Hot water core drill used at glacier

A technology of core drilling and hot water, which is applied in ice drilling, application of thermal energy drilling, drilling equipment, etc., to save costs and improve energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

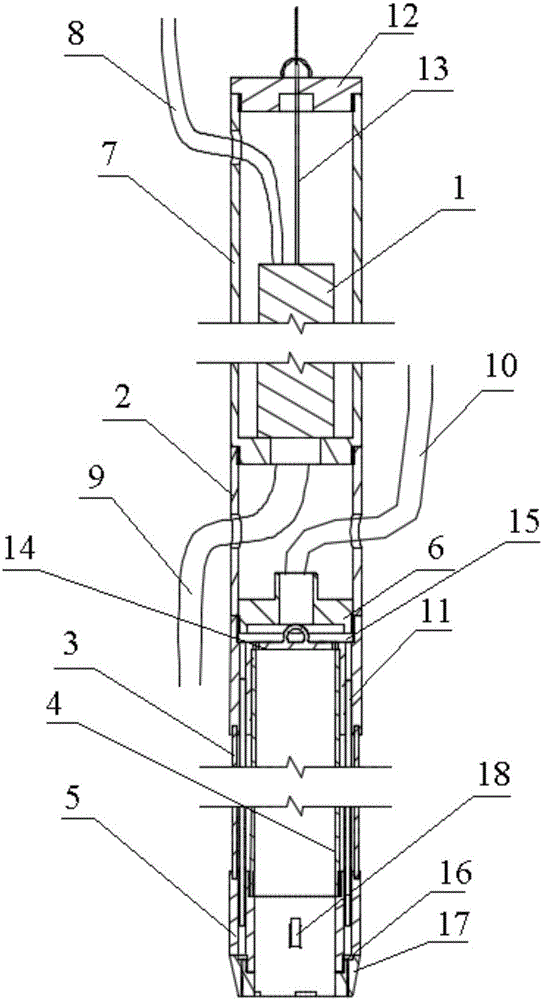

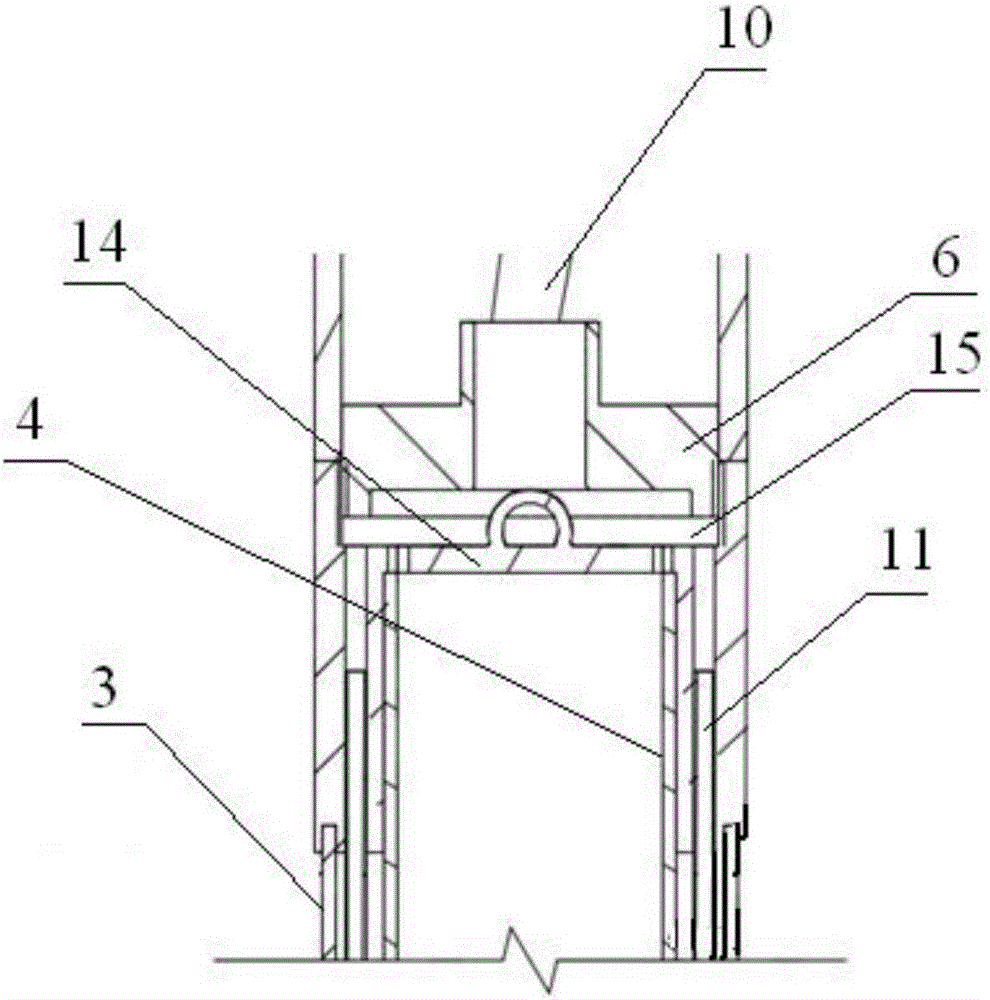

[0021] see figure 1 and figure 2 Shown:

[0022] The hot water core drilling tool used in glacier provided by the present invention comprises plunger pump 1, double-way pipe 2, heat insulation pipe 3, ice core pipe 4, drill bit 5 and diverter 6, and wherein plunger pump 1 is located at In the storage pump pipe 7, the upper end of the plunger pump 1 is connected with an outlet pipe 8, the lower end of the plunger pump 1 is connected with a water suction pipe 9, the double-way pipe 2 is connected with the lower end of the storage pump pipe 7, and the lower end of the double-way pipe 2 is connected with the The heat insulation pipe 3 is connected, the ice core pipe 4 is inserted in the heat insulation pipe 3, the drill bit 5 is set at the lower part of the heat insulation pipe 3 and the ice core pipe 4, and the flow divider 6 is set at the lower part of the double-way pipe 2 and the ice core pipe 4 The top of the flow divider 6 is connected with a hot water injection pipe 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com