Method for growing semi-polar GaN based on Al2O3 substrate with m sides

A semi-polar, substrate technology, applied in the field of microelectronics, can solve the problems of increasing process flow and low efficiency, and achieve the effect of improving luminous efficiency, high efficiency, and reducing the influence of mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

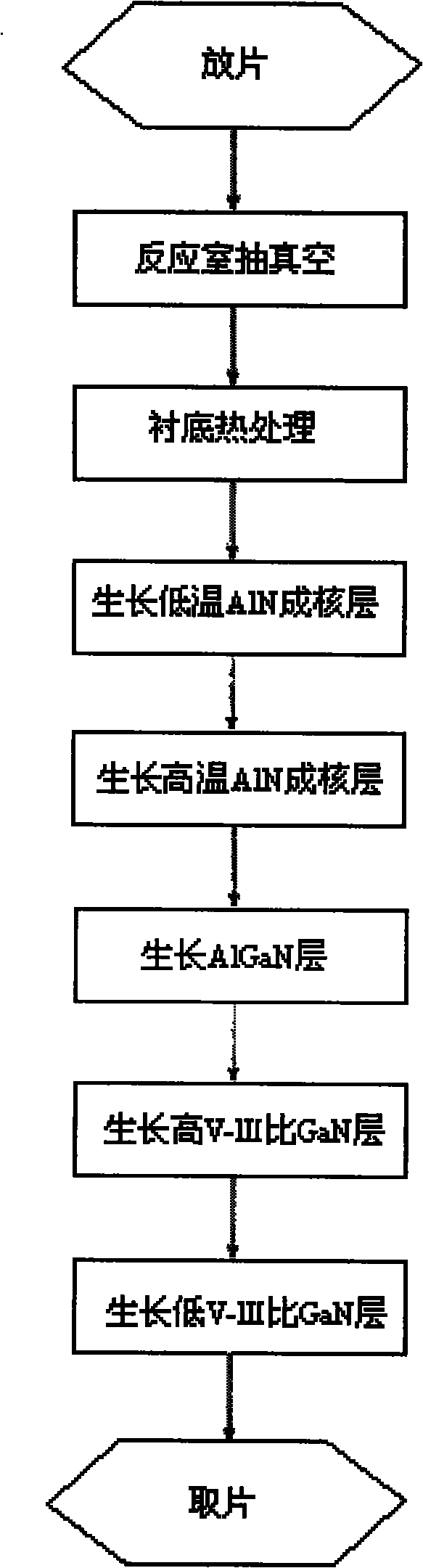

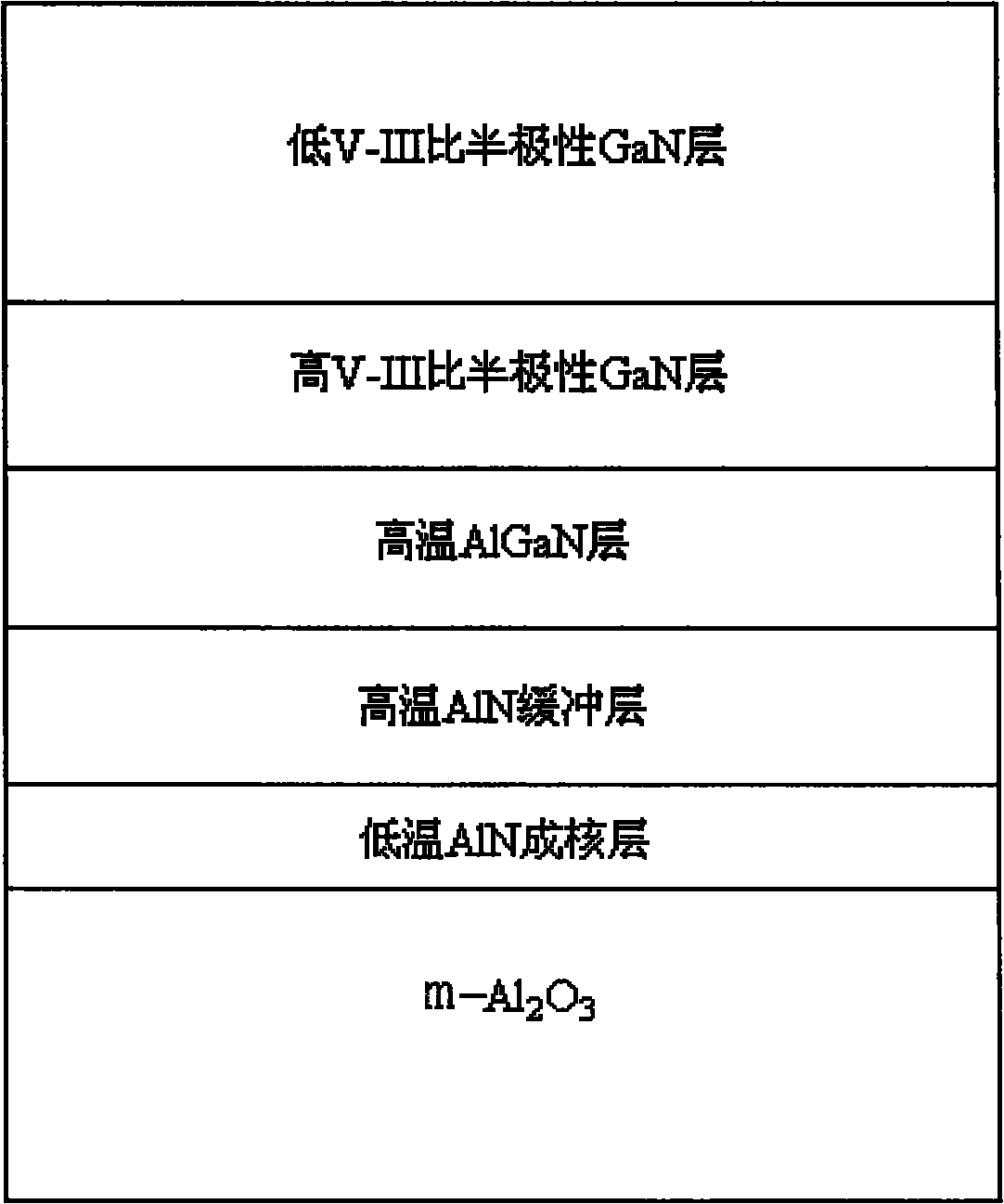

Method used

Image

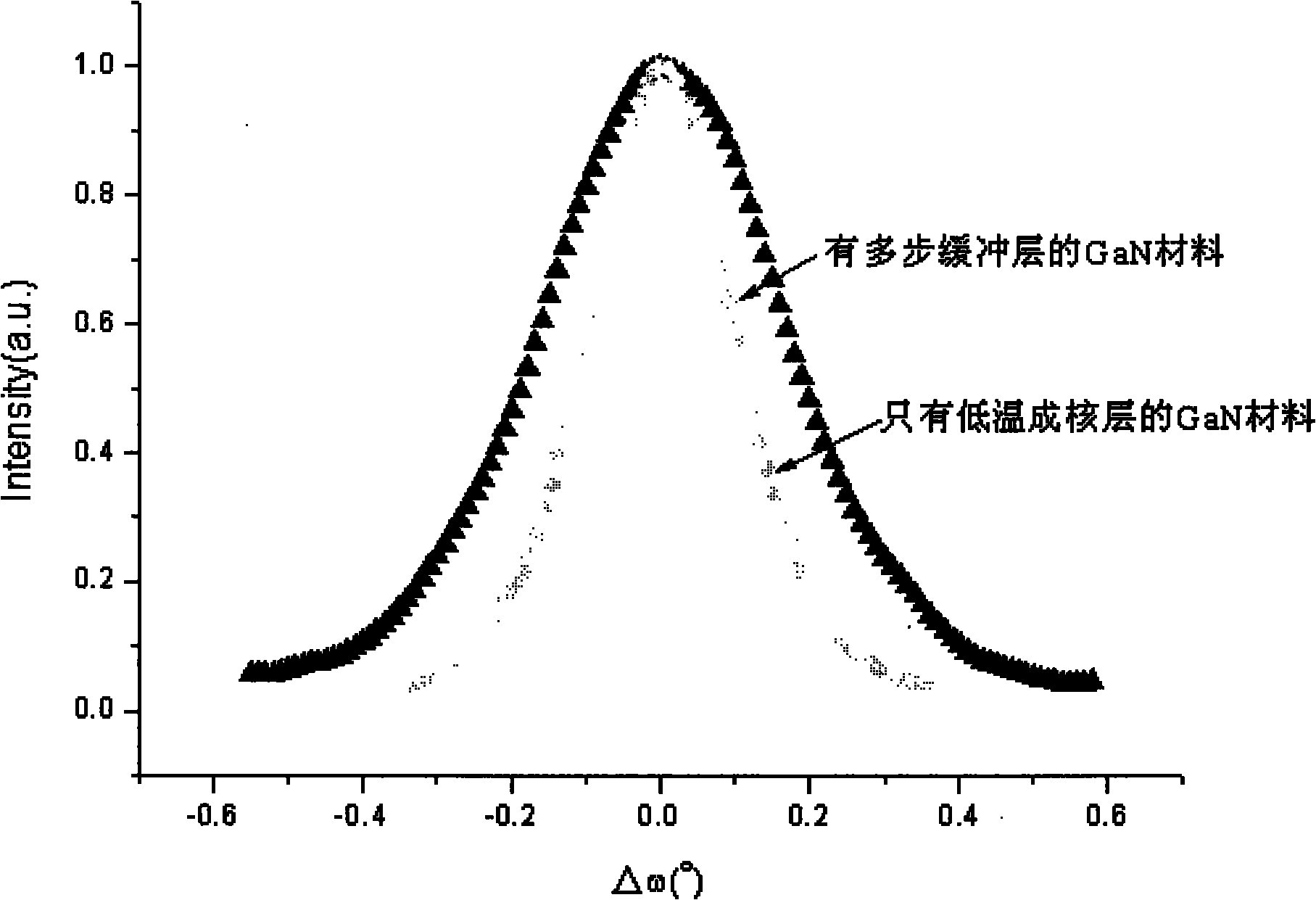

Examples

Embodiment 1

[0023] Step 1, performing heat treatment on the substrate substrate.

[0024] Al 2 o 3 The substrate is placed in the metal organic compound chemical vapor deposition MOCVD reaction chamber, and the mixed gas of hydrogen and ammonia is introduced into the reaction chamber, and the vacuum degree in the reaction chamber is less than 2×10 -2 Torr, under the condition that the substrate heating temperature is 1100° C., the time is 8 minutes, and the pressure of the reaction chamber is 40 Torr, heat treatment is performed on the substrate.

[0025] Step 2, growing a low-temperature AlN layer.

[0026] Lower the temperature of the heat-treated substrate to 620°C, feed the aluminum source with a flow rate of 15 μmol / min, hydrogen gas with a flow rate of 1200 sccm and ammonia gas with a flow rate of 1500 sccm into the reaction chamber, and grow the thickness under the condition of maintaining a pressure of 40 Torr A low temperature AlN nucleation layer of 20nm.

[0027] Step 3, gr...

Embodiment 2

[0037] Step A, performing heat treatment on the base substrate.

[0038] Al 2 o 3 The substrate is placed in the metal organic compound chemical vapor deposition MOCVD reaction chamber, and the mixed gas of hydrogen and ammonia is introduced into the reaction chamber, and the vacuum degree in the reaction chamber is less than 2×10 -2 Torr, under the condition that the substrate heating temperature is 900° C., the time is 5 minutes, and the pressure of the reaction chamber is 20 Torr, heat treatment is performed on the substrate.

[0039] Step B, growing a low-temperature AlN layer.

[0040] Lower the temperature of the heat-treated substrate to 500°C, feed the aluminum source with a flow rate of 5 μmol / min, hydrogen gas with a flow rate of 1200 sccm, and ammonia gas with a flow rate of 1000 sccm into the reaction chamber, and grow thickness under the condition of maintaining a pressure of 20 Torr A low temperature AlN nucleation layer of 20nm.

[0041]Step C, growing a hig...

Embodiment 3

[0051] Step I, heat-treating the base substrate.

[0052] Al 2 o 3 The substrate is placed in the metal organic compound chemical vapor deposition MOCVD reaction chamber, and the mixed gas of hydrogen and ammonia is introduced into the reaction chamber, and the vacuum degree in the reaction chamber is less than 2×10 -2 Torr, under the condition that the substrate heating temperature is 1200° C., the time is 10 min, and the pressure of the reaction chamber is 760 Torr, heat treatment is performed on the substrate.

[0053] Step II, growing a low-temperature AlN layer.

[0054] Lower the temperature of the heat-treated substrate to 650°C, feed the aluminum source with a flow rate of 100 μmol / min, hydrogen gas with a flow rate of 1200 sccm, and ammonia gas with a flow rate of 10000 sccm into the reaction chamber, and grow the thickness under the condition of maintaining a pressure of 760 Torr A low temperature AlN nucleation layer of 200nm.

[0055] Step III, growing a high t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com