Proton exchange fuel cell

A fuel cell and proton exchange technology, used in fuel cells, fuel cell components, circuits, etc., can solve problems such as limited battery power generation efficiency, affecting coolant heat exchange efficiency, affecting fluid fuel reaction speed and reaction sufficiency, etc. , to achieve the effect of improving the reaction speed and reaction sufficiency, improving the power generation efficiency, and enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

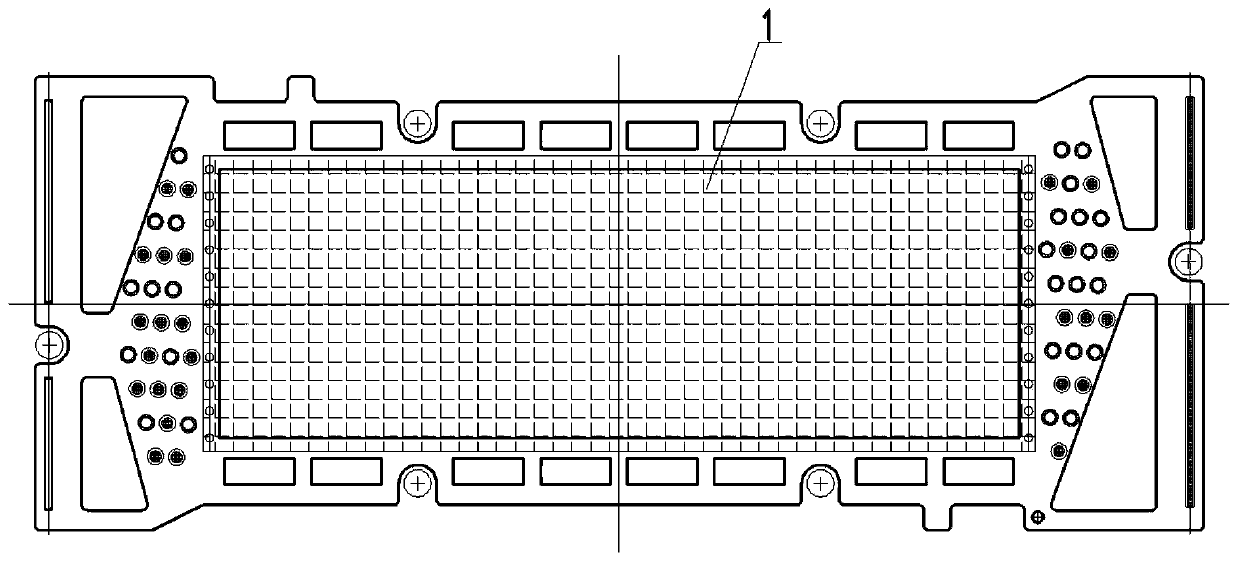

[0025] The present invention will be further described below in conjunction with specific drawings.

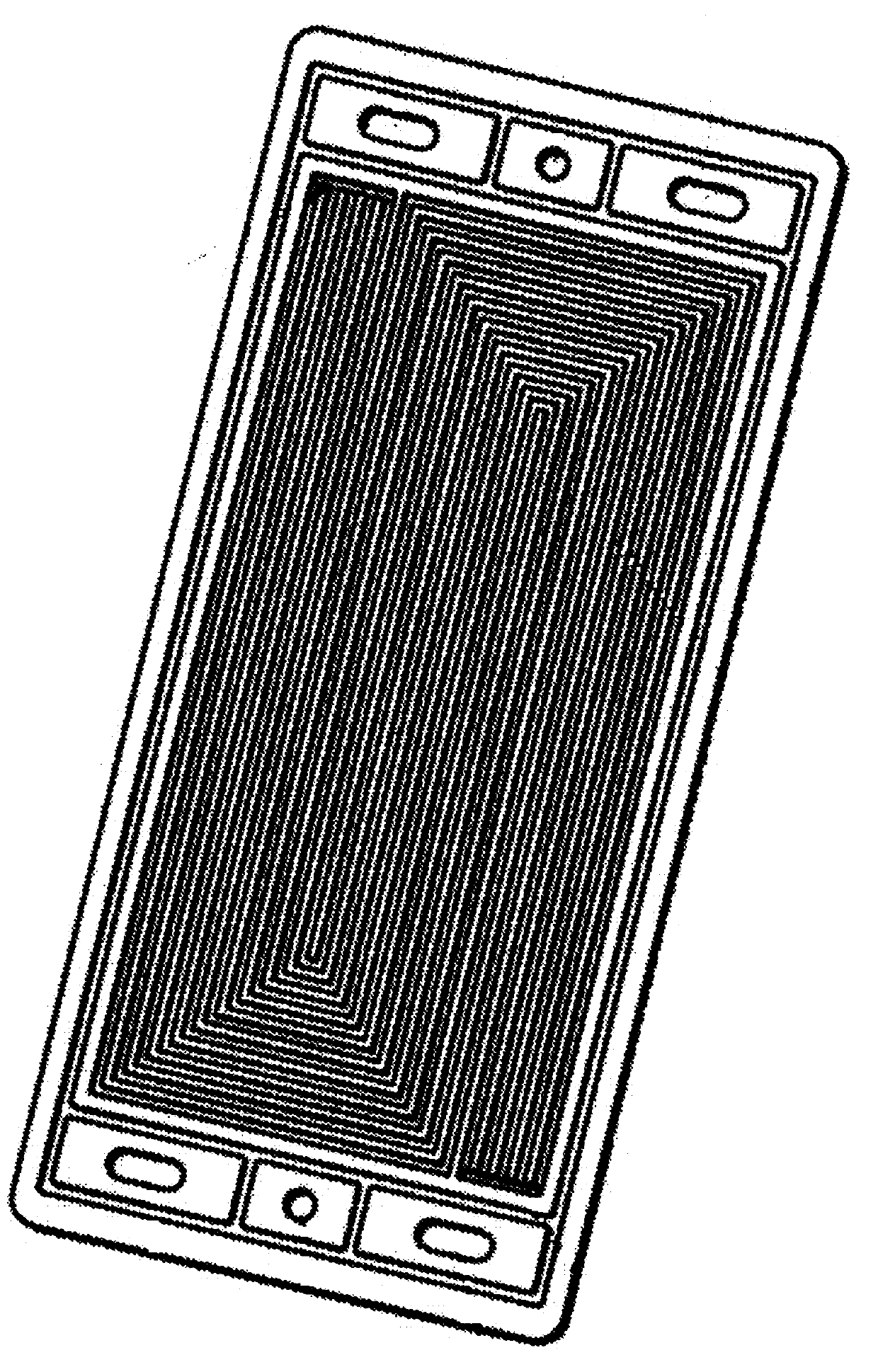

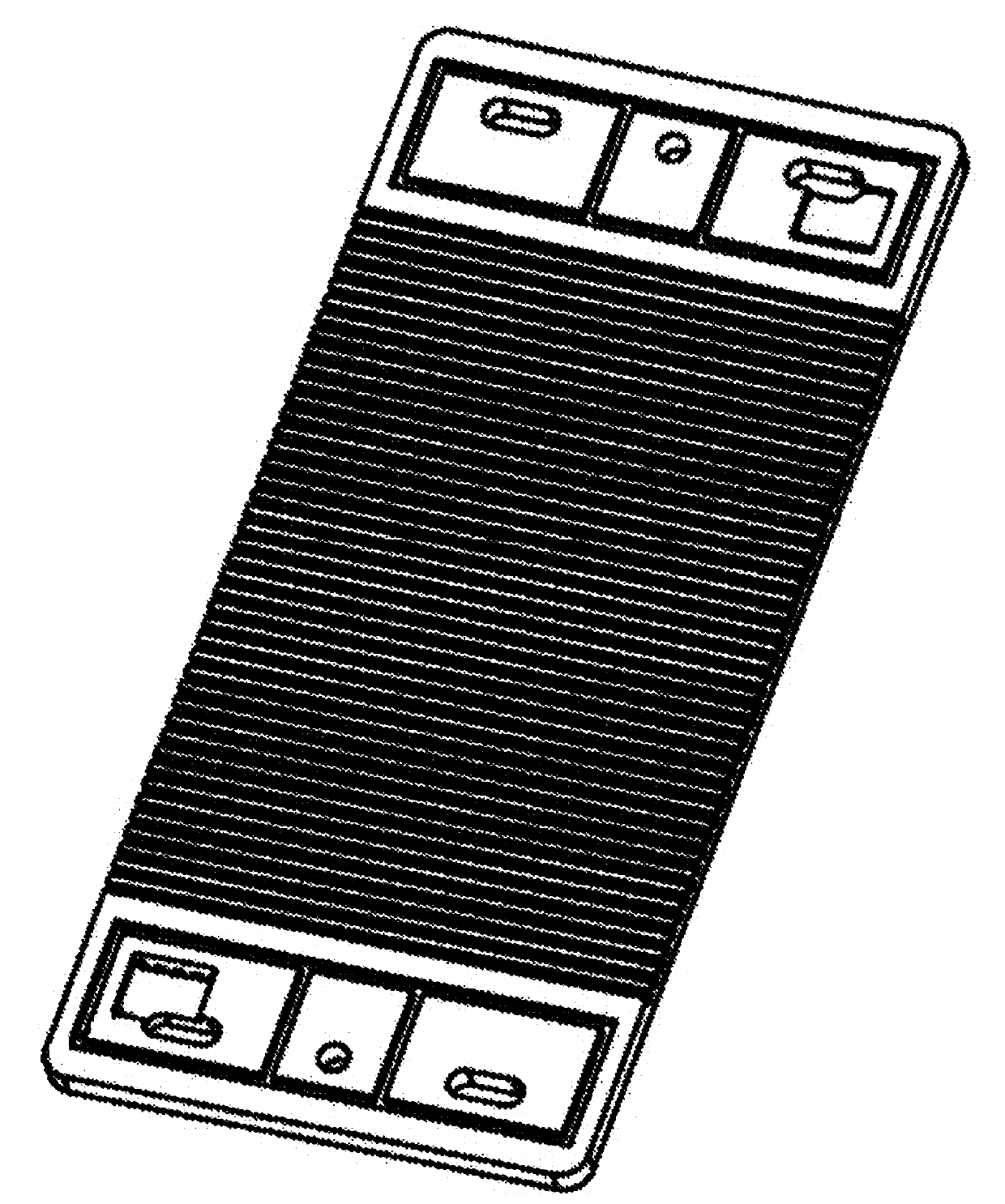

[0026] image 3 A schematic structural diagram of a proton exchange fuel cell in the present invention is shown, which is composed of a plurality of interconnected single cells 1 . The single cell 1 is mainly composed of an anode plate 11, a cathode plate 12, and a proton exchange membrane 13, among which the anode plate 11 and the cathode plate 12 are electrochemical reaction sites where the fuel oxidation reaction and the oxidant reduction reaction occur. The key to the quality of the electrode lies in the performance of the catalyst, the material of the electrode and the process of the electrode. The proton exchange membrane 13 is arranged between the anode plate 11 and the cathode plate 12, and the anode plate 11 is connected in parallel to the negative pole of the battery through a wire, and the cathode plate 12 is connected in parallel to the positive pole of the batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com