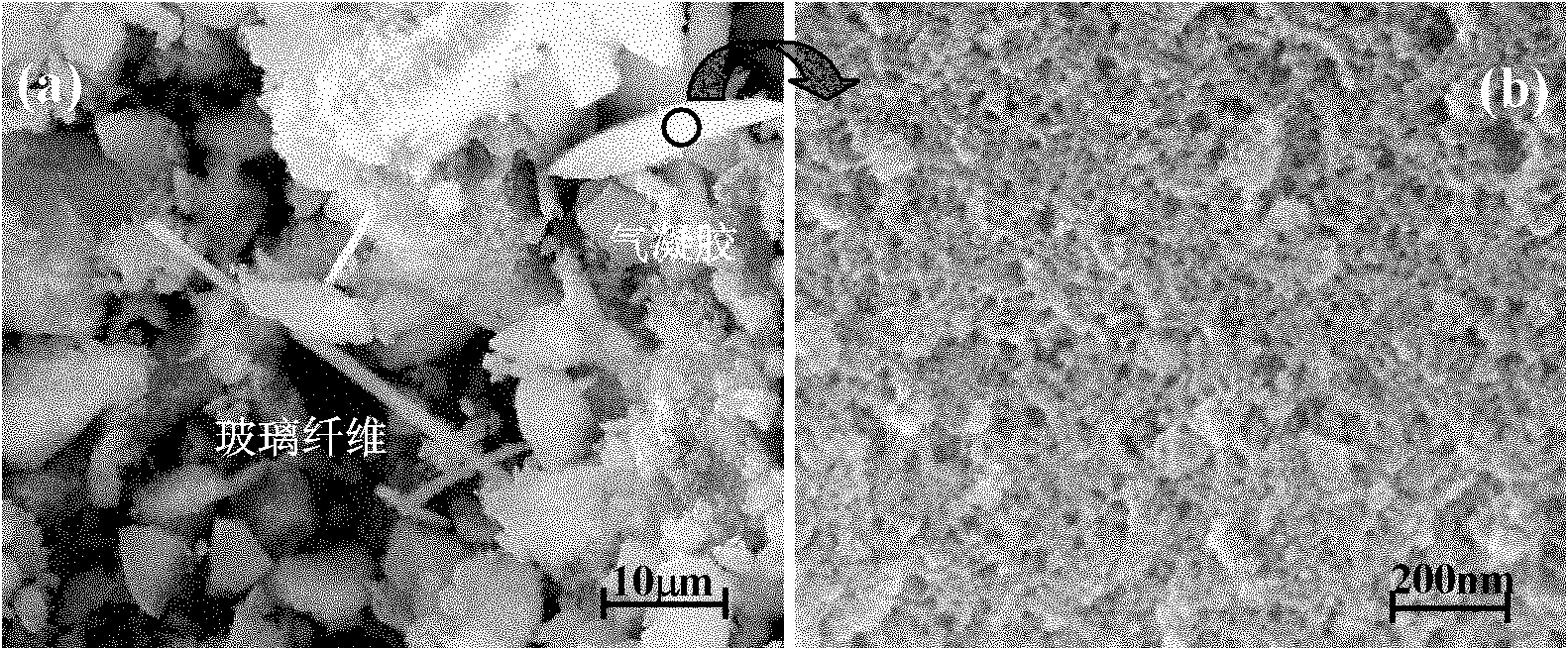

Embodiment 1

[0034] First, take 0.05g of glass fiber and heat-treat it at 110°C for 30 minutes, then add it into the mixed solution of KH-550 coupling agent and an appropriate amount of absolute ethanol, stir for 3 hours, dry it at 120°C and take it out for use. The dosage is 0.2% of the fiber mass. Take ethyl orthosilicate, methyltriethoxysilane, absolute ethanol, water, and hydrochloric acid alcohol solution in volumes of 5.5ml, 2ml, 10ml, 2.5ml, and 0.4ml for mixed reaction, and add silanized Glass fiber, keep stirring and add ammonia water alcohol solution after 4h, adjust pH ≈ 8.0, wait for gel. The composite wet gel was immersed in absolute ethanol and aged at 55°C for 1 day. After aging, the wet gel was immersed in a mixed surface modifier solution containing 4ml TMCS, 4ml absolute ethanol, and 36ml n-hexane, and modified at 35°C. After 2 days of resistance, the composite wet gel was taken out and cleaned, and often pressed and dried to obtain a glass fiber reinforced silica compos...

Embodiment 2

[0036] First, take 0.1g of glass fiber and heat-treat it at 110°C for 30 minutes, then add it into the mixed solution of KH-550 coupling agent and an appropriate amount of absolute ethanol, stir for 3 hours, dry it at 120°C and take it out for use. The dosage is 0.5% of the fiber mass. Take ethyl orthosilicate, methyltriethoxysilane, absolute ethanol, water, and hydrochloric acid alcohol solution in volumes of 5.5ml, 2ml, 12ml, 3ml, and 0.5ml for mixed reaction, and add silanized glass after 8 hours Fiber, after 4h, add ammonia water alcohol solution, adjust pH ≈ 8.0, and wait for gelation. Then the composite wet gel was immersed in absolute ethanol and aged at 55°C for 1 day. After aging, the wet gel was immersed in a mixed surface modifier solution containing 4ml TMCS, 4ml absolute ethanol, and 32ml n-hexane at 35°C. After 2 days of modification, the wet gel was taken out, washed with n-hexane, and dried under constant pressure to obtain a glass fiber reinforced silica comp...

Embodiment 3

[0038] First, take 0.1g of glass fiber and heat-treat it at 110°C for 30 minutes, then add it into the mixed solution of KH-550 coupling agent and an appropriate amount of absolute ethanol, stir for 3 hours, dry it at 120°C and take it out for use. The dosage is 0.2% of the fiber mass. Take ethyl orthosilicate, methyltrimethoxysilane, absolute ethanol, water, and hydrochloric acid alcohol solution in volumes of 5.5ml, 2ml, 12.5ml, 3ml, and 0.4ml for mixed reaction, and add the treated glass fiber after 8 hours , Stir, and after 4h, add ammonia water alcohol solution, adjust the pH ≈ 8.3, and wait for the gel. Then the composite wet gel was immersed in absolute ethanol and aged at 50°C for 2 days. After aging, the wet gel was immersed in a mixed surface modifier solution containing 4ml TMCS, 4ml absolute ethanol, and 40ml n-hexane at 35°C. After 2.5 days of modification, the wet gel was taken out, washed with n-hexane to remove the modifier remaining on the surface, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com