Multi-station machining device for pressure sensor manufacturing

A pressure sensor and processing device technology, applied in the direction of manufacturing tools, worktables, etc., can solve the problems of inability to adjust the size of the sensor, waste of manpower, inconvenience for operators, etc., and achieve the effect of increasing practicability and improving universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

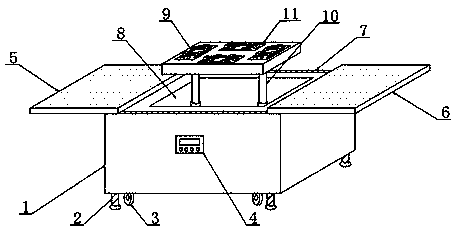

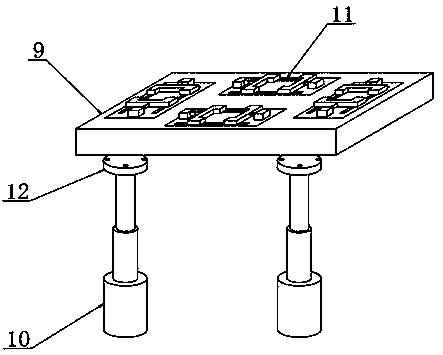

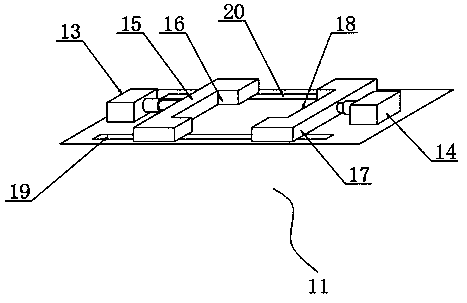

[0023] see Figure 1~4 , in an embodiment of the present invention, a multi-station processing device for manufacturing a pressure sensor includes a frame 1, the bottom end of the frame 1 is fixedly installed with an adjustment leg 2, and the bottom end of the frame 1 is located at the bottom of the adjustment leg 2 A universal wheel 3 is provided on one side of the frame, a control panel 4 is embedded in the front side of the frame 1, a MAM-200 controller is provided inside the control panel 4, and a first panel is provided on the top side of the frame 1 5. The second panel 6 is installed on the other side, and the top of the frame 1 is provided with an accommodation cavity 8, and the connection between the frame 1 and the first panel 5 and the second panel 6 is provided with a slide rail 7, and the slide rail 7 has a total of There are two slide rails 7 arranged in parallel, the first panel 5 and the second panel 6 and the frame 1 are slidingly connected through the slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com