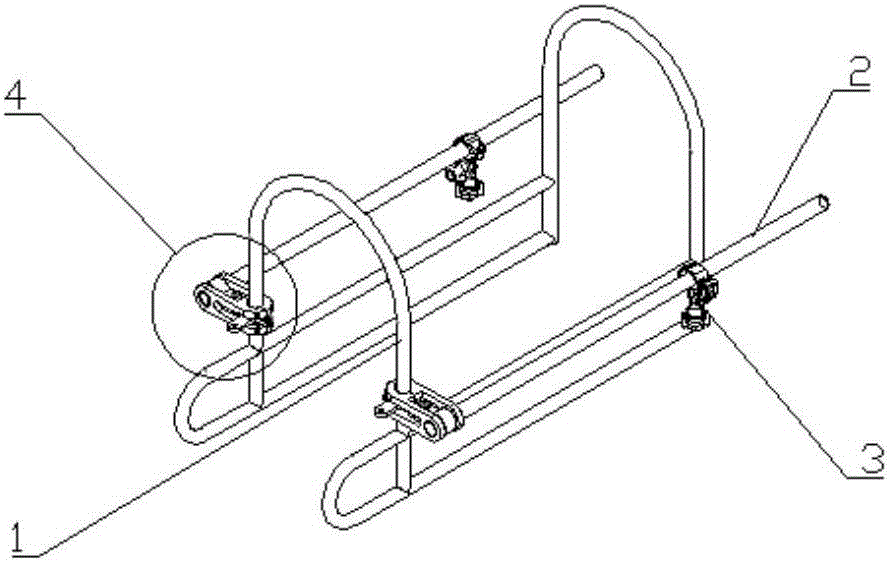

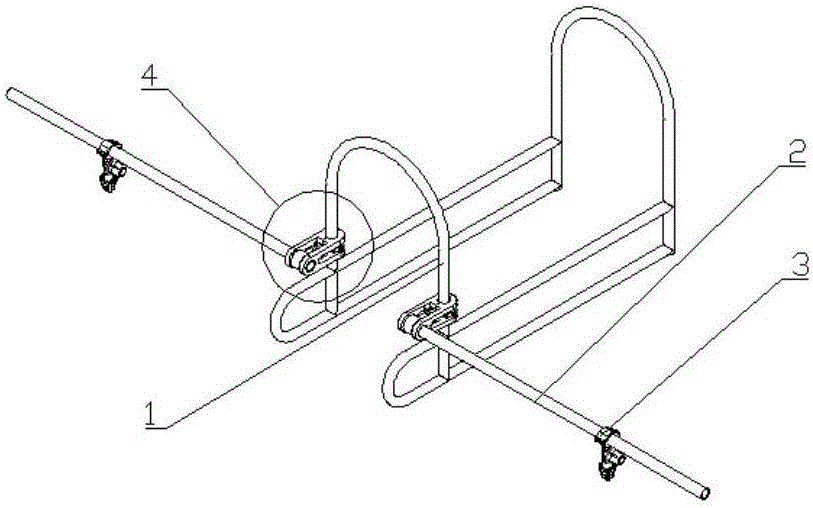

Electrostatic spraying device of plant protection unmanned aerial vehicle

A technology for planting and protecting drones and electrostatic spraying, which is applied to spray devices, launch devices, aircraft parts, etc., can solve problems such as the inability to adjust the spacing of nozzles, reduce operating time and material costs, improve uniformity, and improve operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

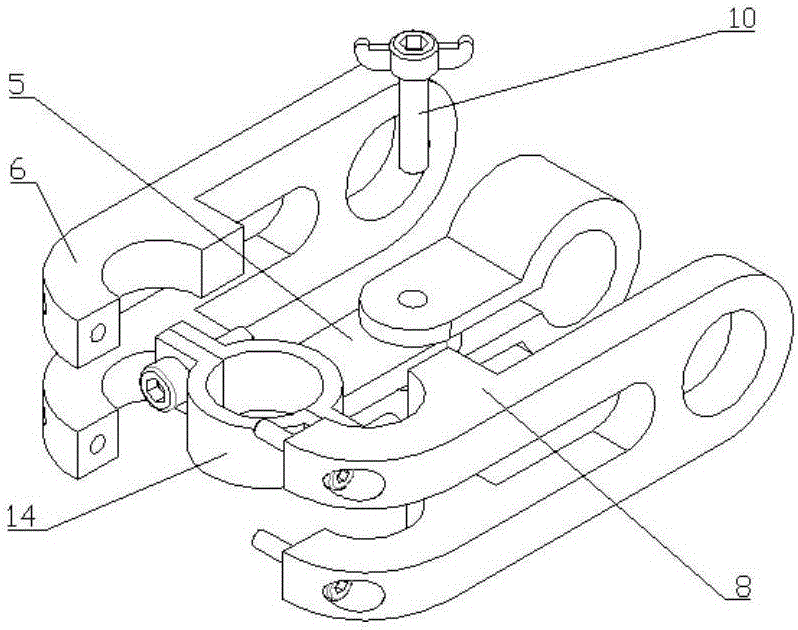

[0024] When working in farmland, the plant size and planting row spacing are different, and the nozzle spacing should be adjusted for specific field operations. Before the aviation spraying operation, the spray boom 2 is positioned on the vertical rod member of the front arch of the landing gear 1 by the spacing adjustment device 4, and the spray boom 2 is folded on both sides of the landing gear. According to parameters such as specific field plants and row spacing, select a suitable nozzle 3 and move the spray bars 2 on both sides axially to obtain a suitable nozzle spacing. After the spacing adjustment is completed, the spray boom 2 is deployed to the working position. There is a gap between the positioning part 14 of the landing gear and the pressure plate of the spray boom fastening ring 11. When the set screw 10 is inserted into the positioning screw hole of the pressure plate of the spray boom fastening ring 11 and tightened, the two pressure plates of the spray boom fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com