Hydraulic control natural gas hydrate hole bottom frozen rope core drill and coring method

A technology for core drilling tools and hydrates, applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve problems such as difficult implementation, poor feasibility, and unguaranteed reliability, so as to improve the core recovery rate and high feasibility , good freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

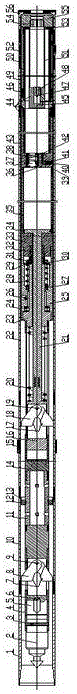

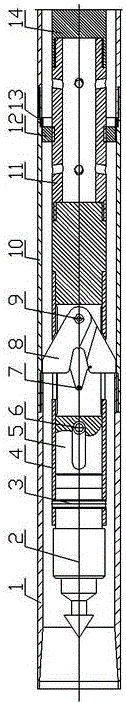

[0034] Such as figure 1 As shown, in this embodiment, dry ice is used as the cold source, and alcohol is used as the cooling aid catalyst and the refrigerant; dry ice is used as the cold source, and alcohol is used as the cooling aid catalyst and the refrigerant. The embodiment is composed of the inner pipe assembly and the outer pipe assembly. The inner tube assembly includes a salvage mechanism, an ejector positioning mechanism, a suspension mechanism, a movable cartridge mechanism, a single-action mechanism, an adjustment mechanism, a cold source storage mechanism and a hole bottom freezing mechanism;

[0035] The salvage mechanism is composed of a fishing spear head 2, a first elastic pin 3 and a first bullet card recovery pipe 4, and the fishing spear head 2 is connected with the first bullet card recovery pipe 4 through the first elastic pin 3; The spear head 2 is connected, and the process of putting the inner tube assembly of the drilling tool into the hole and recover...

Embodiment 2

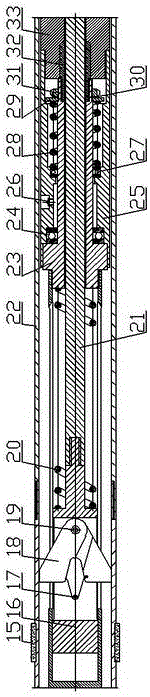

[0052] Such as Figure 5 As shown, this embodiment adopts a mixture of alcohol and dry ice as a cold source or a phase-change fluid such as liquid nitrogen that can quickly vaporize and absorb heat as a cold source. This embodiment is composed of two parts: an inner tube assembly and an outer tube assembly Large composition, the inner tube assembly includes: salvage mechanism, bullet positioning mechanism, suspension mechanism, movable bullet mechanism, single-action mechanism, adjustment mechanism, cold source storage mechanism and hole bottom freezing mechanism. Wherein the salvage mechanism, the cartridge positioning mechanism, the suspension mechanism, the movable cartridge mechanism, the single-action mechanism, the regulating mechanism and the hole bottom freezing mechanism are the same as those in Embodiment 1.

[0053] The cold source storage mechanism is composed of an upper handle 33 in the alcohol cavity, an alcohol cavity body pipe 35, a lower handle 36 in the alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com