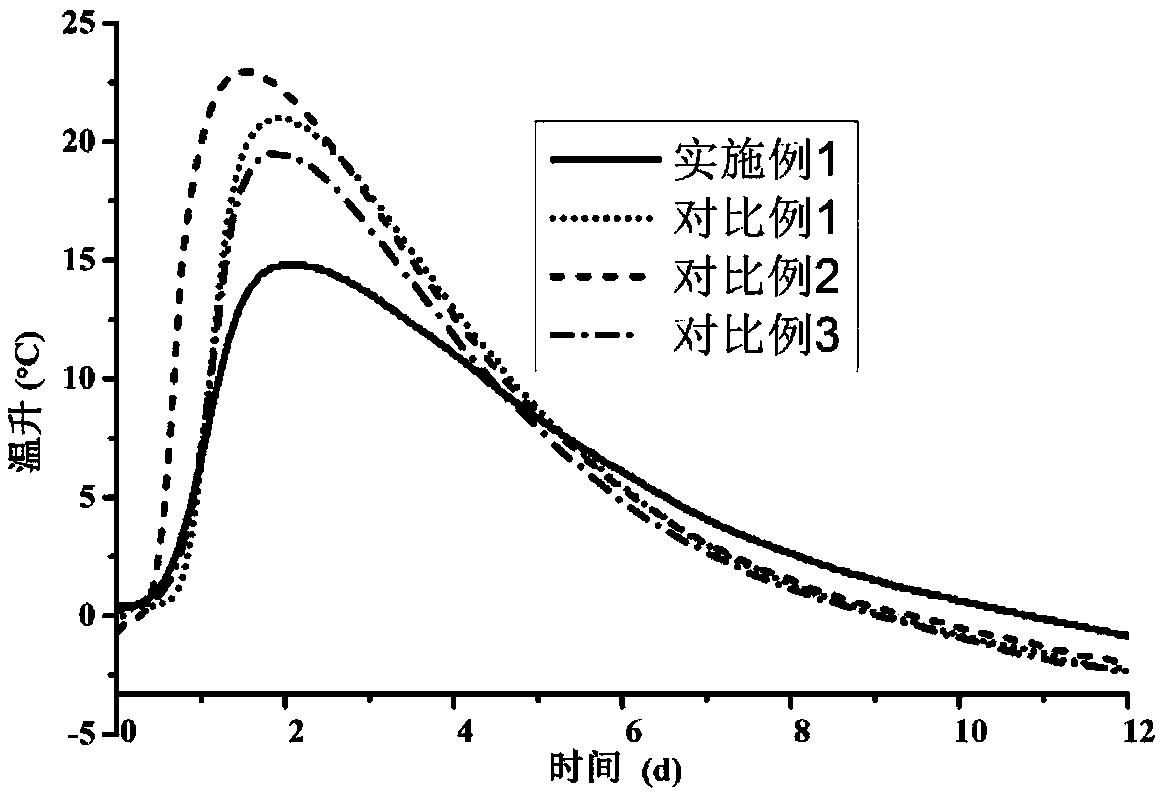

Mass concrete hydration temperature rise inhibitor as well as preparation method and application thereof

A technology of mass concrete and inhibitor, which is applied in the field of concrete anti-cracking temperature control admixture and the hydration temperature rise inhibitor of mass concrete, which can solve the problem of difficulty in reducing temperature peaks and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 10g of paraffin wax with melting points of 30°C, 40°C, and 70°C into the flask, heat to 80°C to melt, keep the temperature and add 65g of porous ceramsite, mix well, lower the temperature to 30°C, add 5g of number average molecular weight Be the starch polysaccharide of 5000-20000, obtain product embodiment 1 after mixing.

Embodiment 2

[0020] Add 5g of paraffin wax with a melting point of 60°C and 5g of barium hydroxide octahydrate into the flask, heat to 90°C to melt, keep the temperature and add 70g of porous ceramsite, mix well, lower the temperature to 30°C, add 20g of number average molecular weight Be the starch polysaccharide of 5000-30000, obtain product embodiment 2 after mixing.

Embodiment 3

[0022] Add 10g of barium hydroxide octahydrate to the flask, heat it to 90°C to melt it, keep the temperature and add 85g of porous ceramsite, after mixing evenly, lower the temperature to 30°C, add 5g of starch polymer with a number average molecular weight of 10000-30000 Sugar, after mixing, product embodiment 3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com