Multifunctional overhauling platform

An overhaul platform and multi-functional technology, applied in switchgear, electrical components, etc., can solve the problems of center of gravity shift, effective span reduction, and difficult control of safety and stability, so as to improve safety and avoid unstable conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

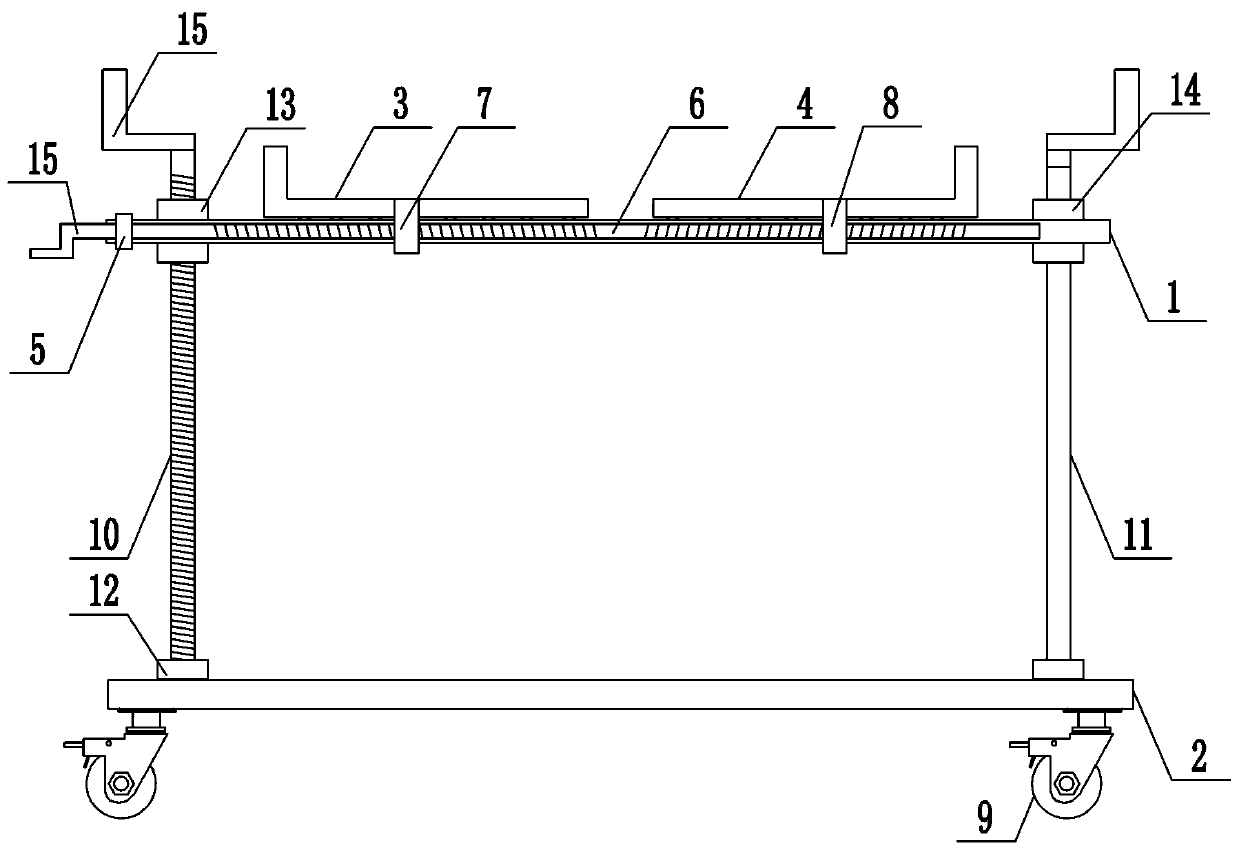

[0029] like figure 1 As shown, the present invention discloses a multifunctional maintenance platform, which includes a width adjustment mechanism, a support plate 1, a height adjustment mechanism, a bottom plate 2 and a moving assembly from top to bottom. Plate 3 and the second moving plate 4, the sliding mode of the supporting plate 1 and the first moving plate 3 and the second moving plate 4 can be adopted: a plurality of rollers are arranged on the upper end surface of the supporting plate 1, and a sliding arrangement with the supporting plate 1 The lower end surfaces of the first moving plate 3 and the second moving plate 4 are in sliding contact with the rollers, and the first moving plate 3 and the second moving plate 4 are both L-shaped structures;

[0030] The edge of the support plate 1 is provided with two second bearings 5, and the second bearing 5 is rotatably connected to the second threaded rod 6, and the same edge of the two moving plates is respectively provid...

Embodiment 2

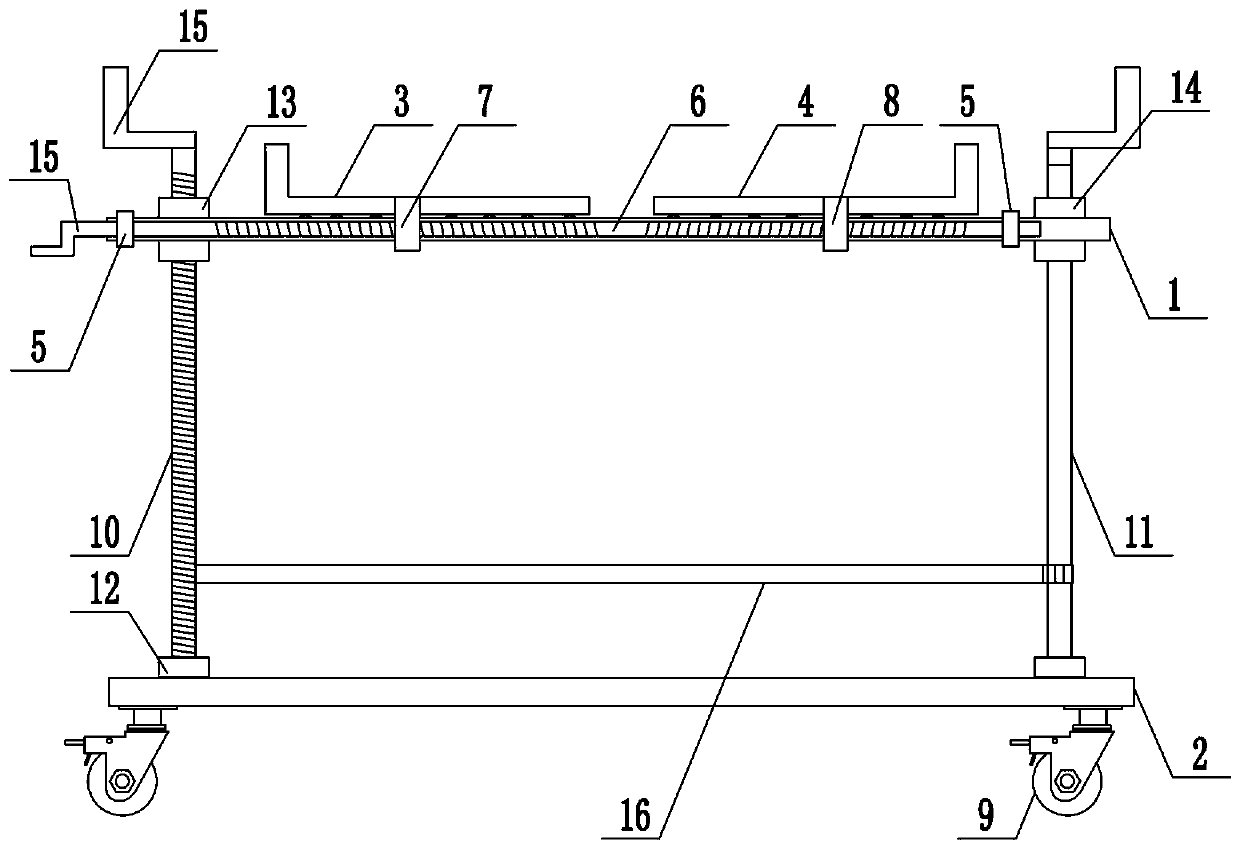

[0035] like figure 2 As shown, the present invention discloses a multifunctional maintenance platform, which includes a width adjustment mechanism, a support plate 1, a height adjustment mechanism, a bottom plate 2 and a moving assembly from top to bottom. Plate 3 and the second moving plate 4, the sliding mode of the supporting plate 1 and the first moving plate 3 and the second moving plate 4 can be adopted: a plurality of rollers are arranged on the upper end surface of the supporting plate 1, and a sliding arrangement with the supporting plate 1 The lower end surfaces of the first moving plate 3 and the second moving plate 4 are in sliding contact with the rollers, and the first moving plate 3 and the second moving plate 4 are both L-shaped structures;

[0036] The edge of the support plate 1 is provided with two second bearings 5, and the second bearing 5 is rotatably connected to the second threaded rod 6, and the same edge of the two moving plates is respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com